- Home

- Blog

- High-Quality Holding Furnace for Aluminum Processing: Essential Equipment for Aluminum Production

High-Quality Holding Furnace for Aluminum Processing: Essential Equipment for Aluminum Production

By:Admin

Aluminium is a versatile and crucial material in various industries, from automotive to construction. The process of manufacturing aluminium involves several steps, one of which is the use of holding furnaces to maintain the molten aluminium at an optimal temperature for further processing. One company that has been at the forefront of providing innovative holding furnace solutions for the aluminium industry is {}.

{} is a renowned industry leader in providing advanced engineering solutions for the aluminium industry. With a strong focus on research and development, the company has been consistently delivering cutting-edge technologies and products to enhance the efficiency and quality of aluminium production processes.

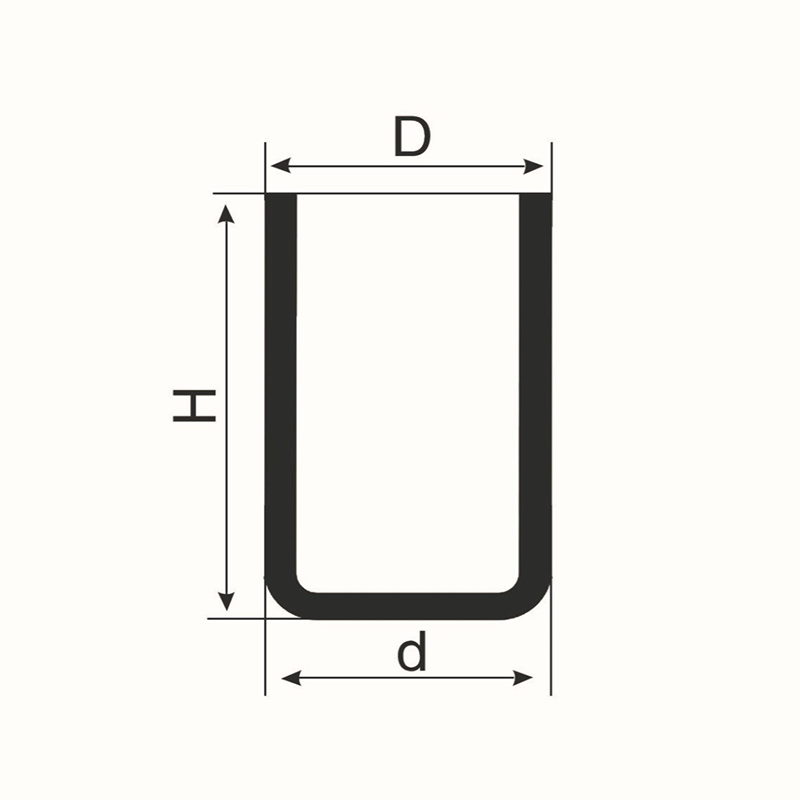

The holding furnace is a critical component in the aluminium production process, as it allows the molten aluminium to be kept at a specific temperature, ensuring it remains in its liquid state and ready for further processing. {}'s holding furnaces are designed with precision engineering and advanced thermal control systems to ensure the consistent and reliable performance required for the demanding aluminium industry.

The company's holding furnaces are equipped with state-of-the-art temperature monitoring and control systems, allowing for precise adjustments and ensuring optimal thermal stability. This level of control is crucial in maintaining the quality of the molten aluminium, which directly impacts the final product's quality and performance.

In addition to the advanced technological features, {}'s holding furnaces are also designed with a strong emphasis on energy efficiency and environmental sustainability. The company understands the importance of minimizing energy consumption and reducing environmental impact in the manufacturing process. As a result, their holding furnaces are engineered to maximize energy efficiency while minimizing emissions, aligning with the industry's growing focus on sustainability.

Furthermore, {}'s holding furnace solutions are tailored to meet the specific needs and requirements of each client. Whether it's a small-scale operation or a large production facility, the company's team of experts works closely with clients to design and implement customized holding furnace solutions that optimize productivity and performance.

With a strong commitment to innovation and customer satisfaction, {} has positioned itself as a trusted partner for aluminium producers worldwide. The company's extensive portfolio of holding furnace solutions has earned it a reputation for reliability, performance, and technological advancement.

In conclusion, the aluminium industry relies heavily on advanced engineering solutions to maintain the highest standards of quality and efficiency in the production process. {}'s holding furnace solutions exemplify the company's dedication to delivering cutting-edge technologies that enable aluminium producers to achieve superior results. With a focus on precision engineering, energy efficiency, and environmental sustainability, {} continues to be a driving force in shaping the future of the aluminium industry.

Company News & Blog

High-Quality Graphite Crucible for Purity Applications

Purity Graphite CruciblePurity graphite crucibles are an essential component in the production of metal alloys and other high-temperature materials. The company {} is a leading manufacturer of graphite crucibles, known for their high purity and exceptional performance in various industrial applications.{} has been in the business of producing graphite crucibles for over a decade. The company prides itself on its commitment to quality, innovation, and customer satisfaction. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, {} has been able to establish itself as a reliable and trusted supplier of graphite crucibles in the global market.The purity graphite crucibles offered by {} are made from high-quality graphite material, which provides excellent thermal conductivity and high-temperature resistance. These crucibles are designed to withstand extreme heat and harsh chemical environments, making them suitable for use in a wide range of applications, including metal casting, melting, and refining processes.One of the key features of {}'s purity graphite crucibles is their exceptional purity levels, which ensure minimal impurities and contamination in the materials being processed. This is crucial for industries that require precise and high-quality output, such as aerospace, automotive, and electronics manufacturing.Another important aspect of {}'s graphite crucibles is their durability and longevity. These crucibles are engineered to withstand repeated thermal cycling and thermal shock, ensuring a long and reliable service life. This is particularly beneficial for industrial operations that require continuous and uninterrupted production.In addition to their superior performance, {}'s purity graphite crucibles are also designed to be environmentally friendly. The company adheres to strict environmental standards in the manufacturing process, ensuring that their products have minimal impact on the environment.Furthermore, {} offers a wide range of graphite crucible sizes and designs to meet the specific needs of different industries and applications. This customization capability sets the company apart from its competitors, allowing customers to find the perfect crucible solution for their unique requirements.To ensure the highest quality and consistency, {} employs strict quality control measures throughout the production process. Every graphite crucible undergoes rigorous testing and inspection to guarantee its performance and reliability.As a customer-centric company, {} is dedicated to providing exceptional customer service and support. The company's team of knowledgeable professionals is available to assist customers with product selection, technical information, and any other inquiries they may have.In conclusion, {}'s purity graphite crucibles are the ideal choice for industries that demand high-performance, reliability, and precision in their thermal processing operations. With a proven track record of excellence and a commitment to innovation, {} continues to be a trusted partner for companies seeking the best graphite crucible solutions.For more information about {} and their purity graphite crucibles, please visit their website or contact their sales team directly.Contact Information:Website: {}Email: [email protected]Phone: +xxx-xxx-xxxx

Top Quality Graphite Electrode for Edm Machining: All You Need to Know

Edm Graphite Electrode: A Key Component for Cutting-Edge TechnologyIn today's fast-paced and innovative world, technology is constantly evolving, and companies are constantly seeking to push the boundaries of what is possible. One crucial component that is driving these advancements is the Edm Graphite Electrode. This advanced technology has enabled manufacturers to achieve new levels of precision, efficiency, and performance in their production processes.Developed and manufactured by a leading company in the industry, Edm Graphite Electrode has become a key player in the field of EDM (Electrical Discharge Machining). The company has a long-standing reputation for producing high-quality and reliable products, and their Edm Graphite Electrode is no exception. With its exceptional durability, conductivity, and performance, it has become an essential tool for industries such as aerospace, automotive, medical, and electronics.The use of Edm Graphite Electrode has revolutionized the way manufacturers approach precision machining and tooling. Its ability to precisely shape and cut through tough materials such as hardened steel, titanium, and exotic alloys has made it a game-changer in the industry. This technology has allowed companies to push the boundaries of what is possible in terms of design complexity and accuracy, leading to the production of innovative and high-performance products.Furthermore, the company behind Edm Graphite Electrode has a strong commitment to sustainability and environmental responsibility. Their products are manufactured using environmentally friendly processes and materials, and they are continuously working towards reducing their carbon footprint. This dedication to sustainability has made them a preferred supplier for companies that prioritize eco-friendly practices in their operations.In addition to its outstanding performance and environmental benefits, Edm Graphite Electrode has also proven to be a cost-effective solution for manufacturers. Its long lifespan and minimal maintenance requirements have resulted in significant cost savings for companies, making it a highly attractive investment for businesses of all sizes.The company's dedication to innovation and continuous improvement has also led to the development of new and advanced versions of Edm Graphite Electrode. Their team of experts is constantly researching and refining their products to ensure that they meet the ever-changing needs of the industry. This commitment to staying ahead of the curve has solidified their position as a leader in the field of EDM technology.As the demand for high-precision manufacturing continues to grow, the importance of Edm Graphite Electrode will only increase. Its ability to deliver unparalleled accuracy, efficiency, and reliability has made it an indispensable tool for companies seeking to stay ahead in today's competitive market.In conclusion, the Edm Graphite Electrode, developed and manufactured by a reputable company, has become an essential technology for industries that require high-precision machining. Its exceptional performance, sustainability, and cost-effectiveness have made it a preferred choice for manufacturers seeking to push the boundaries of what is possible in their production processes. As technology continues to advance, Edm Graphite Electrode will undoubtedly play a crucial role in driving innovation and progress in the manufacturing industry.

High-quality Crucible For Casting: A Guide to Choosing the Best Option

Crucible For Casting (Need remove brand name), a leading manufacturer of high-quality crucibles for metal casting, has a long history of providing top-notch products to the foundry industry. With a commitment to excellence and innovation, the company has built a strong reputation for delivering reliable and efficient crucibles to its customers.Established in [year], Crucible For Casting has continually pushed the boundaries of crucible technology to meet the ever-evolving needs of the metal casting industry. With a focus on research and development, the company has developed a wide range of crucibles that are specifically designed to withstand the rigors of high-temperature environments and to provide consistent and reliable performance.One of the key strengths of Crucible For Casting is its dedicated team of engineers and technicians who are constantly striving to improve the performance and durability of their crucibles. Through rigorous testing and quality control measures, the company ensures that each crucible that leaves its facility meets the highest standards of quality and reliability.In addition to its commitment to product excellence, Crucible For Casting also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific casting requirements and to develop custom solutions that meet their unique needs. This customer-centric approach has earned Crucible For Casting a loyal and satisfied customer base that continues to rely on the company for all of their crucible needs.Crucible For Casting's dedication to excellence and innovation was recently highlighted in a groundbreaking new development in crucible technology. The company announced the launch of a new line of advanced crucibles that are designed to offer improved thermal shock resistance and longer service life. This development is a testament to Crucible For Casting's commitment to pushing the boundaries of what is possible in the field of crucible technology.Commenting on the new product launch, [Spokesperson Name], a representative from Crucible For Casting, stated, "We are thrilled to introduce our latest line of advanced crucibles to the market. These new crucibles represent a significant leap forward in terms of performance and durability, and we are confident that they will set a new industry standard for excellence. We believe that these crucibles will provide our customers with a competitive edge in their casting operations and help them achieve greater levels of efficiency and reliability."The new line of advanced crucibles from Crucible For Casting has already generated a great deal of excitement within the industry, with many foundries expressing strong interest in adopting the new technology. With its proven track record of delivering high-quality products and its commitment to innovation, Crucible For Casting is well-positioned to maintain its leadership position in the crucible manufacturing industry.As Crucible For Casting continues to push the boundaries of crucible technology, the company remains focused on its core values of excellence, innovation, and customer satisfaction. With a strong foundation built on decades of experience and a dedicated team of professionals, Crucible For Casting is poised to continue providing the foundry industry with the highest quality crucibles for years to come.In conclusion, Crucible For Casting is a company that has consistently demonstrated its commitment to excellence and innovation in the field of crucible manufacturing. With a focus on research and development, a customer-centric approach, and a track record of delivering high-quality products, the company is well-positioned to continue leading the industry and meeting the evolving needs of the foundry industry.

High-Temperature Crucible Reaches 3000 Degrees in Breakthrough Experiment

3000 Degree Crucible, a leading manufacturer of high-temperature industrial materials, has recently announced a new breakthrough in their product line. The company, known for its innovative and high-quality products, has developed a new material that can withstand temperatures of up to 3000 degrees Celsius, making it ideal for a wide range of industrial applications.The new material, which has been in development for several years, is a result of the company's commitment to innovation and continuous improvement. It is designed to meet the growing demand for materials that can withstand extreme temperatures in industries such as aerospace, automotive, and energy production.With this new product, 3000 Degree Crucible aims to provide its customers with a reliable and versatile material that can be used in a variety of high-temperature applications. The company's dedication to research and development has enabled them to create a material that is not only highly durable but also cost-effective, making it an attractive option for industries looking to improve their processes and products.In addition to its exceptional thermal properties, the new material is also resistant to corrosion and chemical degradation, further enhancing its suitability for a wide range of industrial applications. This makes it an ideal choice for companies looking to improve the performance and longevity of their products in high-temperature environments.3000 Degree Crucible has built a strong reputation for delivering high-quality, reliable products to its customers, and this new material is a testament to the company's commitment to excellence. With a focus on customer satisfaction and continuous improvement, the company is dedicated to providing the best possible solutions to meet the evolving needs of the industrial market.The development of this new material highlights 3000 Degree Crucible's position as a leader in the industry, and underscores their dedication to pushing the boundaries of what is possible in high-temperature materials. By continuously investing in research and development, the company aims to stay ahead of the competition and deliver innovative solutions that meet the ever-changing demands of the market.In addition to its commitment to product development, 3000 Degree Crucible also places a strong emphasis on sustainability and environmental responsibility. The company's manufacturing processes are designed to minimize waste and reduce environmental impact, reflecting their dedication to creating a more sustainable future for the industry.With the introduction of this new high-temperature material, 3000 Degree Crucible is poised to further solidify its position as a leading provider of industrial materials. The company's unwavering commitment to innovation, quality, and customer satisfaction sets them apart in the industry, and their latest breakthrough is a testament to their dedication to pushing the boundaries of what is possible in high-temperature materials.In conclusion, 3000 Degree Crucible's new high-temperature material is set to revolutionize the industrial market, providing companies with a reliable and versatile solution for their high-temperature applications. With a focus on innovation, quality, and customer satisfaction, the company continues to lead the way in developing cutting-edge materials that meet the evolving needs of the industry.

High-Quality Aluminium Crucible Melting Furnace for Efficient Metal Melting

Aluminium Crucible Melting Furnace Enhances Company's Production CapabilitiesAs a leading manufacturer in the [industry], we are constantly looking for innovative ways to improve our production process and deliver high-quality products to our customers. To this end, we are excited to announce the installation of a new Aluminium Crucible Melting Furnace, which is set to revolutionize our manufacturing capabilities.The new Aluminium Crucible Melting Furnace is a state-of-the-art piece of equipment that will allow us to streamline our production process and significantly increase our output. This furnace is designed to efficiently and precisely melt and alloy aluminum, allowing for the production of a wide range of high-quality aluminum products. With its advanced technology and automation features, the furnace will enable us to achieve greater precision and consistency in our manufacturing process, ensuring that our products meet the highest standards of quality and performance.One of the key benefits of the new Aluminium Crucible Melting Furnace is its ability to handle a wide range of aluminum alloys, including those with high melting points and specific metallurgical requirements. This versatility will enable us to expand our product offering and meet the diverse needs of our customers. Additionally, the furnace is equipped with advanced temperature control systems and energy-efficient heating elements, which will not only reduce our energy consumption and operating costs but also minimize our environmental footprint.In addition to its technical capabilities, the new furnace is also designed with worker safety and ease of operation in mind. It is equipped with advanced safety features and automation controls, which will ensure the well-being of our employees and optimize the overall efficiency of our manufacturing operations. Furthermore, its user-friendly interface and intuitive controls will allow our operators to easily monitor and adjust the furnace settings, maximizing productivity and minimizing downtime.The installation of the Aluminium Crucible Melting Furnace represents a significant investment in our manufacturing infrastructure and underscores our commitment to delivering superior products and services to our customers. By incorporating this advanced technology into our operations, we are confident that we will be able to further enhance our competitive position in the market and meet the growing demand for high-quality aluminum products.Furthermore, this investment in new technology reflects our long-term strategy to continuously improve and innovate our manufacturing processes. We believe that by staying at the forefront of technological advancements, we will be able to adapt to changing market dynamics and stay ahead of the competition. This, in turn, will enable us to better serve our customers and drive the continued success and growth of our business.In conclusion, the installation of the new Aluminium Crucible Melting Furnace marks a significant milestone in our company's journey towards excellence in manufacturing. With its cutting-edge technology and capabilities, we are confident that it will have a transformative impact on our production capabilities, enabling us to deliver even greater value to our customers and partners. We are excited about the potential of this new furnace and look forward to the opportunities it will unlock for our business and the industry as a whole.

Innovative Metal Melting Machine: A Breakthrough in Metalworking Technology

Metal Melting Machine Revolutionizes Industrial ManufacturingMetal manufacturing has just taken a giant leap forward with the introduction of a groundbreaking metal melting machine by a leading industrial equipment company. This innovative and state-of-the-art machine has the potential to completely revolutionize the way metal is melted and formed in the industrial sector. The company, a global leader in providing advanced manufacturing solutions, has once again demonstrated its commitment to pushing the boundaries of technology and innovation in the manufacturing industry.The new metal melting machine, which the company has dubbed the M3C-5000, is a game-changer in the field of industrial metal melting. This cutting-edge machine is capable of melting various types of metals at an unprecedented speed and efficiency, making it an ideal solution for a wide range of industrial applications. With its advanced technology and precision engineering, the M3C-5000 has the ability to melt metals at temperatures exceeding 3000 degrees Celsius, ensuring that even the most challenging metal melting tasks can be accomplished with ease.One of the key features that sets this metal melting machine apart from traditional melting equipment is its innovative heating system. Unlike conventional furnaces and melting pots, the M3C-5000 utilizes a highly efficient induction heating method, which allows for rapid and uniform heating of the metal. This not only results in significant energy savings, but also ensures that the melted metal is of the highest quality, free from impurities and imperfections.In addition to its exceptional performance, the M3C-5000 is also equipped with an advanced control system that offers unparalleled precision and flexibility. Operators have the ability to precisely control the temperature, heating rate, and melting process, allowing for customization to meet the specific requirements of each metal melting task. This level of control not only increases productivity but also ensures that the melted metal meets the strictest quality standards.Furthermore, the M3C-5000 is designed with safety and environmental sustainability in mind. The machine is equipped with advanced safety features to protect operators and minimize the risk of accidents. Additionally, the induction heating method used by the machine is inherently cleaner and more environmentally friendly than traditional melting processes, as it eliminates the need for fossil fuels and reduces harmful emissions.The introduction of the M3C-5000 metal melting machine is a testament to the company's commitment to providing innovative solutions that drive the manufacturing industry forward. With its unparalleled performance, advanced technology, and environmental considerations, this machine is set to become an indispensable tool for metal manufacturing companies around the world. It promises to streamline production processes, improve product quality, and ultimately contribute to the overall efficiency and sustainability of industrial manufacturing.The company behind this groundbreaking metal melting machine has a long-standing reputation for delivering high-quality industrial equipment and solutions to a wide range of industries. With a focus on innovation and continuous improvement, the company has established itself as a global leader in the manufacturing sector. Its commitment to research and development, combined with a dedication to meeting the evolving needs of its customers, has earned the company a strong position in the market.In conclusion, the introduction of the M3C-5000 metal melting machine represents a significant milestone in the field of industrial manufacturing. With its advanced technology, precision engineering, and environmental considerations, this machine is poised to transform the way metal is melted and formed in industrial applications. As the company continues to push the boundaries of innovation, it is clear that the M3C-5000 is just the beginning of a new era in metal manufacturing. This groundbreaking machine has the potential to drive efficiency, quality, and sustainability across the industry, solidifying the company's position as a trailblazer in the world of industrial equipment and solutions.

High Quality 100ml Silica Crucible for Laboratory Use

of the silica crucible.Silica Crucible 100ml is a reliable and high-quality product that has been designed to meet the demands of the modern laboratory. The silica crucible is made from high-grade fused silica, which provides excellent thermal stability and resistance to chemical attack. This makes it an ideal choice for use in a wide range of laboratory applications, including chemical analysis, material testing, and high-temperature heating processes.The 100ml capacity of the crucible makes it suitable for small to medium-sized sample volumes, making it a versatile and practical option for a variety of laboratory experiments. Whether it is used for melting or calcining materials, the crucible is designed to withstand extreme temperatures and thermal shock, making it a durable and reliable choice for laboratory use.In addition to its superior physical properties, the silica crucible is also designed for ease of use and handling. It features a smooth and flat bottom for stability, and a convenient pouring lip for easy decanting of the sample material. The crucible can also be easily cleaned and reused, making it a cost-effective option for laboratory operations.The company behind the Silica Crucible 100ml is a leading manufacturer of laboratory equipment and consumables. With decades of experience in the industry, the company is committed to delivering high-quality products that meet the needs of modern laboratory operations. The Silica Crucible 100ml is just one of the many products in the company's extensive catalogue, which includes a wide range of glassware, plasticware, and other essential laboratory supplies.The company prides itself on its dedication to quality and innovation, and employs a team of skilled engineers and technicians to ensure that its products meet the highest standards. All products undergo rigorous testing and quality control procedures to guarantee their performance and reliability in the laboratory setting. With a strong focus on customer satisfaction, the company is dedicated to providing excellent service and support to its clients, and is always available to address any questions or concerns about its products.In addition to its commitment to quality, the company also places a strong emphasis on sustainable and environmentally friendly business practices. It believes in responsible manufacturing and sourcing of materials, and strives to minimize its environmental impact through efficient production processes and waste management. This commitment to sustainability is reflected in the design and production of the Silica Crucible 100ml, which is made from safe and sustainable materials.The Silica Crucible 100ml has already received positive feedback from customers who have praised its performance and durability in laboratory applications. Users have reported that the crucible provides consistent and reliable results, even under demanding conditions. Its versatility and ease of use have also been highlighted as key advantages, making it a popular choice among laboratory professionals.Overall, the Silica Crucible 100ml is a practical, reliable, and high-quality product that is well-suited for a variety of laboratory applications. With its combination of excellent thermal stability, resistance to chemical attack, and ease of use, it is sure to become an essential tool for any modern laboratory. Backed by the reputation and commitment to quality of the company behind it, the Silica Crucible 100ml is a choice that laboratory professionals can trust.

Complete Guide to Metal Melting Furnace: Everything You Need to Know

Metal Melting Furnace Revolutionizes Industrial ManufacturingIn today's fast-paced industrial manufacturing environment, efficiency and reliability are key factors in maintaining a competitive edge. As industries continue to evolve, companies are constantly looking for innovative solutions to improve their manufacturing processes. With this in mind, {Company Name}, a leading provider of industrial equipment, has introduced a groundbreaking Metal Melting Furnace that is set to revolutionize the metalworking industry.{Company Name} has been at the forefront of providing cutting-edge industrial solutions for over two decades. The company is dedicated to delivering high-quality equipment that not only meets the demands of modern manufacturing but also sets new standards for performance and reliability. Their commitment to innovation and excellence has earned them a reputation as a trusted partner for businesses across various industries.The newly introduced Metal Melting Furnace is a testament to {Company Name}'s dedication to pushing the boundaries of industrial manufacturing. This state-of-the-art furnace is designed to handle the rigorous demands of melting and alloying various types of metals, providing companies with a versatile and efficient solution for their metalworking needs.One of the key features of the Metal Melting Furnace is its advanced heating technology, which ensures rapid and uniform melting of metals. This innovative heating system not only accelerates the melting process but also reduces energy consumption, making it a cost-effective solution for businesses. Additionally, the furnace is equipped with a precise temperature control system, allowing for accurate and consistent melting of metals, which is crucial for maintaining product quality and integrity.The Metal Melting Furnace also boasts a robust and durable construction, designed to withstand the harsh conditions of industrial environments. With its high-quality materials and meticulous engineering, this furnace is built to last, minimizing downtime and maintenance costs for businesses. Furthermore, the furnace is equipped with advanced safety features to ensure the protection of operators and the surrounding environment, making it a reliable and secure equipment option for businesses.One of the standout benefits of the Metal Melting Furnace is its versatility, as it is capable of melting a wide range of metals, including iron, steel, aluminum, and copper, among others. This flexibility makes it an ideal solution for businesses with diverse metalworking needs, allowing them to streamline their manufacturing processes and reduce the need for multiple furnaces.In addition to its technical capabilities, {Company Name} also offers comprehensive support and service for the Metal Melting Furnace, including installation, training, and maintenance. This commitment to customer satisfaction further solidifies {Company Name} as a trusted partner for businesses looking to enhance their manufacturing operations.The introduction of the Metal Melting Furnace comes at a time when the metalworking industry is experiencing rapid advancements and increasing demands for efficiency and productivity. With its cutting-edge technology, durable construction, and versatile capabilities, this furnace has the potential to significantly impact the way businesses approach their metal melting and alloying processes.As industries continue to evolve, companies are constantly seeking innovative solutions to improve their manufacturing processes. The Metal Melting Furnace from {Company Name} represents a significant step forward in this pursuit, providing businesses with a reliable, efficient, and versatile solution for their metalworking needs.With its advanced heating technology, precise temperature control, and robust construction, the Metal Melting Furnace is poised to set new standards for performance and reliability in the metalworking industry. Businesses can now look to {Company Name} as a trusted partner in their journey towards achieving greater efficiency and productivity in their manufacturing operations.

Electrodes Utilizing Graphite: A Breakthrough in Technology

Graphite Used As Electrodes in Innovative Application(Graphite Used As Electrodes, Date)In an era of increasingly advanced technological advancements, scientists and engineers are continuously exploring new materials and their applications, pushing the boundaries of innovation. One such material that has recently gained significant attention is graphite, which is now being utilized in an innovative way as electrodes in various industries.Graphite, a form of carbon, has long been recognized for its unique properties, making it highly sought after for numerous industrial applications. With its exceptional thermal and electrical conductivity, as well as its ability to withstand high temperatures, graphite has found a vital place in diverse fields such as metallurgy, energy storage, and electronics. The latest development in utilizing graphite lies in its use as electrodes, which has demonstrated promising results in revolutionizing certain processes.The application of graphite as electrodes holds great potential in the field of metal smelting and purification. Traditionally, electrodes made of materials like copper and steel were used in such processes. However, these materials are often prone to corrosion, limiting their lifespan and efficiency. By replacing conventional electrodes with graphite ones, researchers have managed to enhance the durability and effectiveness of these processes.Graphite electrodes have proven particularly useful in steel manufacturing. They play a crucial role in electric arc furnaces, where they deliver an electric current to melt scrap metal and facilitate its conversion into steel. Due to its high melting point and resistance to chemical reactions, graphite electrodes provide a reliable and efficient means to carry out these operations. Their ability to sustain heavy loads and withstand extreme temperatures significantly contributes to improving the productivity and quality of steel production.Moreover, the application of graphite electrodes extends beyond the realm of metallurgy. The energy storage industry has also recognized the advantages of utilizing graphite electrodes in certain battery technologies. Lithium-ion batteries, for instance, rely on graphite as an essential component for their anode, the electrode through which the electric current flows during battery operation. Graphite anodes offer an ideal balance between energy density, charge rate, and cycle life, making them indispensable for the successful functioning of lithium-ion batteries.The electronics industry, too, has witnessed a rise in the use of graphite electrodes, primarily for electrical discharge machining (EDM). This process involves removing material from workpieces through carefully controlled sparks generated between the graphite electrode and the targeted surface. The conductivity and machinability of graphite make it an ideal choice for EDM applications, ensuring precise and efficient material removal while minimizing wear on the electrode itself.The increasing demand for graphite electrodes has fueled the growth of companies specializing in their production. One such company is (), a leading manufacturer of graphite-based solutions for various industries. With their state-of-the-art facilities and expertise in graphite manufacturing, they are at the forefront of providing high-quality electrodes to meet the growing industry requirements. By continually innovating and investing in research and development, they aim to further enhance the capabilities and applications of graphite electrodes.As graphite continues to make its mark as a crucial material in various industries, further advancements and applications are expected to emerge. With constant innovation, researchers, scientists, and engineers will undoubtedly unearth new possibilities for the utilization of graphite electrodes. From improving metal smelting and purification processes to enhancing battery technologies and electrical discharge machining, graphite electrodes are poised to revolutionize multiple sectors. The continued collaboration between industry leaders and research institutions will play a pivotal role in harnessing the full potential of graphite as electrodes, opening new horizons for industrial applications in the future.

Top-quality Crucibles for Industrial Use

Flamefast Crucible, a leading manufacturer in the field of industrial and laboratory technology, has recently introduced a new cutting-edge product that is set to revolutionize the industry. The Flamefast Crucible is an innovative and advanced piece of equipment designed to withstand high temperatures and provide a reliable and efficient solution for a variety of industrial and laboratory applications. With its state-of-the-art technology and exceptional performance, the Flamefast Crucible is set to become the go-to choice for businesses and professionals in need of a high-quality crucible.The Flamefast Crucible is the latest addition to the company's extensive range of industrial and laboratory equipment. With a dedication to pushing the boundaries of technological innovation, Flamefast Crucible has consistently delivered exceptional products to cater to the evolving needs of its customers. The company's commitment to research and development, combined with its unparalleled expertise in the industry, has allowed it to stay at the forefront of technological advancements and provide its customers with cutting-edge solutions.The new Flamefast Crucible is engineered to deliver exceptional performance under extreme conditions. Its high-quality materials and precision engineering make it highly resistant to corrosion and wear, ensuring a long service life and reliable performance. The crucible is capable of withstanding high temperatures, making it ideal for applications in foundries, laboratories, and various industrial processes. Its robust design and advanced features make it an indispensable asset for businesses that demand durability and consistent performance from their equipment.One of the key features that sets the Flamefast Crucible apart from its competitors is its advanced thermal insulation. The crucible is designed to minimize heat loss and ensure uniform heating, resulting in superior performance and energy efficiency. This not only helps businesses reduce their energy costs but also enhances the overall productivity and effectiveness of their operations. The Flamefast Crucible is also designed to be user-friendly, with intuitive controls and easy maintenance, making it a practical and convenient solution for professionals in various industries.Flamefast Crucible has also taken steps to ensure the safety and reliability of its product. The crucible is equipped with multiple safety features to prevent accidents and ensure the well-being of operators and personnel. This includes comprehensive thermal protection and advanced monitoring systems that provide real-time information on crucial operating parameters. As a result, businesses can have peace of mind knowing that the Flamefast Crucible is designed to operate safely and effectively, even under the most challenging conditions.In addition to its technical capabilities, the Flamefast Crucible is also backed by Flamefast Crucible's renowned customer support and service. The company is dedicated to providing exceptional support to its customers, offering comprehensive assistance and guidance to ensure the optimal performance and longevity of its products. This commitment to customer satisfaction has earned Flamefast Crucible a strong reputation in the industry, with many businesses relying on its expertise and support for their industrial and laboratory needs.Overall, the introduction of the Flamefast Crucible marks a significant milestone for Flamefast Crucible and the industry as a whole. With its cutting-edge technology, exceptional performance, and unwavering commitment to customer satisfaction, the Flamefast Crucible is set to become a game-changer in the field of industrial and laboratory equipment. Businesses and professionals seeking a reliable, high-performance crucible need look no further than the Flamefast Crucible, the latest innovation from the industry leader.