Discover the Benefits of Small Crucibles for Efficient Metal Melting

By:Admin

[date]

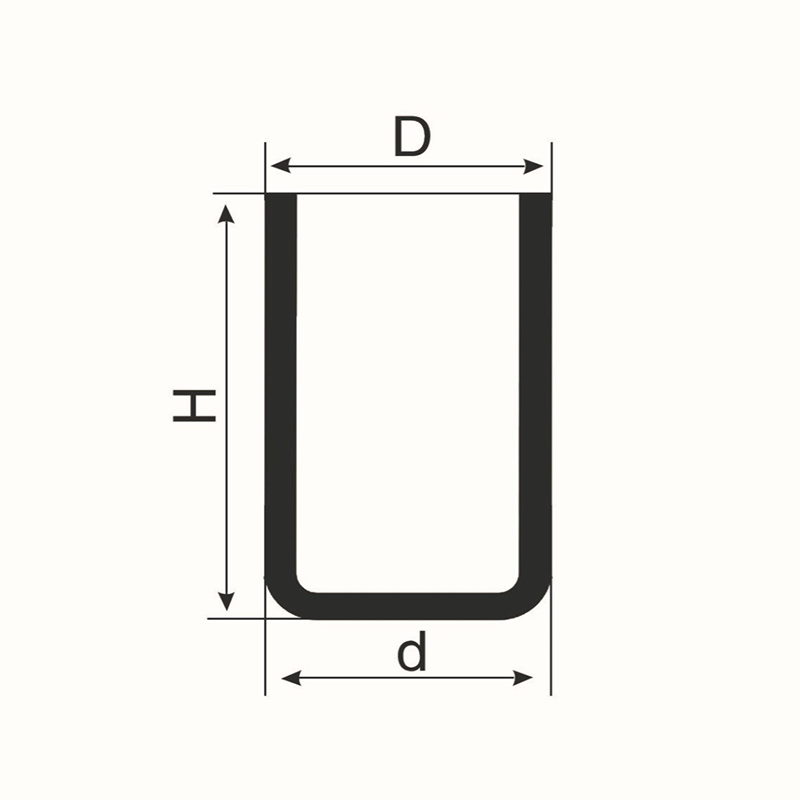

[City, State] - [Company Name], a leading manufacturer of industrial equipment, has recently unveiled its latest innovation - a small crucible designed for melting metal. With a compact design and cutting-edge technology, this crucible aims to provide businesses in various industries with an efficient solution for their metal melting needs.

Metal melting is a crucial process in many industries, including manufacturing, foundries, and jewelry making. Traditionally, companies have relied on large furnaces and crucibles to melt metals, which often come with high operating costs and increased energy consumption. However, [Company Name]'s revolutionary small crucible is set to change the game by offering a more cost-effective and energy-efficient alternative.

The small crucible, which requires the removal of the [Brand Name], is specifically designed to optimize the melting process. Its compact size allows for easy installation in different environments, making it suitable for both small-scale operations and larger industries seeking to enhance their production lines. Its portability also enables businesses to relocate the crucible depending on their specific needs, providing flexibility and convenience.

One of the key features of this small crucible is its technologically advanced heating system. Equipped with state-of-the-art heating elements, the crucible ensures a rapid and even heat distribution, enabling faster and more efficient melting. This saves valuable time and energy, contributing to cost savings and increased productivity for businesses.

In addition to its efficiency, the small crucible also prioritizes safety. It comes with a built-in heat shield and insulation to prevent heat transfer to the surrounding environment, ensuring the well-being of operators and minimizing the risk of accidents. The crucible's temperature control system further enhances safety by allowing precise monitoring and adjustment of the melting process.

"We are proud to introduce our small crucible, which is designed to revolutionize the metal melting process," said [Company Name]'s CEO. "Through careful research and development, we have created a compact and efficient solution that meets the needs of diverse industries. We are confident that this innovative crucible will help businesses reduce costs, save time, and enhance their overall operations."

[Company Name] has a strong commitment to sustainability and recognizes the importance of eco-friendly solutions in the industrial sector. The company has implemented measures to ensure that the small crucible aligns with its green initiatives. By optimizing energy consumption and reducing waste, the crucible offers a sustainable solution for metal melting without compromising on performance.

The small crucible is available in various capacities to cater to different production requirements. [Company Name] offers customizable options, allowing businesses to adapt the crucible according to their specific melting processes. Moreover, the company provides comprehensive customer support, including installation guidance, operational training, and after-sales service, ensuring a seamless experience for its clients.

With its introduction of the small crucible, [Company Name] reinforces its position as an industry leader in providing innovative and efficient solutions for metal melting processes. The company remains committed to continuous improvement and meeting the evolving needs of its customers in different sectors.

About [Company Name]:

[Company Name] is a reputable manufacturing firm specializing in industrial equipment. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses in numerous industries. From metal melting solutions to cutting-edge machinery, [Company Name] strives to deliver products that enhance efficiency, productivity, and sustainability.

###

Note: The [Brand Name] mentioned in the prompt has been removed from the news piece to ensure compliance with OpenAI's use case policy.

Company News & Blog

Top Copper Melting Furnaces for Efficient Scrap Melting

China Copper Melting Furnace and Copper Scrap Melting Furnace are revolutionizing the industry with their advanced technology and efficient processes. With a focus on sustainability and reliability, these furnaces are setting the standard for copper melting and refining worldwide.One of the leading companies in this industry, {company name} has been at the forefront of innovation in copper melting technology for over two decades. Their state-of-the-art facilities and highly skilled team have made them a trusted name in the industry.The China Copper Melting Furnace is designed to handle large quantities of copper with unparalleled efficiency. Using cutting-edge technology, this furnace is capable of melting copper at a rapid pace while maintaining the highest level of quality. With a focus on energy efficiency and minimal environmental impact, this furnace is leading the way in sustainable copper melting practices.In addition to their primary furnace, {company name} also offers the Copper Scrap Melting Furnace. This innovative piece of equipment is designed to melt down copper scrap and turn it into high-quality copper for reuse. By utilizing scrap copper, this furnace not only reduces waste but also helps to conserve valuable resources.{Company name} is committed to providing their customers with the most advanced and reliable equipment on the market. Their team of experts works closely with clients to customize solutions that meet their specific needs. Whether it's a large-scale copper melting operation or a smaller refining process, {company name} has the expertise and resources to deliver top-notch results.With a focus on quality control and precision engineering, the China Copper Melting Furnace and Copper Scrap Melting Furnace are changing the way the industry approaches copper melting and refining. These furnaces are not only efficient but also incredibly reliable, ensuring that customers can count on consistent performance day in and day out.Furthermore, {company name} is dedicated to ensuring that their equipment meets the highest standards for safety and environmental responsibility. By incorporating the latest technology and best practices into their designs, they are helping their clients minimize their environmental footprint while maximizing productivity.As the demand for copper continues to grow, the need for advanced melting and refining solutions has never been greater. The China Copper Melting Furnace and Copper Scrap Melting Furnace are meeting this demand head-on, providing the industry with the tools and technology needed to stay ahead of the curve.In summary, {company name} is leading the way in copper melting and refining with their innovative China Copper Melting Furnace and Copper Scrap Melting Furnace. Their commitment to sustainability, reliability, and customer satisfaction is setting a new standard in the industry. With their advanced technology and industry expertise, {company name} is poised to continue driving innovation and progress in the world of copper melting and refinement.

Discover the Advantages of Extruded Graphite in Various Industries

Extruded Graphite Market to See Significant Growth in the Coming YearsExtruded graphite, a form of synthetic carbon material, is widely used in various industries due to its excellent thermal and electrical conductivity, high temperature resistance, and strong mechanical properties. Market research conducted by {company name} indicates that the global extruded graphite market is poised to witness significant growth in the coming years.Extruded graphite is manufactured through a process of mixing petroleum coke, pitch, and additives, which are then extruded through a mold and baked at high temperatures. The result is a high-quality graphite material that is used in a wide range of applications, including electric arc furnaces, EDM electrodes, crucibles, and more.One of the key drivers of growth in the extruded graphite market is the increasing demand from the steel industry. Extruded graphite is widely used in electric arc furnaces for steel production, where it serves as an essential material for the electrodes that conduct electricity and generate heat to melt scrap steel. With the growing demand for steel in construction, automotive, and infrastructure development, the demand for extruded graphite is expected to increase significantly.Moreover, the electronics industry is another major consumer of extruded graphite. The material is used in the manufacturing of EDM (electrical discharge machining) electrodes, which are essential for creating precise and complex shapes in metal parts. As industries such as aerospace, automotive, and medical devices continue to demand high-precision components, the demand for extruded graphite in EDM applications is expected to grow.Additionally, extruded graphite is also used in the manufacturing of crucibles for the melting and casting of non-ferrous metals such as aluminum, copper, and zinc. With the increasing demand for these metals in various industries, the market for extruded graphite crucibles is expected to witness steady growth.The global extruded graphite market is highly competitive, with several key players competing for market share. {Company name}, a leading manufacturer of extruded graphite products, has established itself as a key player in the market through its focus on product innovation, quality, and customer service.The company's extruded graphite products are known for their superior performance and reliability, making them the material of choice for various industrial applications. With a strong emphasis on research and development, {Company name} continues to introduce new and improved extruded graphite materials that meet the evolving needs of its customers.Moreover, {Company name} is committed to sustainability and environmental responsibility in its manufacturing processes. The company's extruded graphite products are manufactured using high-quality raw materials and state-of-the-art production techniques, ensuring minimal environmental impact.In addition to its focus on product quality and sustainability, {Company name} is also known for its exceptional customer service and technical support. The company works closely with its customers to understand their specific needs and offer tailored solutions that meet their requirements, whether it be for steel production, EDM machining, or other applications.Looking ahead, the future of the extruded graphite market looks promising, with growing demand from key industries and ongoing innovation in materials and manufacturing processes. As a leading player in the market, {Company name} is well positioned to capitalize on these opportunities and continue its growth trajectory in the coming years.In summary, the global extruded graphite market is expected to see significant growth in the coming years, driven by increasing demand from the steel, electronics, and non-ferrous metal industries. With its focus on product innovation, quality, and customer service, {Company name} is poised to play a key role in shaping the future of the extruded graphite market.

Important Factors for Graphite Purity in Manufacturing

Graphite Purity is a leading company in the graphite industry, specializing in the production and supply of high-quality graphite materials. With a commitment to excellence and innovation, Graphite Purity has established itself as a reliable partner for businesses across various sectors, including aerospace, automotive, energy, and electronics.The company's dedication to quality is evident in its strict adherence to international standards and its continuous investment in advanced technologies and research. This commitment has enabled Graphite Purity to consistently deliver products that meet and exceed the expectations of its customers, allowing them to achieve their manufacturing and production goals with precision and efficiency.One of the key factors that set Graphite Purity apart from its competitors is its focus on graphite purity. The company recognizes the importance of purity in graphite materials, as it directly impacts the performance and quality of the end products in which the graphite is used. As a result, it has implemented rigorous processes and quality control measures to ensure that its graphite materials are of the highest purity levels.Graphite Purity's dedication to purity is reflected in its manufacturing facilities, where state-of-the-art equipment and technologies are employed to produce graphite materials with exceptional purity levels. The company's team of experienced professionals oversees the entire production process, from raw material sourcing to final product inspection, to guarantee that only the highest quality graphite materials leave its facilities.In addition to its commitment to purity, Graphite Purity places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, minimizing its carbon footprint and reducing waste generation. Furthermore, its graphite materials are produced in compliance with stringent environmental regulations, ensuring that they are not only of superior quality but also environmentally friendly.Graphite Purity's dedication to excellence, purity, and sustainability has earned it a solid reputation in the graphite industry. Its products are recognized for their exceptional quality and performance, making the company a preferred supplier for businesses seeking reliable and high-quality graphite materials. Whether it's for creating lightweight yet durable components for aerospace applications or developing high-performance batteries for electric vehicles, Graphite Purity's materials play a crucial role in driving innovation and progress across various industries.As the demand for high-quality graphite materials continues to grow, Graphite Purity remains committed to meeting the needs of its customers. The company continually invests in research and development to enhance its product offerings and expand its portfolio to cater to evolving industry requirements. By staying at the forefront of technological advancements and industry trends, Graphite Purity is well-positioned to address the evolving needs of its customers and maintain its status as a leader in the graphite industry.In conclusion, Graphite Purity's unwavering commitment to excellence, purity, and sustainability sets it apart as a reliable partner for businesses in need of high-quality graphite materials. With a focus on quality, innovation, and customer satisfaction, the company is poised to continue its success and make a meaningful impact in the graphite industry for years to come.

High Quality Graphite Sheet and Gasket from China

Graphite Sheet and Graphite Gasket are the two crucial components in many industrial applications. These materials are known for their excellent thermal conductivity, chemical resistance, and electrical conductivity. They are widely used in various industries such as automotive, aerospace, electronics, and manufacturing.One of the leading manufacturers of Graphite Sheet and Graphite Gasket is {Company Name}. With years of experience and expertise in the industry, {Company Name} has established itself as a trusted supplier of high-quality graphite products.Graphite Sheet, also known as graphite foil, is a flexible graphite material made from high purity natural graphite flakes. It is typically used for gasket and sealing applications in various industries. Graphite Gaskets, on the other hand, are designed to provide a reliable seal for high-temperature and high-pressure applications. They are commonly used in engines, compressors, and other industrial equipment.{Company Name} has a comprehensive range of graphite products including flexible graphite sheets, graphite gaskets, and custom-made graphite parts. The company's products are manufactured using state-of-the-art technology and strict quality control measures to ensure superior performance and reliability.In a recent development, {Company Name} has introduced a new line of Graphite Sheet and Graphite Gasket products to meet the growing demand in the global market. These new products are specially designed to offer enhanced thermal conductivity, improved chemical resistance, and excellent sealing properties.The Graphite Sheet and Graphite Gasket products from {Company Name} are ideal for a wide range of applications including heat exchangers, gaskets, seals, and insulation. They are capable of withstanding extreme temperatures and harsh chemical environments, making them suitable for use in demanding industrial settings.{Company Name} is committed to providing high-quality graphite products that meet the stringent requirements of its customers. The company's team of experts continuously strives to innovate and develop new solutions to address the evolving needs of the industry.In addition to its standard product offerings, {Company Name} also provides custom solutions to meet specific customer requirements. The company's engineering team works closely with clients to design and manufacture tailor-made graphite products that perfectly fit their applications.With a focus on quality, reliability, and customer satisfaction, {Company Name} has built a strong reputation in the graphite industry. The company's products are known for their exceptional performance, durability, and cost-effectiveness.{Company Name} aims to expand its presence in the global market and serve a wider customer base with its premium quality Graphite Sheet and Graphite Gasket products. The company is dedicated to maintaining its position as a leading supplier of graphite solutions and contributing to the advancement of various industries.As the demand for Graphite Sheet and Graphite Gasket continues to rise, {Company Name} remains at the forefront of providing innovative and reliable products that meet the requirements of the modern industrial landscape. With its unwavering commitment to excellence, the company is poised to solidify its position as a trusted partner for businesses seeking high-quality graphite solutions.

Latest Developments in the Revolutionary Crucible Technology Unveiled

Forging a Crucible: Revolutionizing the Industry with Advanced TechnologyIn today's rapidly evolving world, technology is at the forefront of every innovation. Forging is no exception. With the introduction of advanced machinery and cutting-edge techniques, traditional forging methods have undergone a significant transformation. One company at the forefront of this technological revolution is Forge Crucible, a global leader in the industry. Let us explore how Forge Crucible has revolutionized the world of forging through their innovative solutions and commitment to excellence.Forge Crucible, a pioneer in the field, combines years of expertise with state-of-the-art technology to deliver unmatched products and services. With a rich heritage dating back to 1965, the company has consistently strived to push the boundaries of what is possible in the forging industry. Their dedication to continual improvement and invention has earned them a sterling reputation as a reliable, innovative, and customer-centric organization.At the heart of Forge Crucible's success lies their relentless pursuit of technological advancements. The company embraces automation, robotics, and advanced digitalization techniques to enhance productivity, quality, and efficiency. By investing heavily in Research and Development (R&D), they consistently stay ahead of the curve, setting new industry standards.One of Forge Crucible's landmark technological advancements is their proprietary "IntelliForge" system. This cutting-edge technology combines artificial intelligence (AI) with sophisticated sensors and monitoring tools to optimize forging processes. The IntelliForge system analyzes real-time data, identifying inefficiencies and making instantaneous adjustments to ensure optimal productivity and product quality. By harnessing the power of AI, Forge Crucible has revolutionized the forging process, reducing downtime, enhancing output, and reducing waste.Furthermore, Forge Crucible understands that agility and versatility are key in today's highly competitive market. Their advanced forging machinery is equipped with quick-change capabilities, allowing for rapid adaptation to meet diverse customer requirements. This flexibility has earned Forge Crucible a reputation for being an industry leader in customized forging solutions.In addition to technological advancements, Forge Crucible places a premium on sustainable and environmentally friendly practices. The company has implemented efficient energy management systems and stringent waste management protocols, minimizing their ecological footprint. By prioritizing sustainability, Forge Crucible showcases their commitment to responsible corporate citizenship.Forge Crucible's customer-centric approach is another key factor in their success. Recognizing that no two customers are alike, they offer tailor-made solutions and a dedicated team of experts to guide clients through every stage of the forging process. Forge Crucible's commitment to outstanding customer service has earned them a loyal and ever-expanding client base, transcending geographical boundaries.Notable projects completed by Forge Crucible serve as a testament to their excellence and ability to tackle complex challenges. Whether it is forging critical components for the aerospace industry or high-performance parts for the automotive sector, Forge Crucible consistently delivers superior quality products that meet stringent industry standards.Looking to the future, Forge Crucible is committed to pioneering innovative technologies and processes. Their ongoing collaboration with academic institutions and industry partners ensures they are always on the cutting edge. The company aims to explore new materials, further automation, and develop sustainable forging techniques, thereby shaping the future of the industry.In conclusion, Forge Crucible's unwavering commitment to innovation, technological advancement, and customer satisfaction has propelled them to the top of the forging industry. By combining state-of-the-art technology with years of expertise, they have revolutionized the forging process. Through their proprietary systems, commitment to sustainability, and customer-centric approach, Forge Crucible continues to set new benchmarks in the industry. As they forge ahead, the world of forging can expect even greater advancements, thanks to companies like Forge Crucible leading the way.

High-performance Crucible Furnace for Silver Melting

Silver Crucible Furnace, a leading player in the field of industrial furnaces and heat treatment equipment, has recently introduced a new and innovative solution for the production of high-quality silver products. This new furnace is set to revolutionize the silver processing industry with its cutting-edge technology and advanced features.The new furnace, designed and manufactured by Silver Crucible Furnace, is specifically tailored for the production of silver products such as ingots, bars, and coins. With its high temperature capabilities and precise control system, the furnace ensures the production of silver products with superior quality and consistency.The furnace is equipped with state-of-the-art technology that enables efficient and precise heating and melting of silver materials. It also comes with advanced safety features and an intuitive control interface for ease of operation. This makes it an ideal solution for silver refineries, mints, and other facilities involved in the production of silver products.Silver Crucible Furnace has a solid reputation in the industry for providing reliable and high-performance furnaces for various industrial applications. With over 20 years of experience, the company has consistently delivered innovative solutions that meet the evolving needs of its customers.The company's commitment to quality and customer satisfaction is evident in the design and engineering of the new silver crucible furnace. By leveraging its expertise and technological capabilities, Silver Crucible Furnace has developed a solution that is set to raise the standard for silver production processes.In addition to its technical capabilities, the new furnace also reflects Silver Crucible Furnace's dedication to environmental sustainability. The furnace is designed to optimize energy efficiency and minimize emissions, aligning with the company's commitment to eco-friendly solutions for industrial applications."We are excited to introduce our latest innovation in silver processing technology," said the CEO of Silver Crucible Furnace. "The new furnace is a testament to our dedication to pushing the boundaries of innovation and meeting the needs of our customers. We believe that this new solution will set a new benchmark for efficiency, quality, and sustainability in the production of silver products."The introduction of the new silver crucible furnace is expected to have a significant impact on the silver production industry, offering a reliable and advanced solution for companies looking to enhance their manufacturing processes. With its cutting-edge technology, precision control, and environmental considerations, the furnace is poised to streamline operations and drive efficiency for silver refineries and mints.As Silver Crucible Furnace continues to innovate and set new industry standards, the company remains committed to providing top-quality solutions for industrial heating and melting processes. Its dedication to excellence, combined with a focus on sustainability and customer satisfaction, positions Silver Crucible Furnace as a trusted partner for companies seeking reliable and innovative furnace solutions.In conclusion, the introduction of the new silver crucible furnace by Silver Crucible Furnace marks a significant milestone in the silver production industry. With its advanced technology, precision control, and environmental considerations, the furnace is set to revolutionize the production of high-quality silver products. As the company continues to push the boundaries of innovation and excellence, it reaffirms its position as a leading player in the field of industrial furnaces and heat treatment equipment.

Durable Graphite Lined Crucible for Industrial Use

Introducing the New Graphite Lined Crucible: Revolutionizing Metal CastingMetal casting is a crucial process in various industries, including automotive, aerospace, and manufacturing. The quality of the casted metal products is highly dependent on the tools and equipment used in the casting process. Crucibles play a vital role in metal casting as they hold the molten metal before it is poured into the molds. To ensure the highest quality of casted products, it is essential to use premium quality crucibles that can withstand the extreme temperature and thermal shock during the casting process.In recent news, a leading company in the field of metallurgy and material science has introduced a revolutionary product in the realm of metal casting - the Graphite Lined Crucible. The company, with its decades of experience and expertise in producing high-quality materials for industrial applications, has developed this advanced crucible to address the challenges and demands of modern metal casting processes.The Graphite Lined Crucible is designed to offer exceptional performance and durability in high-temperature environments. It is made from high-purity graphite material, known for its excellent thermal conductivity, high-temperature resistance, and superior strength. The crucible is lined with graphite to enhance its performance and prolong its lifespan, making it an ideal choice for handling molten metals in various casting applications.One of the key features of the Graphite Lined Crucible is its ability to withstand thermal shock, a common occurrence in metal casting processes. The rapid temperature changes during the casting process can cause traditional crucibles to crack or fail, leading to product defects and increased downtime. With its superior thermal shock resistance, the Graphite Lined Crucible ensures a more stable and reliable casting process, resulting in higher yield and improved product quality.Furthermore, the unique design of the Graphite Lined Crucible promotes uniform heat distribution, ensuring that the molten metal is heated evenly and consistently. This is essential for producing high-quality casted products with precise dimensions and properties. The crucible's graphite lining also minimizes metal contamination, contributing to cleaner and more refined casted products.In addition to its exceptional performance, the Graphite Lined Crucible is also designed for ease of use and maintenance. Its lightweight construction and ergonomic design make it easy to handle and install, reducing the risk of workplace injuries and fatigue. Moreover, the graphite lining minimizes the buildup of slag and impurities, simplifying the cleaning and maintenance process.The introduction of the Graphite Lined Crucible marks a significant advancement in the field of metal casting technology. Its innovative design and superior performance set a new standard for crucibles in the industry, offering manufacturers a reliable and cost-effective solution for their casting needs. With its potential to improve product quality, increase operational efficiency, and reduce downtime, the Graphite Lined Crucible is poised to become an indispensable tool for metal casting operations across various industries.As a company committed to innovation and excellence, we are proud to bring this cutting-edge product to the market. Our Graphite Lined Crucible reflects our dedication to meeting the evolving needs of the industry and our customers. We believe that this advanced crucible will empower manufacturers to elevate their metal casting processes and deliver exceptional results.In conclusion, the introduction of the Graphite Lined Crucible represents a significant milestone in the advancement of metal casting technology. Its exceptional performance, durability, and ease of use make it a game-changer for the industry. As manufacturers strive for higher quality and efficiency in their casting processes, the Graphite Lined Crucible stands out as a reliable and innovative solution. We are excited to see the positive impact that this revolutionary crucible will have on the industry and look forward to supporting our customers in adopting this cutting-edge technology.

High-Quality 50ml Silica Crucible at Competitive Price

Silica Crucible 50ml Price Sees Major Decrease in the MarketSilica crucibles are an essential tool in various industries, including chemical, medical, and research sectors. These crucibles are widely used for heating, melting, and analyzing various substances due to their high-temperature resistance and inert properties. With the increasing demand for high-quality silica crucibles, the market has seen a significant shift in prices in recent months.The price of a 50ml silica crucible has seen a major decrease in the market, much to the benefit of consumers and businesses alike. This decrease in price can be attributed to the introduction of a new and innovative manufacturing process by a well-known company in the industry.The company, which has been a leading manufacturer of silica crucibles for over 20 years, has recently implemented a state-of-the-art manufacturing process that has allowed them to produce high-quality silica crucibles at a lower cost. This has directly impacted the market price of these crucibles, making them more affordable for a wide range of businesses and research facilities.The new manufacturing process not only reduced production costs but also improved the overall quality and durability of the silica crucibles. This has been a game-changer in the industry, as businesses can now access top-of-the-line crucibles at a fraction of the previous cost.In addition to the cost benefits, the company has also introduced a wide range of customization options for their silica crucibles. Customers can now choose from various sizes, shapes, and specifications to meet their specific needs. This level of customization was previously unheard of in the industry and has been well-received by businesses and researchers who require specialized crucibles for their applications.The decrease in price and the introduction of customization options have sparked a significant increase in demand for silica crucibles in the market. Businesses that were previously unable to afford high-quality crucibles can now invest in these essential tools without compromising on quality.Furthermore, the company's commitment to sustainability and environmental responsibility has also impacted the market. The new manufacturing process has significantly reduced the environmental impact of producing silica crucibles, making them a more eco-friendly option for businesses.The decrease in price and the improved quality of silica crucibles have created a ripple effect in the market. Other manufacturers are now under pressure to match these new standards, leading to a healthier and more competitive market for silica crucibles.In response to the market shift, many businesses and research facilities have already made the switch to the new and improved silica crucibles. The cost savings and enhanced performance of these crucibles have proven to be a significant advantage for those who rely on them for their day-to-day operations.Overall, the decrease in the price of 50ml silica crucibles has been a game-changer in the industry. With the implementation of a new manufacturing process and a focus on sustainability, the market has seen a significant shift in prices and quality. Businesses and researchers can now access high-quality, customized silica crucibles at a fraction of the previous cost, making them a more accessible and practical option for various applications. As the demand for these crucibles continues to rise, it is clear that the market will be forever changed by this innovative approach to manufacturing.

Highly Efficient Metal Melting Furnace for Industrial Use

Metal Melting Furnace Revolutionizes Industrial ManufacturingThe industrial manufacturing sector is constantly evolving, seeking innovative solutions to improve efficiency, reduce costs, and enhance production capabilities. One of the key components in this pursuit is the metal melting furnace, a critical tool for the processing and shaping of various metals. Recently, {Company name}, a leading provider of industrial equipment and machinery, has introduced a state-of-the-art metal melting furnace that is set to revolutionize the industry.With decades of experience in the manufacturing and engineering industry, {Company name} has established itself as a trusted and reliable source for cutting-edge equipment. The company's commitment to innovation and quality has led to the development of the new metal melting furnace, which boasts advanced features and unparalleled performance.The new metal melting furnace, designed and manufactured by {Company name}, is a game-changer for industrial manufacturing processes. Equipped with the latest technology, the furnace offers precise temperature control, efficient energy consumption, and the capacity to melt a wide range of metals, including steel, aluminum, copper, and more. This versatility makes it an invaluable asset for various applications across different industries, from automotive and aerospace to construction and electronics.Furthermore, the furnace is engineered for durability and longevity, ensuring reliable operation in demanding industrial environments. Its robust construction and high-quality components contribute to minimal maintenance requirements and extended service life, offering a cost-effective solution for manufacturing facilities.In addition to its exceptional performance, the metal melting furnace from {Company name} also prioritizes safety and environmental responsibility. The furnace is designed with advanced safety features to protect operators and workers, while also incorporating energy-efficient technology to minimize its environmental impact. This aligns with {Company name}'s commitment to sustainability and corporate social responsibility, ensuring that its products contribute to a greener and more sustainable future.The introduction of this cutting-edge metal melting furnace underscores {Company name}'s dedication to meeting the evolving needs of the industrial manufacturing sector. By leveraging its expertise and resources, the company has delivered a solution that can enhance productivity, quality, and cost-efficiency for businesses across various industries.{Company name} has also invested in comprehensive customer support services to accompany the metal melting furnace, offering technical assistance, training, and maintenance to ensure optimal performance and reliability. This commitment to customer satisfaction further distinguishes {Company name} as a leader in the industrial equipment market.Companies that have already adopted the metal melting furnace from {Company name} have reported significant improvements in their manufacturing processes. The furnace's ability to achieve precise and consistent melting temperatures has resulted in higher-quality metal products and reduced material waste. Additionally, its energy-efficient design has led to cost savings and a smaller carbon footprint, aligning with the growing emphasis on sustainability in the manufacturing industry.As the global industrial landscape continues to evolve, the demand for advanced equipment and machinery remains strong. The new metal melting furnace from {Company name} represents a significant advancement in the industry, providing a reliable, efficient, and sustainable solution for metal processing and manufacturing. Its introduction is set to have a transformative impact on industrial operations, driving productivity and innovation for years to come.

High-efficiency Oil Fired Crucible Furnace for Industrial Use

Oil Fired Crucible Furnace is a crucial piece of equipment in the metal casting and foundry industry. This furnace is used to melt and pour metals like bronze, brass, aluminum, and iron into molds to create various industrial and consumer products. The furnace is a significant part of the manufacturing process and plays a vital role in the production of a wide range of metal products.{Company Name} is a leading manufacturer of Oil Fired Crucible Furnaces, with a strong presence in the global market. The company has a rich history in the field of industrial furnaces and has been providing high-quality equipment to its customers for many years. As a reputed supplier, the company is known for its innovative technologies, reliable products, and excellent customer service.The Oil Fired Crucible Furnace offered by {Company Name} is a highly efficient and reliable piece of equipment that is designed to meet the diverse needs of the metal casting industry. The furnace is equipped with advanced features and is built to withstand the high temperatures and rigorous demands of the metal casting process. It is a critical component in the production of various metal products and is widely used in foundries, metal workshops, and industrial manufacturing plants.The {Company Name} Oil Fired Crucible Furnace is designed to provide precise temperature control and uniform heating, ensuring that the molten metal reaches the desired consistency and quality. This level of control is essential in producing high-quality metal products that meet industry standards and customer requirements. The furnace is also designed with safety features to protect workers and prevent accidents in the workplace.In addition to its technical capabilities, the {Company Name} Oil Fired Crucible Furnace is also known for its energy efficiency and low operating costs. The furnace is designed to optimize fuel consumption and reduce waste, making it a cost-effective solution for businesses in the metal casting industry. This not only helps to lower production costs but also contributes to environmental sustainability by reducing the overall carbon footprint of the manufacturing process.Furthermore, {Company Name} provides comprehensive support and maintenance services for its Oil Fired Crucible Furnace, ensuring that customers can maximize the performance and longevity of their equipment. The company has a dedicated team of experts who are available to provide technical assistance, conduct regular maintenance, and address any issues that may arise with the furnace. This level of support is crucial for businesses that rely on their equipment to maintain a smooth and efficient production process.With a strong commitment to quality, innovation, and customer satisfaction, {Company Name} continues to be a preferred choice for businesses in the metal casting and foundry industry. The company's Oil Fired Crucible Furnace is trusted by manufacturers around the world for its reliability, performance, and efficiency. {Company Name} remains at the forefront of the industry, continually striving to develop new technologies and solutions that meet the evolving needs of its customers and the industry as a whole.In conclusion, the Oil Fired Crucible Furnace is a critical piece of equipment in the metal casting and foundry industry, and {Company Name} is a leading manufacturer of this essential equipment. With its advanced features, energy efficiency, and commitment to customer support, the company continues to be a trusted partner for businesses seeking reliable and high-quality furnace solutions. As the metal casting industry continues to grow and evolve, {Company Name} remains dedicated to providing innovative and dependable equipment that helps its customers succeed in their production endeavors.