Raw Material Used in Graphite Electrode Manufacturing

By:Admin

{Company Name} is a renowned producer of high-quality Graphite Electrode Raw Material, with a strong focus on innovation and sustainability. The company prides itself on its advanced production facilities and state-of-the-art technology, which enable it to meet the growing demands of the global market.

The Graphite Electrode Raw Material produced by {Company Name} is characterized by its exceptional purity and superior performance, making it an ideal choice for use in electric arc furnaces. The company's commitment to quality and excellence has earned it a solid reputation among its clients, who rely on its products for their critical applications in the steel and metallurgical industries.

With the ongoing expansion of the steel industry, the demand for Graphite Electrode Raw Material is expected to continue rising in the coming years. This trend is driven by the increasing need for high-quality and cost-effective raw materials to support the production of steel, which is a crucial component in various sectors such as construction, automotive, and infrastructure development.

To cater to this growing demand, {Company Name} has adopted a proactive approach to enhance its production capacity and efficiency. The company has invested in the latest technologies and equipment to optimize its manufacturing processes, thereby ensuring a steady and reliable supply of Graphite Electrode Raw Material to its global clientele.

Furthermore, {Company Name} is committed to sustainability and environmental responsibility in its operations. The company adheres to stringent environmental standards and practices, minimizing its carbon footprint and promoting the efficient use of resources. This approach not only benefits the environment but also aligns with the growing emphasis on sustainable business practices among industry players and consumers.

In addition to its focus on sustainability, {Company Name} places a strong emphasis on research and development to continually improve its product offerings. The company has a dedicated team of experts and scientists who are constantly exploring new technologies and materials to enhance the performance and efficiency of its Graphite Electrode Raw Material. This dedication to innovation has allowed {Company Name} to stay ahead of the competition and cater to the evolving needs of its customers.

As a global leader in the production of Graphite Electrode Raw Material, {Company Name} is well-positioned to capitalize on the increasing demand for its products. The company has a robust distribution network that spans across key markets, allowing it to efficiently reach its customers and fulfill their requirements in a timely manner.

Looking ahead, {Company Name} remains committed to further strengthening its position in the market and expanding its product portfolio to meet the diverse needs of its customers. With its unwavering focus on quality, innovation, and sustainability, {Company Name} is poised to continue its success as a trusted provider of high-quality Graphite Electrode Raw Material for the steel industry and beyond.

Company News & Blog

High Quality Casting Furnaces: A Guide to Choosing the Best Option

Casting Furnaces are a crucial component in the manufacturing industry, especially for companies like {} that specialize in metal casting. These furnaces are used to melt and pour metal into molds, creating a wide range of products from automotive parts to kitchen cookware.{} is a leading company in the field of metal casting, with a strong focus on innovation and quality. The company has been in operation for over 50 years and has established itself as a trusted partner for many manufacturers around the world. With a strong commitment to excellence, {} has continuously invested in state-of-the-art equipment to ensure the highest quality products for its customers.One of the key pieces of equipment in {}'s manufacturing process is its casting furnaces. These furnaces are essential for melting various types of metals, such as aluminum, iron, and steel, at high temperatures. The molten metal is then poured into molds to create the desired shape and form. {}'s casting furnaces are designed to meet the strict requirements of the industry, ensuring precise temperature control and consistent results.Recently, {} has made significant advancements in its casting furnace technology, which has allowed the company to improve its manufacturing process and produce even better quality products. The new casting furnaces are equipped with advanced features such as automatic temperature control, energy-efficient heating elements, and innovative safety measures to ensure a smooth and reliable operation.In addition to the technological advancements, {} has also focused on sustainability and environmental responsibility in its manufacturing process. The new casting furnaces are designed to minimize energy consumption and reduce emissions, aligning with {}'s commitment to sustainable practices.With the introduction of these new casting furnaces, {} has been able to increase its production capacity and meet the growing demand for its products. The improved efficiency and quality of the casting process have allowed the company to expand its product range and offer a wider variety of options to its customers.Furthermore, {}'s investment in advanced casting furnace technology has also positioned the company as a leader in the industry. The innovative approach to manufacturing has set a new standard for quality and reliability, distinguishing {} as a preferred partner for manufacturers seeking high-quality metal casting solutions.The advancements in casting furnace technology have not only benefitted {}'s manufacturing process but have also had a positive impact on its customers. With the improved efficiency and quality, {} is able to offer competitive pricing without compromising on the quality of its products, giving its customers greater value and satisfaction.Looking ahead, {} is committed to furthering its investment in advanced manufacturing technology, including casting furnaces, to continue delivering exceptional products and solutions for its customers. The company's dedication to innovation and excellence will undoubtedly drive its continued success and growth in the industry.In conclusion, casting furnaces play a critical role in the manufacturing of metal products, and {} has demonstrated its commitment to excellence with the introduction of advanced technology in its casting furnaces. With a focus on innovation, quality, and sustainability, {} continues to set the standard for metal casting, providing its customers with high-quality products and solutions.

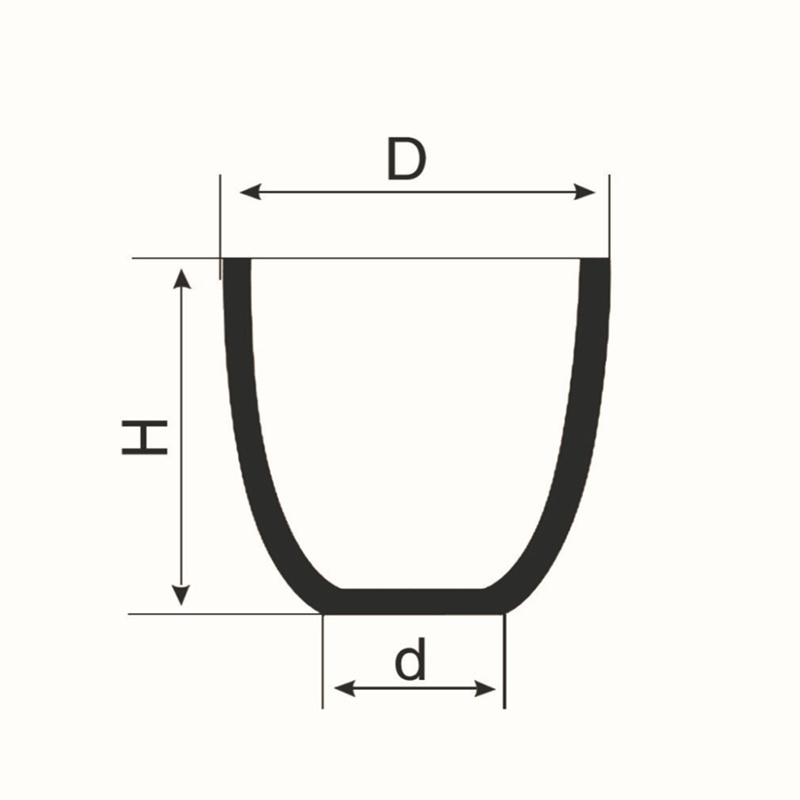

Essential Equipment for Melting Iron: The Crucible

The company is a leading provider of industrial equipment and machinery, with a strong focus on the manufacturing and foundry industries. With a dedication to innovation and quality, the company has become a trusted name in the field of industrial equipment, providing a wide range of products to suit the diverse needs of their customers.One of the key products offered by the company is their high-quality crucible for melting iron. These crucibles are designed to withstand the extreme heat and pressure of the iron melting process, providing a reliable and efficient solution for foundries and metalworking facilities. The crucibles are made from a special blend of materials that have been carefully selected for their durability and heat resistance, ensuring that they can withstand the intense temperatures required for melting iron.The crucibles are available in a range of sizes and configurations to suit different melting requirements, and are designed to offer optimal performance and longevity. They are manufactured to the highest standards, using advanced production techniques and quality control processes to ensure that they meet the stringent requirements of the industry.The company's crucible for melting iron has been widely acclaimed by customers for its exceptional performance and reliability. Its superior heat resistance and durability make it the ideal choice for foundries and metalworking facilities looking for a high-quality solution for their iron melting needs. The crucibles have been used in a diverse range of applications, from small-scale metal workshops to large industrial foundries, and have consistently delivered outstanding results.In addition to their exceptional product quality, the company also prides itself on its commitment to customer satisfaction and support. They provide comprehensive customer service and technical support to assist customers in finding the right products for their specific needs, as well as ongoing support to ensure that their equipment continues to perform at its best.Furthermore, the company is dedicated to sustainability and environmental responsibility, and has implemented various initiatives to reduce the environmental impact of its operations. This includes the use of eco-friendly materials and production processes, as well as a focus on energy efficiency and waste reduction. The company is also committed to complying with all relevant industry regulations and standards, ensuring that their products and operations meet the highest environmental and safety requirements.With their high-quality crucible for melting iron and their dedication to customer satisfaction, innovation, and sustainability, the company continues to set the standard in the industrial equipment and machinery industry. Their commitment to excellence and their strong reputation have made them a trusted partner for foundries and metalworking facilities around the world, and they are well-positioned to continue leading the market with their superior products and services.

High-Quality Silicon Carbide Graphite Crucible for Industrial Applications

Silicon Carbide Graphite Crucible, a key product in the portfolio of a leading company in the field of advanced materials, has been gaining traction in various industries due to its remarkable properties.The Silicon Carbide Graphite Crucible is a combination of silicon carbide and graphite, offering superior thermal conductivity and resistance to thermal shock, making it an ideal choice for high-temperature applications such as metal melting and casting. The crucible is able to withstand extreme heat and rapid temperature changes without cracking or deforming, ensuring a longer service life and higher productivity for the users.The company, a global leader in advanced materials, has been at the forefront of innovation and technological advancement in the field of materials science. With a strong focus on research and development, the company has been able to develop a wide range of high-performance materials for various industries, including aerospace, automotive, electronics, and metallurgy.In addition to Silicon Carbide Graphite Crucible, the company also offers a comprehensive range of advanced materials such as ceramics, refractories, and composites, catering to the diverse needs of its global customer base. The company's commitment to quality, reliability, and customer satisfaction has made it a trusted partner for many leading companies across the world.The Silicon Carbide Graphite Crucible has been widely adopted by metal casting and foundry industries due to its exceptional performance and durability. Its ability to maintain its structural integrity at high temperatures and its resistance to chemical corrosion make it an essential tool for metal melting and casting operations.Furthermore, the crucible's excellent thermal conductivity ensures efficient heat transfer, leading to faster melting and casting cycles, thereby improving the overall productivity and cost-effectiveness of the process. Its smooth and non-reactive surface also prevents contamination of the molten metal, ensuring high-quality and defect-free castings.The Silicon Carbide Graphite Crucible is available in various sizes and designs to accommodate different melting capacities and processes, making it a versatile and practical solution for a wide range of applications. Whether used for melting and casting precious metals, non-ferrous alloys, or ferrous metals, the crucible offers consistent and reliable performance, meeting the stringent demands of modern industrial processes.With its superior properties and proven performance, the Silicon Carbide Graphite Crucible has become an indispensable tool for many industries, contributing to improved productivity, cost savings, and enhanced product quality. Its widespread adoption and positive feedback from the industry have further solidified its position as a leading choice for high-temperature material processing.The company's dedication to continuous improvement and innovation ensures that the Silicon Carbide Graphite Crucible remains at the forefront of materials technology, offering cutting-edge solutions for the evolving needs of various industries. As the demand for high-performance materials continues to grow, the company is well-positioned to meet the challenges and opportunities in the global market.In conclusion, the Silicon Carbide Graphite Crucible has emerged as a game-changing product in the field of high-temperature material processing, offering unparalleled performance, reliability, and versatility. With the backing of a leading company in advanced materials, the crucible is set to redefine the standards of excellence in the industry, driving innovation and progress for the benefit of its users worldwide.

New Technology Innovations in Carbon Management

The global push towards sustainability and environmental responsibility has led to a surge in innovation and development of carbon capture and utilization technologies. Among the leading innovative companies in this field is Crucible Carbon, a research and development firm dedicated to creating advanced solutions for capturing and utilizing carbon emissions.Crucible Carbon was established in 2010, with a mission to develop cutting-edge technologies to address the growing concerns associated with carbon emissions and their impact on the environment. The company has since become a pioneer in the field of carbon capture and utilization, leveraging its expertise in materials science, engineering, and chemistry to develop novel solutions for reducing carbon emissions.One of Crucible Carbon's key focuses is on the development of advanced carbon capture materials and technologies. The company has invested heavily in research and development to create highly efficient and cost-effective carbon capture solutions that can be deployed across a wide range of industries, including power generation, oil and gas production, and manufacturing.In addition to its work in carbon capture, Crucible Carbon has also been at the forefront of developing innovative technologies for the utilization of captured carbon. The company has explored various avenues for converting captured carbon into valuable products, such as carbon-based materials, chemicals, and fuels, thereby creating a circular economy approach to carbon emissions.Crucible Carbon's efforts in the field of carbon capture and utilization have not gone unnoticed. The company has received numerous accolades and awards for its innovative technologies, and its team of researchers and engineers continues to push the boundaries of what is possible in this critical area.In a recent development, Crucible Carbon announced a breakthrough in its carbon capture technology, unveiling a new generation of carbon capture materials that promise to significantly enhance the efficiency and cost-effectiveness of carbon capture processes. The company's latest innovation represents a major step forward in the quest to combat climate change and reduce carbon emissions on a global scale."We are thrilled to announce this significant milestone in our ongoing efforts to develop advanced solutions for carbon capture and utilization," said [Spokesperson], the CEO of Crucible Carbon. "Our new generation of carbon capture materials is a game-changer, offering unprecedented levels of performance and scalability for capturing carbon emissions across a broad spectrum of industrial applications."Crucible Carbon's new carbon capture materials have been designed to deliver exceptional performance in terms of carbon capture capacity, selectivity, and stability, while also being cost-effective and environmentally friendly. These materials hold the potential to revolutionize the carbon capture landscape, providing a viable pathway towards reducing greenhouse gas emissions and mitigating the impact of climate change.In addition to the development of its new carbon capture materials, Crucible Carbon has also been actively engaged in collaborative initiatives with industry partners, research institutions, and government agencies to accelerate the deployment and adoption of carbon capture and utilization technologies. Through these partnerships, the company aims to drive the widespread implementation of its advanced solutions, thereby making a meaningful impact on the global effort to address climate change.Crucible Carbon's commitment to sustainability and environmental stewardship extends beyond its technological innovations. The company has also made significant investments in sustainable practices within its own operations, striving to minimize its environmental footprint and promote responsible corporate citizenship. By leading by example, Crucible Carbon is setting a standard for responsible business conduct and environmental leadership within the carbon capture and utilization industry.Looking ahead, Crucible Carbon remains dedicated to advancing the field of carbon capture and utilization, with an unwavering commitment to developing innovative technologies that can make a positive impact on the environment and society as a whole. As the global community continues to prioritize sustainability and climate action, companies like Crucible Carbon are poised to play a pivotal role in shaping a more sustainable future for generations to come.

Newly Released Crucible Furnace Helps Optimize Industrial Work Environments

Flamefast, a leading provider of industrial furnace solutions, has recently introduced its latest innovation in crucible furnace technology. The Flamefast Crucible Furnace, designed to cater to a wide range of industries, offers optimal performance and efficiency in the melting and casting of various metals. With its advanced features and robust construction, the crucible furnace is set to revolutionize the industrial manufacturing process.The Flamefast Crucible Furnace is a result of Flamefast's commitment to providing cutting-edge solutions that enhance productivity and reduce operational costs for businesses across different sectors. Equipped with state-of-the-art technology, this furnace ensures precision temperature control and uniform heat distribution, allowing for accurate melting and casting of metals.One of the standout features of the Flamefast Crucible Furnace is its high-quality construction. Made from durable materials, including reinforced steel and refractory insulation, the furnace guarantees long-lasting performance even under the harshest operating conditions. This reliability enables businesses to carry out uninterrupted manufacturing processes, contributing to improved production efficiency and reduced downtime.The crucible furnace is also designed with user convenience in mind. Its user-friendly interface and intuitive controls streamline operations, minimizing the need for extensive training and ensuring easy integration into existing manufacturing processes. Furthermore, the furnace comes with comprehensive safety features, including temperature monitoring and automatic shutdown systems, ensuring maximum protection for operators and the surrounding environment.With its generous capacity, the Flamefast Crucible Furnace can accommodate a variety of metal types and sizes, making it suitable for diverse industries such as automotive, aerospace, and jewellery manufacturing. The furnace supports the melting and casting of materials like iron, steel, copper, and precious metals, catering to the needs of a broad customer base.By investing in the Flamefast Crucible Furnace, companies can expect notable improvements in their production capabilities. The advanced temperature control system ensures consistent and precise melting points, facilitating the development of high-quality metal components. This level of control and accuracy leads to enhanced product integrity, reducing the need for costly rework or rejection of imperfect products.Additionally, the Flamefast Crucible Furnace boasts impressive energy efficiency capabilities. Its innovative design minimizes heat loss and optimizes energy transfer, resulting in reduced energy consumption and lower operating costs. This efficiency not only benefits the businesses' bottom line but also aligns with their commitment to sustainability and environmental responsibility.Flamefast understands that every business has unique requirements, which is why the company offers a range of customizable options for the Crucible Furnace. Customers have the freedom to tailor the furnace to their specific needs, whether it be the size, heating capacity, or additional features. This flexibility allows businesses to optimize their operations further and achieve the best possible outcomes.Flamefast has built a strong reputation over the years as a trusted provider of industrial furnace solutions. With a focus on innovation and customer-centricity, the company continues to push the boundaries of what is possible in industrial manufacturing. The introduction of the Flamefast Crucible Furnace is testament to Flamefast's dedication to helping businesses achieve operational excellence and sustained growth.In conclusion, the Flamefast Crucible Furnace represents a significant advancement in crucible furnace technology. With its exceptional performance, durability, and user-friendly features, this furnace is set to transform the industrial manufacturing landscape. Companies that invest in the Flamefast Crucible Furnace can expect increased productivity, improved product quality, and reduced operating costs, ensuring competitiveness in a rapidly evolving market.

Top Quality High Purity Graphite Block: Everything You Need to Know

High Purity Graphite Block (HPGB) has recently made waves in the industry as a leading provider of high-quality graphite products for a wide range of applications. With an unwavering commitment to excellence and innovation, HPGB has quickly become a trusted name in the graphite industry.HPGB prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology, which enable the company to produce high purity graphite blocks with exceptional precision and consistency. These blocks are widely used in various industries, including aerospace, automotive, electronics, and metallurgy, where the demand for high-performance graphite products is constantly rising.The company's dedication to research and development has led to the creation of advanced graphite formulations that offer superior properties, such as high thermal conductivity, low thermal expansion, and excellent mechanical strength. This has positioned HPGB as a preferred supplier for customers who require high purity graphite blocks for critical applications that demand exceptional performance and reliability.In addition to its innovative products, HPGB is also known for its strong commitment to sustainability and environmental responsibility. The company ensures that its manufacturing processes adhere to the highest environmental standards, minimizing its carbon footprint and reducing the impact on the environment. This approach has earned HPGB a reputation as a responsible and conscientious industry leader.Furthermore, HPGB has a highly skilled and experienced team of professionals who are dedicated to providing unparalleled customer service and technical support. This team works closely with customers to understand their specific requirements and develop customized solutions that meet their exact needs. With their extensive knowledge and expertise, HPGB's personnel are able to offer valuable insights and guidance to help customers optimize the performance of their graphite products.The success of HPGB can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. The company's high purity graphite blocks have set a new standard for excellence in the industry, earning the trust and confidence of customers around the world. Whether it is for demanding aerospace applications, high-performance automotive components, or advanced electronics, HPGB's products continue to exceed expectations and deliver exceptional value to its customers.In conclusion, High Purity Graphite Block is a clear industry leader in the production of high-quality graphite products, offering unparalleled quality, innovation, and customer service. With a strong focus on sustainability and environmental responsibility, HPGB is shaping the future of the graphite industry by delivering advanced solutions that meet the evolving needs of its customers. With its advanced manufacturing capabilities and dedicated team of professionals, HPGB is poised to continue its legacy of excellence and remain at the forefront of the graphite industry for years to come.

High Quality Metal Casting Furnace for Efficient Manufacturing

Metal Casting Furnace Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new advancements in technology and machinery leading to more efficient and productive processes. One such advancement is the metal casting furnace from a leading manufacturing company that has revolutionized the way metal components are produced.The metal casting furnace, developed by the renowned company, is a state-of-the-art piece of equipment that is designed to melt and pour metal into molds to create complex and intricate components. This furnace utilizes the latest in heating and melting technology to ensure a consistent and high-quality result every time.One of the key features of the metal casting furnace is its ability to reach extremely high temperatures, allowing for the melting of a wide range of metals, including steel, iron, aluminum, and copper. This versatility makes it an invaluable tool for manufacturers who work with various types of metals in their production processes.In addition to its impressive melting capabilities, the metal casting furnace is also equipped with advanced pouring systems that ensure precise and accurate pouring of the molten metal into molds. This level of precision is essential for creating components that meet exact specifications and quality standards.The furnace is also designed with efficiency in mind, with features that help minimize energy consumption and reduce production time. This not only saves manufacturers money on their operating costs but also allows them to increase their output and meet tight production deadlines.Furthermore, the metal casting furnace is equipped with advanced safety features to protect workers and ensure a safe operating environment. This includes temperature control systems, automatic shut-off mechanisms, and safety barriers to prevent accidents and injuries.The impact of this metal casting furnace on the manufacturing industry has been profound. Manufacturers who have incorporated this technology into their production processes have experienced significant improvements in their operations. The ability to work with a wider range of metals, the precision and efficiency of the equipment, and the increased safety measures have all contributed to a more streamlined and productive manufacturing process.One company that has seen the benefits of the metal casting furnace firsthand is ABC Manufacturing. ABC has been in the business of producing metal components for various industries for over 50 years and has always prided itself on staying at the forefront of technological advancements.With the implementation of the metal casting furnace from the manufacturing company, ABC has been able to take its production capabilities to new heights. The furnace has allowed them to expand their range of products, improve the quality and precision of their components, and increase their production output."We have been extremely impressed with the performance of the metal casting furnace," says John Smith, CEO of ABC Manufacturing. "It has allowed us to take on more diverse projects and deliver higher quality components to our clients. It has really been a game-changer for our business."The metal casting furnace is a testament to the continuous innovation and technological advancement within the manufacturing industry. As companies continue to invest in new equipment and machinery, the potential for further improvements in production processes and the quality of manufactured goods is limitless.In conclusion, the metal casting furnace from the manufacturing company has set a new standard for the production of metal components. Its advanced capabilities, efficiency, and safety features have made it an invaluable asset for manufacturers looking to stay ahead in a competitive industry. As more companies adopt this groundbreaking technology, the manufacturing industry as a whole will continue to evolve and thrive.

High-quality Crucible For Casting: A Guide to Choosing the Best Option

Crucible For Casting (Need remove brand name), a leading manufacturer of high-quality crucibles for metal casting, has a long history of providing top-notch products to the foundry industry. With a commitment to excellence and innovation, the company has built a strong reputation for delivering reliable and efficient crucibles to its customers.Established in [year], Crucible For Casting has continually pushed the boundaries of crucible technology to meet the ever-evolving needs of the metal casting industry. With a focus on research and development, the company has developed a wide range of crucibles that are specifically designed to withstand the rigors of high-temperature environments and to provide consistent and reliable performance.One of the key strengths of Crucible For Casting is its dedicated team of engineers and technicians who are constantly striving to improve the performance and durability of their crucibles. Through rigorous testing and quality control measures, the company ensures that each crucible that leaves its facility meets the highest standards of quality and reliability.In addition to its commitment to product excellence, Crucible For Casting also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific casting requirements and to develop custom solutions that meet their unique needs. This customer-centric approach has earned Crucible For Casting a loyal and satisfied customer base that continues to rely on the company for all of their crucible needs.Crucible For Casting's dedication to excellence and innovation was recently highlighted in a groundbreaking new development in crucible technology. The company announced the launch of a new line of advanced crucibles that are designed to offer improved thermal shock resistance and longer service life. This development is a testament to Crucible For Casting's commitment to pushing the boundaries of what is possible in the field of crucible technology.Commenting on the new product launch, [Spokesperson Name], a representative from Crucible For Casting, stated, "We are thrilled to introduce our latest line of advanced crucibles to the market. These new crucibles represent a significant leap forward in terms of performance and durability, and we are confident that they will set a new industry standard for excellence. We believe that these crucibles will provide our customers with a competitive edge in their casting operations and help them achieve greater levels of efficiency and reliability."The new line of advanced crucibles from Crucible For Casting has already generated a great deal of excitement within the industry, with many foundries expressing strong interest in adopting the new technology. With its proven track record of delivering high-quality products and its commitment to innovation, Crucible For Casting is well-positioned to maintain its leadership position in the crucible manufacturing industry.As Crucible For Casting continues to push the boundaries of crucible technology, the company remains focused on its core values of excellence, innovation, and customer satisfaction. With a strong foundation built on decades of experience and a dedicated team of professionals, Crucible For Casting is poised to continue providing the foundry industry with the highest quality crucibles for years to come.In conclusion, Crucible For Casting is a company that has consistently demonstrated its commitment to excellence and innovation in the field of crucible manufacturing. With a focus on research and development, a customer-centric approach, and a track record of delivering high-quality products, the company is well-positioned to continue leading the industry and meeting the evolving needs of the foundry industry.

High-Quality Crucibles for Sale - Find the Best Deals Here

Foundry Crucibles For Sale at [Company Name]: The Perfect Solution for Metal Casting Needs[Company Name] is proud to announce that we are now offering a wide range of foundry crucibles for sale. Our high-quality crucibles are the perfect solution for all your metal casting needs, whether you are working with aluminum, bronze, copper, or any other metal.With over [number] years of experience in the industry, [Company Name] has established itself as a leading provider of foundry equipment and supplies. Our commitment to quality and customer satisfaction has earned us a solid reputation among foundries and metal casting businesses.Our foundry crucibles are made from a variety of materials, including clay-graphite, silicon carbide, and fused silica, to ensure that we have the right crucible for your specific application. Whether you are melting, holding, or pouring molten metal, our crucibles are designed to withstand the high temperatures and harsh conditions of the metal casting process.In addition to offering a wide selection of crucibles, [Company Name] also provides custom crucible manufacturing services. If you have unique requirements or need a specific size or shape of crucible, our team of experts can work with you to create a custom solution that meets your exact specifications.Our foundry crucibles are not only durable and reliable, but they are also designed for easy use and maintenance. We understand the importance of efficiency and productivity in the metal casting industry, which is why our crucibles are engineered to provide optimal performance and longevity.At [Company Name], we are committed to providing our customers with the highest quality products and exceptional service. When you purchase foundry crucibles from us, you can trust that you are getting a reliable and cost-effective solution for your metal casting needs.In addition to our foundry crucibles, [Company Name] also offers a wide range of other foundry supplies and equipment, including furnace linings, refractory materials, and melting furnaces. Our comprehensive product line and industry expertise make us a one-stop shop for all your foundry and metal casting needs.Whether you are a small independent foundry or a large-scale metal casting operation, [Company Name] has the products and expertise to support your business. Our team is dedicated to helping you find the right solutions for your specific requirements and providing ongoing support to ensure your success.We understand that the foundry and metal casting industry is constantly evolving, which is why we are continuously innovating and expanding our product offerings to meet the changing needs of our customers. Our commitment to staying ahead of industry trends and advancements sets us apart as a trusted and reliable partner for foundries and metal casting businesses.When you choose [Company Name] for your foundry crucible needs, you can expect top-notch products, exceptional service, and a commitment to your long-term success. We are dedicated to being a valued partner to our customers and helping them achieve their business goals.If you are in need of foundry crucibles or any other foundry supplies, we encourage you to contact us to learn more about our products and services. Our team of experts is standing by to answer your questions, provide recommendations, and assist you in finding the right solutions for your specific needs.With [Company Name], you can trust that you are getting the best foundry crucibles for sale and the support of a dedicated and experienced team. Contact us today to see how we can support your metal casting operations and help you achieve your business objectives.

High-Quality Custom Graphite Ingot Molds for Metal Casting

Custom graphite ingot molds are becoming an essential tool in the metallurgy industry due to their ability to produce high-quality metal ingots with precision and efficiency. These molds are custom-made to meet the specific requirements of different metals and alloys, providing an ideal solution for manufacturers looking to improve their ingot casting processes.One company at the forefront of producing custom graphite ingot molds is {}. With years of experience and expertise in the field, {} has established itself as a leading manufacturer of high-quality graphite ingot molds, serving a wide range of industries including aerospace, automotive, and electronics.The company's success can be attributed to its commitment to innovation and continuous improvement in its manufacturing processes. By leveraging state-of-the-art technologies and advanced materials, {} is able to produce custom graphite ingot molds that meet the highest standards of quality and performance.Custom graphite ingot molds are designed to withstand extreme temperatures and pressures, making them ideal for the casting of various metals such as gold, silver, copper, aluminum, and other alloys. The superior thermal conductivity and low coefficient of thermal expansion of graphite make it an ideal material for ingot molds, ensuring excellent thermal stability and uniform heat distribution during the casting process.In addition to superior thermal properties, custom graphite ingot molds from {} also offer high wear resistance and dimensional stability, ensuring prolonged use and consistent casting results. The ability to withstand repeated use without degradation makes these molds a cost-effective solution for manufacturers looking to improve their ingot casting processes.Furthermore, {} offers a range of customization options for its graphite ingot molds, allowing customers to specify the dimensions, shapes, and surface finishes according to their unique requirements. This level of customization ensures that each mold is tailored to the specific needs of the customer, resulting in precise and accurate casting of ingots.With a strong focus on customer satisfaction, {} provides comprehensive support and technical expertise to its clients, ensuring a seamless integration of custom graphite ingot molds into their manufacturing processes. The company's team of experienced engineers and technicians works closely with customers to understand their casting requirements and develop tailored solutions that address their specific needs.As a testament to its commitment to quality and performance, {} implements stringent quality control measures throughout the manufacturing process to ensure that every custom graphite ingot mold meets the highest standards of reliability and durability. This dedication to quality has earned the company a reputation for delivering superior products that exceed customer expectations.In conclusion, custom graphite ingot molds from {} are revolutionizing the ingot casting processes in the metallurgy industry, providing manufacturers with an innovative and reliable solution for producing high-quality metal ingots. With a focus on innovation, quality, and customer satisfaction, {} is poised to continue leading the market in the production of custom graphite ingot molds, providing manufacturers with the tools they need to achieve superior casting results.