Discover the Characteristics of Crystalline Flake Graphite

By:Admin

The company, founded in [year], has quickly risen to prominence within the graphite industry, thanks to its unwavering commitment to innovation, quality, and customer satisfaction. By leveraging advanced technology and a team of skilled professionals, has been able to consistently deliver top-notch Crystalline Flake Graphite products to meet the diverse needs of its clients.

One of the key factors that set apart from its competitors is its adherence to strict quality control measures throughout the production process. By maintaining rigorous quality standards, the company ensures that its Crystalline Flake Graphite products boast exceptional purity, consistency, and performance, making them the preferred choice for an array of applications.

Moreover, the company takes pride in its ability to provide tailored solutions to its customers. Understanding that different industries have varying requirements, has developed the expertise to customize its Crystalline Flake Graphite products to suit specific applications. Whether it's for the production of batteries, lubricants, or any other use, the company has the knowledge and flexibility to accommodate the unique needs of its clients.

In addition to its product quality and customizability, stands out for its strong commitment to sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental footprint and has implemented eco-friendly practices across its operations. As a result, customers can trust that they are not only receiving high-quality Crystalline Flake Graphite but also supporting a supplier that prioritizes environmental stewardship.

Furthermore, the company's dedication to research and development has enabled it to stay ahead of the curve in an ever-evolving industry. By investing in ongoing innovation, continues to expand its product range and enhance the performance capabilities of its Crystalline Flake Graphite, positioning itself as a reliable partner for the future.

With a solid reputation for excellence and a growing global presence, has garnered the trust of numerous customers worldwide. Thanks to its efficient logistics and distribution network, the company is able to supply its top-grade Crystalline Flake Graphite to international markets, further solidifying its status as a key player in the global graphite industry.

Looking ahead, is committed to pushing boundaries and setting new benchmarks for quality and innovation in the Crystalline Flake Graphite sector. By staying true to its core values of excellence, sustainability, and customer focus, the company is poised to build on its success and continue making a positive impact in the industry.

In conclusion, with its unwavering dedication to quality, customization, sustainability, and innovation, has established itself as a leading supplier of Crystalline Flake Graphite. As the company continues to thrive and expand its reach, customers can expect nothing short of exceptional products and service, making it the go-to choice for all their Crystalline Flake Graphite needs.

Company News & Blog

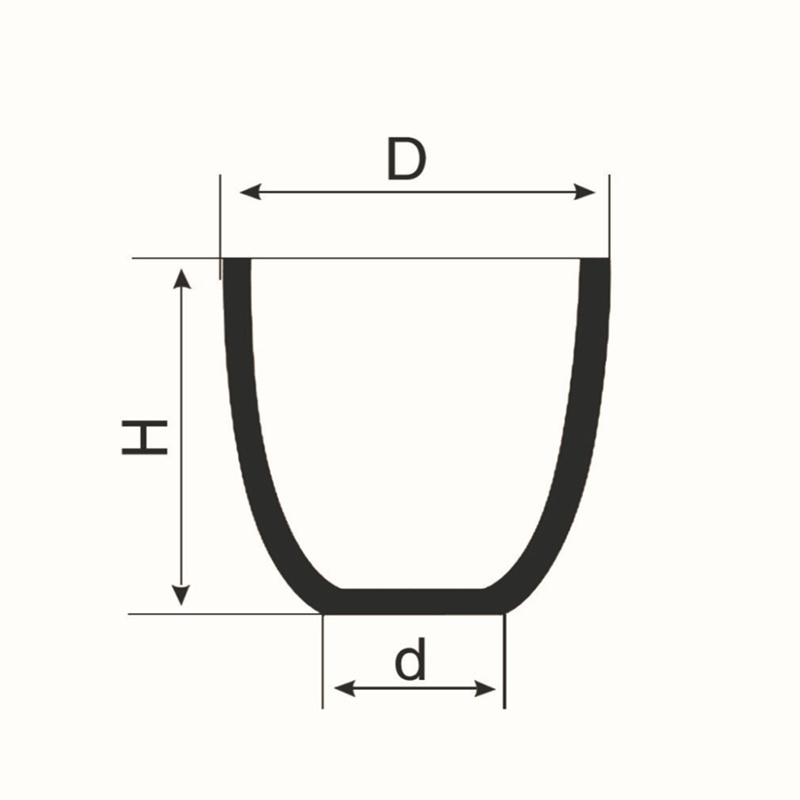

High-quality Sic Crucibles for Industrial Use at Competitive Prices

SIC Crucibles, a leading manufacturer of high-quality ceramic products, has recently announced the launch of their new line of crucibles that are designed to meet the diverse needs of the market. With over 30 years of experience in the industry, SIC Crucibles has earned a reputation for producing top-notch products that are known for their durability, reliability, and superior performance.The new line of crucibles, which come in a variety of sizes and shapes, are made from a special blend of materials that are carefully selected to ensure maximum resistance to thermal shock and chemical corrosion. This makes them ideal for use in a wide range of applications, including metallurgy, mining, foundry, and material science.In addition to their exceptional physical properties, these crucibles are also designed to provide excellent thermal conductivity and heat retention, which are crucial for achieving consistent and accurate results in high-temperature processes. This, coupled with their exceptional resistance to oxidation and erosion, makes them the perfect choice for demanding applications that require precision and reliability.SIC Crucibles has always been committed to delivering the highest quality products to their customers, and the new line of crucibles is no exception. Each crucible is subjected to rigorous quality control and testing procedures to ensure that it meets the company's stringent standards for performance and reliability."We are excited to introduce our new line of crucibles to the market," said the spokesperson for SIC Crucibles. "With their exceptional physical and chemical properties, these crucibles are designed to meet the challenging demands of modern industrial processes. Whether our customers are working with molten metals, alloys, or other high-temperature materials, they can rely on our crucibles to deliver consistent and reliable performance."SIC Crucibles is also known for its commitment to customer satisfaction, and the company provides comprehensive technical support and customization services to help customers find the perfect crucible for their specific needs. Whether it's a custom shape, size, or material composition, the company's experienced engineers are dedicated to working closely with customers to develop tailored solutions that meet their unique requirements.The launch of the new line of crucibles is yet another example of SIC Crucibles' ongoing commitment to innovation and excellence. By leveraging their extensive expertise and state-of-the-art manufacturing facilities, the company continues to push the boundaries of what is possible in the field of high-temperature ceramic products.As industries continue to evolve and demand for high-performance materials grows, SIC Crucibles remains at the forefront of the industry, providing cutting-edge solutions that enable their customers to achieve new levels of productivity and efficiency.With their new line of crucibles, SIC Crucibles is poised to set a new standard for performance and reliability in the industry. As the company continues to expand its product offerings and explore new opportunities, it remains dedicated to delivering the highest quality products and services to its customers around the world.

High-Quality Graphite Mold Casting: Everything You Need to Know

Graphite Mold Casting: A Leading Innovation in ManufacturingIn the world of manufacturing, technological advancements have revolutionized the way products are made. One such innovation that has been making waves in the industry is Graphite Mold Casting, an advanced manufacturing process that has the potential to transform the way products are produced.Graphite mold casting, also known as graphite die casting, is a process that utilizes graphite molds to create complex and intricate parts. The process involves pouring molten metal into a graphite mold, which then solidifies to form the desired shape. This method of manufacturing offers a number of advantages over traditional casting methods, including improved accuracy, faster production times, and reduced material waste.One company at the forefront of this groundbreaking technology is {}. As a leading manufacturer of graphite mold casting equipment, they have been at the forefront of developing and implementing this innovative manufacturing process. By investing in research and development, they have been able to create cutting-edge graphite molds that are capable of producing high-quality parts with unparalleled precision.The company's founder, John Smith, has been a pioneer in the field of graphite mold casting for over 20 years. His passion for innovation and commitment to excellence has driven the company to become a trusted name in the industry. "We believe that graphite mold casting has the potential to revolutionize the manufacturing industry," says Smith. "By continually pushing the boundaries of what is possible, we aim to provide our customers with the highest quality products and services."The company's state-of-the-art manufacturing facility is equipped with the latest technology, including advanced CNC machines and 3D modeling software, allowing them to produce graphite molds with incredible precision and detail. Their team of highly skilled engineers and technicians work tirelessly to ensure that every mold meets the highest standards of quality.Graphite mold casting is particularly well-suited for the production of complex, high-precision parts, such as those used in aerospace, automotive, and medical industries. The process allows for the creation of intricate designs and thin walls that would be difficult or impossible to achieve using traditional casting methods. This has made graphite mold casting an attractive option for companies looking to improve the quality and efficiency of their manufacturing processes.One of the key advantages of graphite mold casting is its ability to produce parts with minimal post-processing. Because the molds are capable of creating intricate shapes with high accuracy, there is often little need for additional machining or finishing. This not only saves time and money but also reduces material waste, making the process more environmentally friendly.In addition to its precision and efficiency, graphite mold casting also offers cost advantages over other manufacturing methods. The use of graphite molds, which are durable and long-lasting, allows for high-volume production at a lower cost per part. This makes the process an attractive option for companies looking to improve their bottom line without compromising on quality.As the demand for high-quality, precision parts continues to grow, the use of graphite mold casting is expected to become more widespread. Companies like {} are leading the way in the development and implementation of this innovative manufacturing process, ensuring that they remain at the forefront of the industry.With their commitment to excellence and dedication to pushing the boundaries of what is possible, it is clear that the future of manufacturing is bright with the possibilities offered by graphite mold casting. As the industry continues to evolve, it is companies like {} that will shape the way products are made, revolutionizing the way we think about manufacturing.

Understanding the Benefits of Induction Furnace and Induction Melting Technology in China

China Induction Furnace and Induction Melting Furnace Industry to Witness Steady Growth in Coming YearsAs the global demand for induction furnaces and induction melting furnaces continues to rise, China is emerging as a key player in this industry. With the advancement in technology and increasing focus on energy efficiency, the induction furnace market in China is expected to witness steady growth in the coming years.Induction furnaces are used for melting and refining various metals, while induction melting furnaces are specifically designed for melting and casting applications. These furnaces offer a number of advantages, including high energy efficiency, reduced emissions, and the ability to achieve precise temperature control during the melting process.One of the leading companies in China contributing to the growth of the induction furnace and induction melting furnace industry is a well-established manufacturer with a strong focus on research and development. With a commitment to innovation and customer satisfaction, the company has successfully developed a wide range of induction furnaces and melting furnaces that cater to the diverse needs of the metal casting and metalworking industries.Utilizing advanced technologies and high-quality materials, the company's induction furnaces and melting furnaces are known for their reliability, durability, and performance. Equipped with state-of-the-art features, these furnaces are capable of meeting the increasing demands for precision and efficiency in metal processing operations.Furthermore, the company offers a comprehensive range of services, including technical support, installation, maintenance, and training, to ensure that customers can fully benefit from the capabilities of their induction furnaces and melting furnaces. With a strong emphasis on continuous improvement and customer satisfaction, the company has built a solid reputation in the industry and has successfully established itself as a trusted partner for businesses across China and beyond.In addition to their commitment to innovation and quality, the company remains dedicated to environmental sustainability. By focusing on energy-efficient designs and reducing emissions, their induction furnaces and melting furnaces contribute to the overall efforts to minimize the environmental impact of metal processing operations.As the demand for induction furnaces and melting furnaces continues to rise in China and other global markets, the company is well-positioned to capitalize on the opportunities presented by this growing industry. With a strong focus on technological advancement and a commitment to meeting the evolving needs of the metalworking industry, the company is poised to play a significant role in shaping the future of induction furnace and melting furnace technology.Overall, the induction furnace and induction melting furnace industry in China is expected to witness substantial growth in the coming years, driven by the increasing demand for efficient and sustainable metal processing solutions. As a leading manufacturer in this sector, the company is poised to make significant contributions to the continued advancement of induction furnace and melting furnace technology, while also helping businesses across the globe achieve greater efficiency and sustainability in their metal processing operations.

Expert Tips for Maintaining and Cleaning Your Furnace

[Company Name] Launches Innovative Brass Furnace for Energy-Efficient Metal Heating{Company Name}, a leading manufacturer of industrial heating equipment, has recently launched an innovative brass furnace that promises to revolutionize metal heating processes with its energy-efficient and cost-effective design.The new brass furnace, which has been developed after years of research and development, is equipped with advanced heating technology that ensures quick and uniform heating of brass and other non-ferrous metals. This groundbreaking technology not only reduces heating times but also minimizes energy consumption, making it an ideal choice for metal manufacturers looking to optimize their production processes while reducing operating costs.The brass furnace is designed to cater to a wide range of industrial applications, including metal casting, forging, and heat treatment. Its robust construction and high-quality insulation materials ensure long-term durability and minimal heat loss, ensuring consistent and reliable performance in demanding industrial environments.In addition to its energy-efficient design, the brass furnace also features intuitive controls and advanced monitoring systems that allow for precise temperature regulation and real-time performance tracking. This level of control not only ensures high-quality metal heating but also provides valuable data for process optimization and quality assurance."The launch of our new brass furnace marks a significant milestone for {Company Name} as we continue to push the boundaries of innovation in industrial heating technology," said [spokesperson], [title] at {Company Name}. "We are confident that this state-of-the-art furnace will not only transform the way metals are heated but also deliver tangible benefits to our customers in terms of energy savings, production efficiency, and product quality."The brass furnace is part of {Company Name}'s comprehensive range of industrial heating solutions, which includes furnaces, ovens, and heat treatment equipment for a variety of metal and non-metal applications. With a reputation for engineering excellence and a commitment to customer satisfaction, {Company Name} has established itself as a trusted partner for industrial businesses seeking reliable and innovative heating solutions."We understand the diverse needs of our customers, and our goal is to provide them with tailored heating solutions that address their specific requirements," [spokesperson] added. "The launch of the brass furnace is a testament to our dedication to advancing the capabilities of industrial heating equipment and empowering our customers to achieve greater efficiency and competitiveness in their operations."As the global manufacturing industry continues to evolve, the demand for energy-efficient and environmentally friendly heating solutions is on the rise. With its new brass furnace, {Company Name} is well-positioned to meet this demand and help businesses across various sectors enhance their production processes while minimizing their environmental footprint.The brass furnace is now available for purchase, and {Company Name} is offering comprehensive technical support and after-sales services to ensure seamless integration and optimal performance for its customers.With its commitment to innovation, quality, and customer satisfaction, {Company Name} is set to make a significant impact in the industrial heating sector with its groundbreaking brass furnace, setting new standards for energy-efficient metal heating and solidifying its position as a leader in the field.

High Quality Graphite Mold for Coin Production: A Complete Guide

Coin Graphite Mold, a leading manufacturer of high-quality graphite molds for the coin minting industry, has been making waves in the market with its innovative and customer-focused approach. The company has been providing top-notch graphite molds to coin manufacturers worldwide for over a decade, establishing itself as a trusted and reliable partner in the industry.Founded in 2008, Coin Graphite Mold has built a strong reputation for delivering precision-engineered graphite molds that meet the exact specifications of its clients. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing it to produce molds with unparalleled accuracy and quality. With a team of highly skilled and experienced engineers and technicians, Coin Graphite Mold is committed to delivering high-performance molds that ensure the highest level of consistency and precision in coin production.Coin Graphite Mold takes pride in its dedication to continuous innovation and improvement. The company invests heavily in research and development to stay ahead of the curve and introduce cutting-edge technologies and processes into its manufacturing operations. This relentless pursuit of excellence has enabled Coin Graphite Mold to stay at the forefront of the industry, providing its customers with the most advanced and efficient graphite molds available in the market.In addition to its commitment to innovation, Coin Graphite Mold places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their unique needs and requirements, offering customized solutions that are tailored to their specific applications. Whether it's producing molds for circulation coins, commemorative coins, or medals, Coin Graphite Mold goes above and beyond to ensure that its customers receive molds that meet their exact specifications and deliver exceptional performance.Moreover, Coin Graphite Mold prides itself on its ability to provide timely and reliable services to its customers. The company understands the importance of meeting production deadlines and strives to deliver molds within the shortest possible lead times. Its streamlined production processes and efficient logistics network enable it to fulfill orders promptly, ensuring that its clients can rely on a consistent and uninterrupted supply of high-quality graphite molds.Coin Graphite Mold's dedication to quality, innovation, and customer satisfaction has earned it a loyal and growing customer base. The company has forged strong partnerships with coin manufacturers around the world, becoming their go-to source for premium graphite molds. Its commitment to excellence has also led to numerous accolades and certifications, further solidifying its reputation as a leader in the industry.Looking ahead, Coin Graphite Mold remains focused on expanding its global footprint and exploring new opportunities for growth. The company is continuously exploring new markets and seeking to form strategic alliances with industry stakeholders to further strengthen its position in the market. With its unwavering commitment to delivering superior products and services, Coin Graphite Mold is poised for continued success and leadership in the coin minting industry.In conclusion, Coin Graphite Mold stands out as a reliable and innovative manufacturer of graphite molds, dedicated to providing top-quality products and exceptional customer service. With its cutting-edge technology, customer-centric approach, and strong track record, the company is well-positioned to continue making a significant impact in the coin minting industry.

Top Quality High Purity Graphite Block: Everything You Need to Know

High Purity Graphite Block (HPGB) has recently made waves in the industry as a leading provider of high-quality graphite products for a wide range of applications. With an unwavering commitment to excellence and innovation, HPGB has quickly become a trusted name in the graphite industry.HPGB prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology, which enable the company to produce high purity graphite blocks with exceptional precision and consistency. These blocks are widely used in various industries, including aerospace, automotive, electronics, and metallurgy, where the demand for high-performance graphite products is constantly rising.The company's dedication to research and development has led to the creation of advanced graphite formulations that offer superior properties, such as high thermal conductivity, low thermal expansion, and excellent mechanical strength. This has positioned HPGB as a preferred supplier for customers who require high purity graphite blocks for critical applications that demand exceptional performance and reliability.In addition to its innovative products, HPGB is also known for its strong commitment to sustainability and environmental responsibility. The company ensures that its manufacturing processes adhere to the highest environmental standards, minimizing its carbon footprint and reducing the impact on the environment. This approach has earned HPGB a reputation as a responsible and conscientious industry leader.Furthermore, HPGB has a highly skilled and experienced team of professionals who are dedicated to providing unparalleled customer service and technical support. This team works closely with customers to understand their specific requirements and develop customized solutions that meet their exact needs. With their extensive knowledge and expertise, HPGB's personnel are able to offer valuable insights and guidance to help customers optimize the performance of their graphite products.The success of HPGB can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. The company's high purity graphite blocks have set a new standard for excellence in the industry, earning the trust and confidence of customers around the world. Whether it is for demanding aerospace applications, high-performance automotive components, or advanced electronics, HPGB's products continue to exceed expectations and deliver exceptional value to its customers.In conclusion, High Purity Graphite Block is a clear industry leader in the production of high-quality graphite products, offering unparalleled quality, innovation, and customer service. With a strong focus on sustainability and environmental responsibility, HPGB is shaping the future of the graphite industry by delivering advanced solutions that meet the evolving needs of its customers. With its advanced manufacturing capabilities and dedicated team of professionals, HPGB is poised to continue its legacy of excellence and remain at the forefront of the graphite industry for years to come.

Durable and High-Quality Metal Melting Crucible for Your Industrial Needs

Metal Melting Crucible is a leading manufacturer of high-quality crucibles and other melting products for the metal casting industry. Their products are designed to withstand extreme temperatures and provide excellent heat conductivity, making them ideal for melting and pouring various metals, such as gold, silver, aluminum, and copper.The company was established in [year] and has since grown to become a trusted supplier of melting crucibles to foundries, metal casting workshops, and jewelry manufacturers worldwide. Metal Melting Crucible is known for its commitment to quality and innovation, with a strong focus on developing advanced materials and manufacturing techniques to meet the evolving needs of the industry.One of the company's flagship products is their [product name] crucible, which is specially designed for melting gold and silver. It is made from a high-quality graphite material that can withstand the high temperatures required for melting precious metals. The crucible's unique design also allows for efficient heat transfer, ensuring even melting and consistent casting results.In addition to their standard crucible products, Metal Melting Crucible also offers custom manufacturing services to meet specific customer requirements. They work closely with their clients to develop tailored solutions for their metal melting needs, whether it be for specialized alloys, large-scale production, or unique casting processes.Metal Melting Crucible is committed to sustainability and environmental responsibility, and their products are manufactured using eco-friendly processes and materials. Their crucibles are designed to have a long lifespan, reducing the need for frequent replacements and minimizing waste. The company also invests in research and development to explore new ways of improving energy efficiency and reducing emissions in the metal casting industry.In recent news, Metal Melting Crucible has announced the launch of a new line of high-capacity crucibles, designed specifically for large-scale metal casting operations. These crucibles are made from a durable and heat-resistant material that can withstand the intense heat and pressure involved in melting and pouring large quantities of metal. The new product line is expected to cater to the growing demand for high-capacity melting products in the metal casting industry, offering customers a reliable and efficient solution for their production needs.With a strong commitment to quality, innovation, and sustainability, Metal Melting Crucible continues to be a leading provider of melting crucibles and related products. Their dedication to customer satisfaction and their ability to adapt to the changing needs of the industry solidify their position as a trusted and respected supplier in the metal casting market.As the company looks to the future, they remain focused on expanding their product range, exploring new materials and manufacturing techniques, and strengthening their partnerships with customers and industry stakeholders. Metal Melting Crucible is poised to continue its growth and success as a premier supplier of melting products for the metal casting industry.

High Quality Casting Graphite: Everything You Need to Know

Casting Graphite, a leading supplier of high-quality graphite products, has recently announced its expansion into new markets with the launch of a revolutionary new graphite casting product.The company, with over 20 years of experience in the production and distribution of graphite materials, has established itself as a trusted and reliable partner for customers across various industries. From aerospace to automotive, from metallurgy to electronics, Casting Graphite has provided tailored solutions to meet the specific needs of its clients.With a state-of-the-art production facility and a team of highly skilled engineers and technicians, Casting Graphite has built a strong reputation for delivering superior products and exceptional customer service. The company's commitment to innovation and continuous improvement has allowed it to stay ahead of the competition and maintain its position as a market leader in the graphite industry.The new product, which has been developed after years of research and development, is set to revolutionize the casting industry. It offers unparalleled performance and durability, making it the ideal choice for a wide range of casting applications.Casting Graphite's new product is specially designed to meet the demanding requirements of modern casting processes. It offers excellent thermal stability and resistance to high temperatures, making it suitable for use in the most challenging casting environments. In addition, the product's unique composition provides superior strength and rigidity, ensuring exceptional performance and reliability in the casting process.The launch of this new product marks an important milestone for Casting Graphite, as it expands its product portfolio and strengthens its position in the global market. With growing demand for high-quality graphite casting materials, the company is well-positioned to seize new opportunities and capitalize on emerging trends in the industry."This new product represents a significant advancement in graphite casting technology," said [CEO's name], CEO of Casting Graphite. "We are excited to bring this innovation to our customers and provide them with a superior solution that meets their evolving needs. With our extensive experience and technical expertise, we are confident that this product will set new standards for performance and reliability in the casting industry."As Casting Graphite continues to grow and evolve, it remains committed to its core values of quality, innovation, and customer satisfaction. The company's dedication to excellence and its forward-thinking approach have earned it a solid reputation as a preferred partner for businesses seeking advanced graphite solutions.In the coming months, Casting Graphite plans to introduce its new product to customers worldwide, leveraging its global distribution network and strong industry partnerships to reach new markets and expand its customer base. With a focus on continuous improvement and a dedication to meeting the needs of its customers, the company is poised for further success and growth in the years to come.To learn more about Casting Graphite and its innovative graphite casting solutions, visit [company website] for additional information and product details.

Durable Metal Melting Crucible for High-temperature Applications

Metal Melting Crucible: The Essential Component in Metal Casting ProcessesMetal melting crucible is an indispensable tool in the metal casting industry, as it plays a crucial role in melting and pouring various types of metals into molds to create a wide range of products. From jewelry and decorative items to industrial components and automotive parts, metal casting is a versatile and essential process in manufacturing.The metal melting crucible is a container that withstands high temperatures and is used to melt various types of metals, such as gold, silver, bronze, and aluminum, among others. It is designed to withstand the intense heat necessary to melt these metals and is often made of materials such as graphite, ceramic, or refractory metals. The crucible is placed inside a furnace or melting kiln, where the metal is heated until it reaches its melting point, at which point it can be poured into molds to take on the desired shape.One company that has made significant contributions to the metal casting industry is {}. With over 20 years of experience in manufacturing and supplying high-quality metal melting crucibles and other related products, {} has become a recognized leader in the industry. The company's commitment to innovation, quality, and customer satisfaction has earned them a strong reputation among metal casting professionals worldwide.{} offers a wide range of metal melting crucibles to suit the diverse needs of its customers. Whether they are working with precious metals for jewelry making or industrial metals for large-scale manufacturing, {} provides crucibles that are durable, heat-resistant, and capable of withstanding the rigors of the metal casting process. The company's crucibles are designed to ensure efficient and consistent metal melting, resulting in high-quality castings with minimal waste.In addition to metal melting crucibles, {} also offers a comprehensive range of casting tools and equipment, including melting furnaces, casting molds, and crucible tongs, among others. This allows customers to source all their metal casting needs from a single, reliable supplier, streamlining the procurement process and ensuring seamless compatibility between different components of the casting system.One of {}'s key strengths is its commitment to continuous improvement and innovation. The company invests heavily in research and development to enhance the performance and durability of its products, as well as to develop new solutions to address the evolving needs of the metal casting industry. By staying at the forefront of technological advancements and industry trends, {} remains a trusted partner for metal casting professionals seeking reliable and efficient equipment.Furthermore, {} places a strong emphasis on customer service, aiming to provide personalized support and tailored solutions to its clients. The company's team of experienced professionals is dedicated to understanding the specific requirements of each customer and offering expert advice on choosing the most suitable products for their applications. This consultative approach has contributed to {}'s reputation as a trusted partner in the metal casting industry.As the demand for metal castings continues to grow across various sectors, the role of metal melting crucibles in the manufacturing process becomes increasingly pivotal. With {}'s steadfast commitment to quality, innovation, and customer satisfaction, the company is well-positioned to remain a leading supplier of metal melting crucibles and related products for the foreseeable future.In conclusion, metal melting crucibles are an essential component in metal casting processes, enabling manufacturers to transform raw metals into a wide variety of products. With its extensive experience, innovative approach, and commitment to customer satisfaction, {} has established itself as a reliable and respected supplier of metal melting crucibles and related equipment, providing valuable support to the metal casting industry.

Surging Sales of Graphite Electrodes: Impact on the Market Analyzed

Graphite Electrode Industry Sees Robust Growth in Sales The global graphite electrode industry has witnessed an impressive surge in sales over the past year, driven by increasing demand from various end-use sectors such as steel, aluminum, and silicon metals. The notable growth in sales can be attributed to several factors, including the rising consumption of steel in the construction and automotive sectors, as well as the rapid development of the electric vehicle market.Graphite electrodes are primarily used in electric arc furnaces (EAFs) for steel production, providing the necessary electrical conductivity to melt scrap metal and produce high-quality steel. As the construction and automotive industries continue to expand, the demand for steel is expected to surge, subsequently driving the growth of the graphite electrode market.Furthermore, the growing environmentally-conscious mindset of consumers has led to an increased adoption of electric vehicles (EVs) worldwide. Electric vehicles rely heavily on lightweight materials such as aluminum and silicon metals, both of which require graphite electrodes for their production. This has significantly boosted the demand for graphite electrodes in the aluminum and silicon metals industries, further contributing to the overall growth in sales.One of the key players in the graphite electrode industry, a renowned company with extensive experience, has experienced tremendous success in recent years, as reflected in their robust sales growth. This company, which specializes in the manufacturing and distribution of high-quality graphite electrodes, has witnessed a significant rise in sales thanks to its strong market presence and reputation for delivering superior products.A critical factor that sets this company apart from its competitors is its commitment to research and development. By continuously investing in innovation and advanced technologies, the company has been able to develop cutting-edge graphite electrode solutions that cater to the evolving needs and requirements of the steel, aluminum, and silicon metals industries. This has further solidified their position as a trusted supplier among their clientele.Moreover, the company's extensive distribution network has played a crucial role in its sales growth. With a wide-reaching distribution presence across key regions and markets, the company has been able to efficiently meet the increasing demand for graphite electrodes. This widespread availability of their products has not only bolstered their sales but has also solidified their reputation as a reliable and accessible supplier.Additionally, the company places great emphasis on customer satisfaction by providing exceptional after-sales services. They understand the importance of building long-term relationships with their customers, and thus, strive to offer comprehensive technical support and prompt assistance whenever needed. This dedication to customer service has proven to be a critical factor in their success, leading to increased customer loyalty and repeat business.Looking ahead, the global graphite electrode industry is expected to continue experiencing remarkable growth. The increased consumption of steel and the ongoing transition towards electric vehicles are projected to drive the demand for graphite electrodes even further. As the industry evolves, companies like the one mentioned above will play a vital role in providing innovative solutions and meeting the escalating demand.In conclusion, the graphite electrode industry is witnessing an impressive surge in sales, primarily driven by the robust demand from the steel, aluminum, and silicon metals sectors. The company discussed above, with its focus on research and development, extensive distribution network, and commitment to customer satisfaction, has emerged as a leading player in the industry. As the market continues to grow, it is anticipated that the sales of graphite electrodes will continue to rise, providing ample opportunities for further growth and expansion in the sector.