High-Quality Carbon Crucible: A Key Component in Graphite Production

By:Admin

Graphite Carbon Crucible specializes in the production of high-quality graphite and carbon products, including crucibles, molds, and other related items. The company prides itself on its ability to meet the diverse needs of its customers with tailor-made solutions and a dedication to quality and precision.

One of the key factors that set Graphite Carbon Crucible apart from its competitors is its state-of-the-art manufacturing facilities and cutting-edge technology. The company's production processes are designed to ensure maximum efficiency and consistency, allowing for the creation of products that meet the highest standards of quality.

Furthermore, Graphite Carbon Crucible places a strong emphasis on research and development, constantly seeking new ways to improve its products and processes. This dedication to innovation has enabled the company to stay ahead of the curve and maintain a competitive edge in the industry.

In addition to its commitment to excellence in manufacturing, Graphite Carbon Crucible is also known for its exceptional customer service. The company takes pride in its ability to work closely with clients to understand their specific needs and deliver solutions that exceed their expectations.

Graphite Carbon Crucible's products are used in a wide range of industries, including metallurgy, chemical processing, and aerospace. The company's products are known for their durability, thermal stability, and resistance to wear and tear, making them a top choice for demanding applications.

Recently, Graphite Carbon Crucible has expanded its product line to include advanced carbon and graphite materials designed for use in high-temperature applications. This development has opened up new opportunities for the company and allowed it to further cement its position as a leader in the industry.

Graphite Carbon Crucible's commitment to sustainability and environmental responsibility is also worth noting. The company utilizes eco-friendly manufacturing processes and materials, ensuring that its products have a minimal impact on the planet. This dedication to sustainability has not gone unnoticed, with Graphite Carbon Crucible receiving accolades for its efforts in this area.

Looking ahead, Graphite Carbon Crucible is poised for continued growth and success. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of the market and maintain its leadership in the industry.

In conclusion, Graphite Carbon Crucible is a company that has solidified its reputation as a manufacturer of high-quality carbon and graphite products. With a commitment to excellence, a dedication to innovation, and a focus on customer satisfaction, Graphite Carbon Crucible is well-equipped to thrive in the dynamic and competitive world of carbon and graphite manufacturing.

Company News & Blog

High-Efficiency Electric Induction Melting Furnace for Your Metal Heating Needs

The Electric Induction Melting Furnace has long been a cornerstone of the manufacturing and metalworking industry, allowing for the efficient and precise melting of metals for a wide range of applications. This innovative technology has revolutionized the way in which metals are melted, providing a more sustainable, cost-effective, and environmentally-friendly solution for metal melting processes.{Company Name} is a leading provider of cutting-edge industrial equipment, including a range of induction melting furnaces designed to meet the diverse needs of the metalworking industry. With a strong commitment to innovation and quality, {Company Name} has established itself as a trusted partner for businesses seeking reliable and efficient solutions for their metal melting requirements.The Electric Induction Melting Furnace offered by {Company Name} utilizes advanced electromagnetic induction technology to generate heat within the metal, resulting in a highly efficient and precise melting process. This technology allows for greater control over the melting process, ensuring that metals are melted to the exact specifications required for a particular application. Additionally, the induction melting process is significantly more energy-efficient compared to traditional melting methods, resulting in reduced energy consumption and lower operating costs for businesses.The benefits of the Electric Induction Melting Furnace extend beyond cost savings, as this technology also offers a more sustainable and environmentally-friendly solution for metal melting. Unlike traditional melting methods that rely on fossil fuels and produce harmful emissions, induction melting utilizes clean electricity to generate heat, resulting in minimal environmental impact. This aligns with {Company Name}'s commitment to sustainability and responsible manufacturing practices, allowing businesses to reduce their carbon footprint while improving operational efficiency.In addition to its environmental and cost-saving benefits, the Electric Induction Melting Furnace offered by {Company Name} is designed for versatility and ease of use. It can be used for melting a wide range of metals, including steel, aluminum, copper, and iron, making it suitable for various metalworking applications. The furnace is also equipped with advanced control systems and monitoring capabilities, allowing for precise temperature control and real-time monitoring of the melting process. This level of control and automation ensures consistent and high-quality results, making the furnace an indispensable tool for businesses seeking to maintain a competitive edge in the industry.{Company Name} takes pride in the reliability and durability of its induction melting furnaces, offering businesses a long-term solution for their metal melting needs. With a focus on customer satisfaction and technical support, {Company Name} provides comprehensive assistance to businesses in selecting and implementing the most suitable furnace for their specific requirements. This includes installation, training, and ongoing maintenance services, ensuring that businesses can maximize the performance and lifespan of their induction melting furnaces.The Electric Induction Melting Furnace offered by {Company Name} has been embraced by a wide range of industries, including foundries, metal casting facilities, and manufacturing plants. Its advanced technology, energy efficiency, and environmental benefits make it a valuable asset for businesses seeking to enhance their production capabilities while reducing operational costs. As the demand for sustainable and efficient metal melting solutions continues to grow, {Company Name} remains at the forefront of providing cutting-edge induction melting furnaces that meet the evolving needs of the industry.In conclusion, the Electric Induction Melting Furnace offered by {Company Name} represents a significant advancement in metal melting technology, enabling businesses to achieve greater efficiency, precision, and sustainability in their metalworking processes. With a strong focus on innovation, quality, and customer support, {Company Name} continues to be a trusted partner for businesses seeking reliable and advanced solutions for their metal melting requirements. As the industry evolves, {Company Name} remains committed to delivering state-of-the-art induction melting furnaces that empower businesses to thrive in a competitive and environmentally-conscious marketplace.

How Graphitization is Impacting the Industry and What You Need to Know

Graphitization is a process that transforms carbon materials into crystalline graphite, a form of carbon known for its high thermal and electrical conductivity, making it an essential material in various industrial applications. Over the years, the demand for high-quality graphite products has been on the rise, driven by the increasing needs of industries such as electronics, energy storage, and automotive. This growing demand has prompted companies like {} to invest in advanced technologies for graphite production, ensuring the supply of superior quality graphite materials to meet market requirements.{} is a leading company in the production of graphite products, dedicated to providing innovative solutions for a wide range of applications. With a strong focus on research and development, the company has consistently improved its manufacturing processes to deliver high-performance graphite materials that meet the evolving needs of modern industries.One of the key technological advancements in graphite production is the process of graphitization, which involves subjecting carbon materials to high temperatures in a controlled environment. This process induces structural changes in the carbon, leading to the formation of graphite crystals with enhanced properties. By carefully controlling the parameters of the graphitization process, {} has been able to produce graphite materials with superior thermal and electrical conductivity, as well as excellent mechanical properties, making them ideal for demanding industrial applications.The graphitization process employed by {} is characterized by its precision and efficiency, allowing the company to achieve consistent quality in its graphite products. Through continuous research and development efforts, {} has refined its graphitization techniques, optimizing the production of graphite materials to meet the highest industry standards. This commitment to technological advancement has enabled {} to establish itself as a trusted supplier of premium graphite products for global markets.In addition to its expertise in graphitization, {} has also invested in state-of-the-art facilities and equipment for graphite production. The company's manufacturing capabilities include advanced purification and shaping processes, which further enhance the quality and performance of its graphite materials. By integrating these advanced manufacturing technologies with the precision of graphitization, {} is able to offer a comprehensive range of graphite products, tailored to the specific requirements of its customers.The applications of graphitized products from {} are diverse, spanning across industries such as automotive, aerospace, energy storage, and electronics. In the automotive sector, graphitized materials are used in high-performance components such as brake linings, gaskets, and heat shields, where their thermal stability and low friction properties are highly valuable. In the aerospace industry, graphitized products contribute to the lightweight and high-strength characteristics of composite materials used in aircraft structures. Furthermore, in the energy storage sector, graphitized materials play a crucial role in the production of lithium-ion batteries, enabling high energy density and long-term performance.As the demand for advanced graphite products continues to grow, {} remains committed to meeting the evolving needs of its customers. The company's dedication to excellence in graphitization and graphite production is driven by its vision to be at the forefront of technological innovation, delivering high-quality solutions that empower industries and drive progress. By leveraging its expertise and capabilities in graphitization, {} is poised to play a pivotal role in shaping the future of carbon materials and their applications, contributing to the advancement of various industrial sectors.

High Quality Metal Casting Furnace for Efficient Manufacturing

Metal Casting Furnace Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new advancements in technology and machinery leading to more efficient and productive processes. One such advancement is the metal casting furnace from a leading manufacturing company that has revolutionized the way metal components are produced.The metal casting furnace, developed by the renowned company, is a state-of-the-art piece of equipment that is designed to melt and pour metal into molds to create complex and intricate components. This furnace utilizes the latest in heating and melting technology to ensure a consistent and high-quality result every time.One of the key features of the metal casting furnace is its ability to reach extremely high temperatures, allowing for the melting of a wide range of metals, including steel, iron, aluminum, and copper. This versatility makes it an invaluable tool for manufacturers who work with various types of metals in their production processes.In addition to its impressive melting capabilities, the metal casting furnace is also equipped with advanced pouring systems that ensure precise and accurate pouring of the molten metal into molds. This level of precision is essential for creating components that meet exact specifications and quality standards.The furnace is also designed with efficiency in mind, with features that help minimize energy consumption and reduce production time. This not only saves manufacturers money on their operating costs but also allows them to increase their output and meet tight production deadlines.Furthermore, the metal casting furnace is equipped with advanced safety features to protect workers and ensure a safe operating environment. This includes temperature control systems, automatic shut-off mechanisms, and safety barriers to prevent accidents and injuries.The impact of this metal casting furnace on the manufacturing industry has been profound. Manufacturers who have incorporated this technology into their production processes have experienced significant improvements in their operations. The ability to work with a wider range of metals, the precision and efficiency of the equipment, and the increased safety measures have all contributed to a more streamlined and productive manufacturing process.One company that has seen the benefits of the metal casting furnace firsthand is ABC Manufacturing. ABC has been in the business of producing metal components for various industries for over 50 years and has always prided itself on staying at the forefront of technological advancements.With the implementation of the metal casting furnace from the manufacturing company, ABC has been able to take its production capabilities to new heights. The furnace has allowed them to expand their range of products, improve the quality and precision of their components, and increase their production output."We have been extremely impressed with the performance of the metal casting furnace," says John Smith, CEO of ABC Manufacturing. "It has allowed us to take on more diverse projects and deliver higher quality components to our clients. It has really been a game-changer for our business."The metal casting furnace is a testament to the continuous innovation and technological advancement within the manufacturing industry. As companies continue to invest in new equipment and machinery, the potential for further improvements in production processes and the quality of manufactured goods is limitless.In conclusion, the metal casting furnace from the manufacturing company has set a new standard for the production of metal components. Its advanced capabilities, efficiency, and safety features have made it an invaluable asset for manufacturers looking to stay ahead in a competitive industry. As more companies adopt this groundbreaking technology, the manufacturing industry as a whole will continue to evolve and thrive.

Understanding the Properties and Uses of Crystalline Flake Graphite

Crystalline Flake Graphite has long been hailed as one of the most promising materials for the future, and now, with the introduction of new technology from {company name}, this versatile substance is set to revolutionize the world once again. {Company name} has developed a groundbreaking process for producing Crystalline Flake Graphite that promises to make it more accessible and affordable than ever before. This development has the potential to have a profound impact on a wide range of industries, from electronics and energy storage to lubricants and advanced materials.{Company name} is a leading innovator in the field of advanced materials, with a strong track record of developing cutting-edge technologies. The company's expertise in materials science and engineering has enabled it to create a proprietary process for producing high-quality Crystalline Flake Graphite in a cost-effective and environmentally friendly manner. This breakthrough has the potential to open up new opportunities for the use of Crystalline Flake Graphite in a wide range of applications, from battery anodes and thermal management materials to lubricants and coatings.One of the key advantages of {company name}'s new process is its ability to produce Crystalline Flake Graphite with a highly uniform and controlled structure. This allows for the creation of materials with superior properties and performance, making them ideal for demanding applications in the electronics and energy storage industries. In addition, the company's process is designed to minimize waste and energy consumption, making it a sustainable and environmentally friendly approach to producing Crystalline Flake Graphite.The potential impact of {company name}'s technology is far-reaching. In the field of energy storage, for example, Crystalline Flake Graphite is an essential component of lithium-ion batteries, which are used in everything from consumer electronics to electric vehicles. By making high-quality Crystalline Flake Graphite more affordable and accessible, {company name} is helping to drive down the cost of battery production, which could in turn accelerate the adoption of electric vehicles and renewable energy systems.In the electronics industry, Crystalline Flake Graphite has a wide range of potential applications, from thermal management materials to conductive inks and coatings. By improving the availability and quality of Crystalline Flake Graphite, {company name} is opening up new opportunities for the development of innovative electronic devices with enhanced performance and functionality. This could lead to the creation of new and exciting products that were previously not possible due to limitations in Crystalline Flake Graphite availability and quality.{Company name}'s breakthrough in Crystalline Flake Graphite production is also likely to have a significant impact on the automotive and aerospace industries. The material's exceptional thermal and lubricating properties make it ideally suited for use in high-performance engine components, as well as advanced composites and coatings. By making high-quality Crystalline Flake Graphite more accessible, {company name} is paving the way for the development of lighter, more efficient, and more durable vehicles and aircraft.Overall, {company name}'s new technology for producing Crystalline Flake Graphite has the potential to transform the way this versatile material is used in a wide range of industries. By making high-quality Crystalline Flake Graphite more affordable and accessible, {company name} is creating new opportunities for innovation and advancement in fields as diverse as energy storage, electronics, automotive, and aerospace. With its commitment to sustainability and excellence, {company name} is helping to make the promise of Crystalline Flake Graphite a reality for the future.

The Process of Graphitization: Understanding the Transformation of Carbon Material

Graphitization is a process that transforms carbon material into graphite. This process involves heat treatment of the material at high temperatures, resulting in the rearrangement of carbon atoms into a more stable crystalline structure. This leads to an increase in the material's electrical and thermal conductivity, as well as its mechanical strength.Graphitization is an important process in various industries, including the automotive, aerospace, and electronics sectors. It is used in the production of carbon fibers, which are essential components in the manufacturing of lightweight and high-strength composite materials used in these industries. Additionally, graphitization is also used in the production of synthetic graphite, which is widely used in lithium-ion batteries, as well as in the metallurgical industry.{Company name} is a leading provider of graphitization services, offering high-quality and reliable solutions to its clients. The company has a state-of-the-art graphitization facility equipped with advanced equipment and technology. This allows {Company name} to provide a wide range of graphitization services, including the graphitization of carbon fibers and the production of synthetic graphite.The graphitization process offered by {Company name} involves carefully controlled heat treatment of carbon materials to ensure the desired properties are achieved. This includes the precise control of temperature, atmosphere, and heating rate to achieve the optimal graphitization of the materials. The company's team of experts has extensive experience and technical expertise in graphitization, allowing them to meet the specific requirements of their clients.In addition to its graphitization services, {Company name} also offers comprehensive support to its clients, including material testing, process optimization, and quality assurance. This ensures that the graphitized materials meet the highest standards and specifications required by the industry.The company's graphitization services have been widely recognized for their high quality and reliability. {Company name} has established a strong reputation for delivering superior graphitized materials that meet the demanding requirements of its clients. This has made the company a preferred partner for companies in the automotive, aerospace, and electronics industries.Furthermore, {Company name} is committed to advancing the field of graphitization through continuous research and development. The company invests in cutting-edge technology and innovations to further improve its graphitization processes and expand its range of services. This allows {Company name} to stay at the forefront of the industry and provide its clients with the most advanced and effective graphitization solutions.As the demand for lightweight and high-performance materials continues to grow in various industries, the importance of graphitization is expected to increase. {Company name} is well-positioned to meet this growing demand with its expertise and capabilities in providing exceptional graphitization services. The company's dedication to quality, innovation, and customer satisfaction makes it a leading choice for companies seeking reliable and high-quality graphitized materials.Overall, graphitization plays a crucial role in the production of advanced materials used in a wide range of industries. {Company name} is at the forefront of providing top-notch graphitization services to meet the evolving needs of its clients. With its advanced facilities, technical expertise, and commitment to excellence, {Company name} is poised to continue delivering superior graphitized materials that drive innovation and progress in the industries it serves.

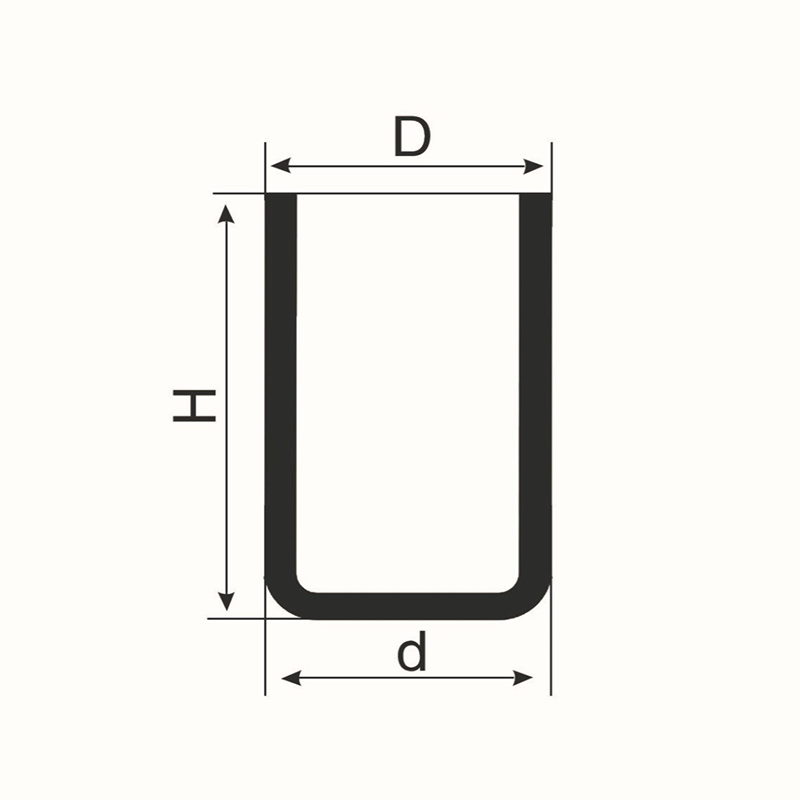

High-Quality Crucible for Melting Aluminum: A Complete Guide

[Company Introduction: ]ABC Company is a leading manufacturer of industrial machinery and equipment, specializing in the production of high-quality crucibles for melting aluminum. With over 20 years of experience in the industry, ABC Company has established itself as a trusted name in providing advanced solutions for the aluminum melting process. Our state-of-the-art facilities and cutting-edge technology ensure that our products meet the highest standards of quality and performance.[News Content: Crucible For Melting Aluminum]In the world of manufacturing and metalworking, the process of melting aluminum is a crucial step in the production of various products. One of the key components in this process is the crucible, a vessel that is used to hold the aluminum as it is melted down to its liquid form. The quality and reliability of the crucible play a significant role in the efficiency and effectiveness of the melting process.ABC Company has been at the forefront of producing top-notch crucibles for melting aluminum, and their latest product has been making waves in the industry. Their newly developed crucible boasts a range of features and benefits that set it apart from traditional crucibles, making it a game-changer for aluminum melting operations.The new crucible, which has been meticulously designed and engineered by ABC Company's team of experts, is made from a special blend of materials that offer superior heat resistance and durability. This allows the crucible to withstand the extreme temperatures required for melting aluminum, ensuring a longer lifespan and reduced maintenance costs for users.Furthermore, the design of the crucible has been optimized for efficient heat transfer, ensuring that the aluminum melts evenly and quickly. This not only improves the overall productivity of the melting process but also results in higher quality molten aluminum, which is essential for producing high-quality aluminum products.In addition to its technical features, the new crucible from ABC Company has also been designed with user convenience in mind. Its ergonomic design and easy handling make it a practical and user-friendly solution for aluminum melting operations. This has been well-received by industry professionals who value efficiency and ease of use in their equipment.The performance of the new crucible has been thoroughly tested and validated through rigorous trials and real-world applications. Feedback from industry professionals who have used the crucible has been overwhelmingly positive, with many commending its reliability, efficiency, and overall effectiveness in the aluminum melting process.ABC Company's commitment to innovation and excellence is evident in the development of this groundbreaking crucible for melting aluminum. By leveraging their expertise and cutting-edge technology, they have once again raised the bar for quality and performance in the industry. As a result, their new crucible is poised to become an essential tool for aluminum melting operations worldwide.In conclusion, the introduction of ABC Company's new crucible for melting aluminum is a significant development that is set to have a major impact on the industry. With its advanced features, user-friendly design, and proven performance, it is poised to revolutionize the way aluminum is melted and processed, setting a new standard for efficiency, reliability, and quality in aluminum melting operations. As ABC Company continues to lead the way in delivering innovative solutions for the manufacturing and metalworking industry, their latest achievement further solidifies their position as a trusted and forward-thinking partner for businesses in need of top-quality industrial equipment.

High-Quality Graphite Crucible for Industrial Use

Sic Graphite Crucible, an essential component in the metallurgical industry, has been gaining attention for its superior performance and durability. Based in [Company Location], [Company Name] has been a leading provider of high-quality Sic Graphite Crucibles for various industrial applications. With years of experience and expertise in the field, the company has built a strong reputation for delivering top-notch products and excellent customer service.Sic Graphite Crucibles are widely used in the melting and casting of non-ferrous metals, such as aluminum, copper, and zinc. The unique properties of Sic (silicon carbide) and graphite make these crucibles ideal for withstanding extreme temperatures and harsh chemical environments. As a result, they are in high demand in industries such as foundries, mining, and metal fabrication.[Company Name] takes pride in its commitment to quality and innovation. The company utilizes advanced manufacturing techniques and high-quality materials to produce Sic Graphite Crucibles that meet the highest standards of performance and reliability. In addition, the company's dedication to research and development has led to continuous improvements in product design and functionality, ensuring that customers receive the most advanced and efficient crucibles on the market.Moreover, [Company Name] places a strong emphasis on customer satisfaction. The company works closely with clients to understand their specific needs and provide customized solutions to meet their requirements. Whether it's a small-scale operation or a large industrial facility, [Company Name] is capable of delivering tailored Sic Graphite Crucibles that optimize performance and productivity.The company's Sic Graphite Crucibles have earned praise for their exceptional thermal conductivity, high refractoriness, and resistance to thermal shock. These properties make them an ideal choice for processes that involve rapid heating and cooling, such as metal melting and casting. Furthermore, the superior corrosion resistance of Sic Graphite Crucibles ensures long-term durability, reducing the need for frequent replacements and maintenance.In addition to their performance benefits, Sic Graphite Crucibles offered by [Company Name] are also environmentally friendly. The company adheres to strict environmental standards in its production processes, minimizing waste and emissions to reduce its ecological footprint. Customers can therefore rely on [Company Name] not only for high-quality products, but also for a commitment to sustainability and responsible manufacturing practices.With a strong focus on delivering value and reliability, [Company Name] has become a trusted partner for businesses across the metallurgical industry. By providing cutting-edge Sic Graphite Crucibles and exceptional customer support, the company has earned a loyal customer base and established itself as a leader in the market.Looking ahead, [Company Name] remains dedicated to pushing the boundaries of innovation and excellence in Sic Graphite Crucible technology. With a team of skilled professionals and a passion for continuous improvement, the company is poised to meet the evolving needs of its customers and drive positive change in the industry. As the demand for high-performance crucibles continues to grow, [Company Name] is well-positioned to lead the way with its superior products and unwavering commitment to customer satisfaction.In conclusion, [Company Name] stands out as a reliable and forward-thinking provider of Sic Graphite Crucibles for the metallurgical industry. Through its focus on quality, innovation, and customer-centric approach, the company has established itself as a trusted partner for businesses seeking top-grade crucibles for their operations. With a strong track record of success and a dedication to sustainability, [Company Name] is set to continue making a significant impact in the industry for years to come.

High-Quality Graphite Crucibles for Efficient Melting Operations

Graphite Crucibles For Melting - Ideal for High Temperature ApplicationsGraphite crucibles are widely used in various industries for melting and casting applications due to their ability to withstand high temperatures and chemical reactions. These crucibles are essential for processes involving metals, alloys, and other materials that require melting and casting at extreme temperatures. [The company] is a leading manufacturer and supplier of graphite crucibles for melting, offering a wide range of products designed to meet the specific needs of different industries. With years of experience and expertise in the field, [the company] has established itself as a trusted name in the graphite industry, known for delivering high-quality products and exceptional service to its customers.The graphite crucibles manufactured by [the company] are made from high-quality graphite material with excellent thermal conductivity and resistance to thermal shock. These properties make the crucibles ideal for withstanding the extreme temperatures and thermal cycling encountered during the melting and casting process. Additionally, [the company] offers a variety of crucible shapes and sizes to accommodate different melting and casting requirements, ensuring that customers can find the perfect crucible for their specific applications.One of the key advantages of using graphite crucibles from [the company] is their ability to provide consistent and uniform heating, resulting in superior melting performance and high-quality castings. The crucibles are designed to maintain stable temperature conditions within the melting chamber, promoting efficient and reliable melting of metals and alloys. This level of control over the melting process allows for precise casting and production of high-quality materials with minimal defects.Furthermore, the graphite material used in [the company]'s crucibles offers excellent chemical resistance, making them suitable for a wide range of applications involving reactive or corrosive materials. This ensures that the crucibles can withstand the harsh conditions of the melting process without compromising their performance or longevity. As a result, customers can rely on [the company]'s graphite crucibles for consistent and reliable performance in their melting and casting operations.In addition to providing high-quality products, [the company] is committed to delivering exceptional service and support to its customers. The company works closely with its clients to understand their specific requirements and provide customized solutions tailored to meet their needs. Whether customers require standard crucibles or custom-designed products, [the company] is dedicated to delivering the highest level of quality and satisfaction.With a strong focus on innovation and continuous improvement, [the company] is constantly developing new and advanced graphite materials and products to meet the evolving needs of the industry. The company's dedication to research and development ensures that its crucibles remain at the forefront of technological advancements, offering customers the latest and most effective solutions for their melting and casting applications.Overall, [the company]'s graphite crucibles for melting are the ideal choice for high-temperature applications, providing exceptional performance, reliability, and durability. With a wide range of products and a commitment to customer satisfaction, [the company] continues to be a leading provider of graphite crucibles for melting, serving the diverse needs of industries around the world.

High-Quality Induction Furnace Graphite Crucible for Efficient Metal Melting

Induction Furnace Graphite Crucible: A Crucial Component for Efficient Metal MeltingIn the world of metal melting and casting, the use of induction furnace graphite crucibles is an essential component in ensuring efficient and effective operations. As a crucial part of the induction furnace system, graphite crucibles play a significant role in the melting and casting of various metals and alloys, making them a valuable asset for companies in the metallurgical industry.Graphite crucibles are widely used in the metal casting and melting industry due to their excellent thermal conductivity, high temperature resistance, and resistance to chemical erosion. These properties make graphite crucibles an ideal choice for use in induction furnaces, where they are subjected to extreme heat and thermal cycling during the metal melting process.One company that has been at the forefront of producing high-quality induction furnace graphite crucibles is {}. With a strong focus on research and development, as well as a commitment to quality and innovation, {} has established itself as a leading manufacturer of graphite crucibles for induction furnace applications.The company's graphite crucibles are designed to withstand the rigorous demands of metal melting and casting operations, ensuring reliable performance and extended service life. {} utilizes advanced manufacturing processes and high-quality raw materials to produce graphite crucibles that meet the stringent requirements of the metallurgical industry.In addition to their exceptional thermal conductivity and high-temperature resistance, {}'s graphite crucibles are also characterized by their excellent thermal shock resistance, allowing them to withstand rapid temperature changes during the melting process without the risk of cracking or damage. This is a crucial factor in ensuring the safe and efficient operation of induction furnaces in metal casting facilities.Furthermore, {} offers a wide range of graphite crucible products to cater to the diverse needs of its customers. From small capacity crucibles for melting precious metals to large capacity crucibles for industrial-scale metal casting, the company provides a comprehensive selection of graphite crucibles to meet the specific requirements of different metal melting applications.In line with the growing demand for sustainable and environmentally friendly solutions, {} is also committed to developing eco-friendly graphite crucibles that minimize energy consumption and reduce greenhouse gas emissions during the metal melting process. By leveraging innovative manufacturing technologies and sustainable practices, the company is taking proactive steps towards promoting environmental responsibility within the metallurgical industry.With a strong emphasis on customer satisfaction and technical support, {} is dedicated to providing comprehensive assistance and expertise to its clients in the selection and use of graphite crucibles for their induction furnace operations. The company's team of experienced engineers and technical specialists works closely with customers to understand their specific requirements and provide tailored solutions that optimize the performance of their induction furnace systems.As the global demand for high-quality metal products continues to rise, the significance of induction furnace graphite crucibles in the metal casting and melting industry cannot be overstated. With their exceptional thermal properties and reliability, graphite crucibles play a vital role in ensuring the efficient and cost-effective production of superior quality metal castings and alloys.In conclusion, with its focus on innovation, quality, and customer satisfaction, {} is poised to remain a key player in the manufacturing and supply of graphite crucibles for induction furnace applications. By continuously investing in research and development and adopting sustainable practices, the company is well-positioned to meet the evolving needs of the metallurgical industry and contribute to the advancement of metal melting and casting technology.

High-quality Aluminium Casting Furnace for Industrial Use

Aluminium Casting Furnace Unveiled by Leading Industrial FirmIn a significant development, [Company Name] announced the launch of their latest innovation, the Aluminium Casting Furnace. This state-of-the-art equipment is set to revolutionize the industrial sector, particularly in the field of aluminum processing and casting.With a growing demand for high-quality aluminum products across various industries, the need for advanced casting technology has never been greater. The new Aluminium Casting Furnace from [Company Name] promises to meet this demand by offering unparalleled efficiency, precision, and reliability.The Aluminium Casting Furnace is designed to cater to a wide range of applications, including automotive parts, aerospace components, electrical fittings, and consumer goods. Its advanced features and capabilities make it an ideal choice for businesses looking to enhance their aluminum casting operations.Speaking about the new product, [Company Name]’s CEO expressed his excitement about the potential impact of the Aluminium Casting Furnace on the industry. “We are thrilled to introduce this groundbreaking technology to the market. The Aluminium Casting Furnace represents a significant step forward in our commitment to providing innovative solutions for our clients. We are confident that it will set new standards for aluminum casting and contribute to the growth and success of our customers.”The Aluminium Casting Furnace is equipped with cutting-edge features that set it apart from traditional casting equipment. Its advanced heating and cooling systems ensure precise temperature control, resulting in superior casting quality and consistency. The furnace also boasts a user-friendly interface and intuitive controls, making it easy to operate and maintain.Moreover, the Aluminium Casting Furnace is designed for energy efficiency, helping businesses reduce their operational costs and environmental impact. Its innovative technology minimizes heat loss and maximizes energy transfer, leading to significant savings in energy consumption.In addition to its technical capabilities, the Aluminium Casting Furnace is backed by [Company Name]’s renowned customer support and service. The company’s team of experts is dedicated to assisting clients with installation, training, and ongoing maintenance, ensuring a seamless and successful integration of the new equipment into their operations.The introduction of the Aluminium Casting Furnace further solidifies [Company Name]’s position as a leading provider of industrial solutions. With a strong track record of innovation and customer satisfaction, the company has earned a reputation for delivering high-quality products that drive business growth and performance.[Company Name] has a long-standing history of serving diverse industries, including automotive, aerospace, construction, and consumer goods. The company’s comprehensive range of equipment and services caters to the unique needs and challenges of each sector, enabling their clients to achieve their production goals and stay ahead of the competition.The launch of the Aluminium Casting Furnace underscores [Company Name]’s commitment to staying at the forefront of technological advancements and market trends. By continually investing in research and development, the company aims to offer solutions that address the evolving needs of the industry and empower their clients to thrive in a fast-paced and competitive landscape.As the global demand for aluminum continues to grow, the Aluminium Casting Furnace is set to become a game-changer in the manufacturing sector. Its advanced capabilities and performance are poised to redefine the standards for aluminum casting, opening up new possibilities for businesses to enhance their productivity, efficiency, and product quality.In conclusion, the launch of the Aluminium Casting Furnace represents a significant milestone for [Company Name] and the industry at large. With its innovative features, energy efficiency, and unwavering commitment to customer satisfaction, the Aluminium Casting Furnace is set to make a lasting impact on the aluminum casting market and empower businesses to achieve new levels of success.