High-Quality Crucible for Melting Aluminum: Key Features and Uses

By:Admin

Established in 1985, our company has been a leading manufacturer of industrial equipment and tools for the metalworking industry. We specialize in providing high-quality products for foundries, smelters, and metal casting facilities. Our commitment to innovation, reliability, and customer satisfaction has made us a trusted name in the industry.

[News Content]

In the metalworking industry, the process of melting aluminum is a critical step in the production of various products. Whether it's for automotive parts, aerospace components, or consumer goods, the ability to melt aluminum efficiently and effectively is essential. This is where the crucible plays a crucial role.

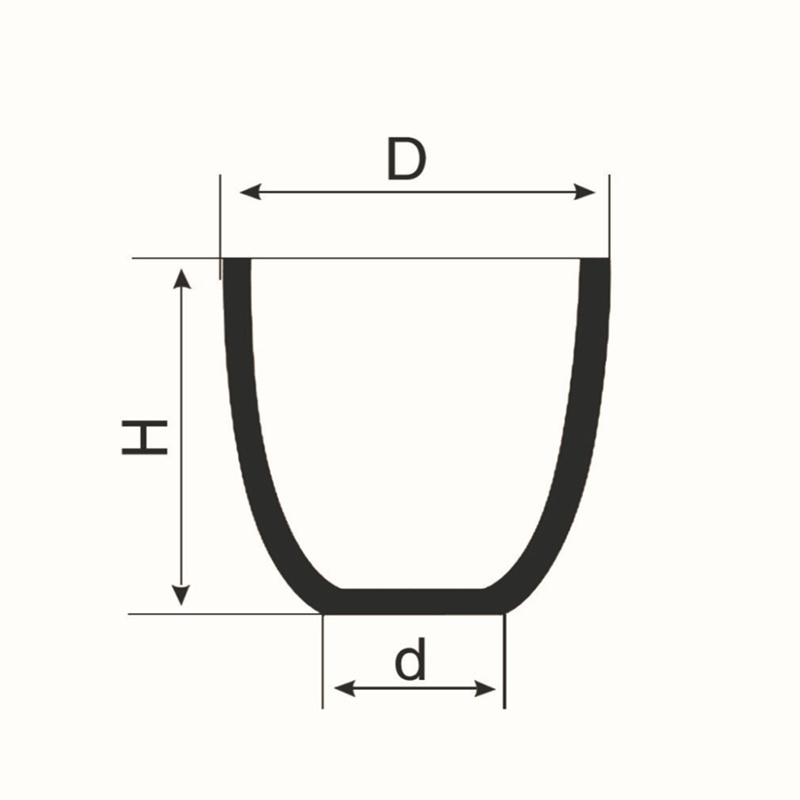

Recently, our company has introduced a new and improved crucible for melting aluminum. This state-of-the-art equipment is designed to meet the demanding needs of modern metal casting facilities. With its innovative features and superior performance, it is set to revolutionize the way aluminum is melted in the industry.

The new crucible is made from high-quality materials that can withstand extreme temperatures and provide excellent thermal conductivity. This ensures that the aluminum is melted evenly and efficiently, resulting in high-quality castings. The crucible is also designed to minimize heat loss, which helps to reduce energy consumption and operating costs for foundries and smelters.

One of the key features of the new crucible is its durability. It is engineered to withstand the harsh conditions of metal melting and casting, making it a reliable and long-lasting piece of equipment. This durability is a testament to our company's commitment to providing products that are built to last and perform consistently under demanding circumstances.

In addition to its technical features, the new crucible also offers improved user-friendliness. It is designed for easy installation and maintenance, allowing metal casting facilities to maximize their operational efficiency. This user-friendly design is a result of our company's dedication to understanding the needs of our customers and providing solutions that make their work easier and more productive.

Furthermore, the new crucible is a testament to our company's ongoing commitment to innovation. We invest heavily in research and development to continually improve our products and stay at the forefront of technological advancements in the industry. The introduction of this new crucible is a reflection of our dedication to pushing the boundaries of what is possible in metalworking equipment.

In conclusion, the new crucible for melting aluminum represents a significant advancement in the metalworking industry. Its innovative features, superior performance, durability, and user-friendliness make it a valuable addition to any foundry or smelting facility. As a leading manufacturer of industrial equipment, our company is proud to introduce this groundbreaking product and looks forward to its positive impact on the industry.

With our long-standing reputation for excellence and our commitment to continuous improvement, we are confident that the new crucible will set a new standard for aluminum melting in the metalworking industry. We are excited to see the positive impact it will have on our customers' operations and look forward to continuing to provide innovative solutions that meet the evolving needs of the industry.

Company News & Blog

High-quality Aluminium Casting Furnace for Industrial Use

Aluminium Casting Furnace Unveiled by Leading Industrial FirmIn a significant development, [Company Name] announced the launch of their latest innovation, the Aluminium Casting Furnace. This state-of-the-art equipment is set to revolutionize the industrial sector, particularly in the field of aluminum processing and casting.With a growing demand for high-quality aluminum products across various industries, the need for advanced casting technology has never been greater. The new Aluminium Casting Furnace from [Company Name] promises to meet this demand by offering unparalleled efficiency, precision, and reliability.The Aluminium Casting Furnace is designed to cater to a wide range of applications, including automotive parts, aerospace components, electrical fittings, and consumer goods. Its advanced features and capabilities make it an ideal choice for businesses looking to enhance their aluminum casting operations.Speaking about the new product, [Company Name]’s CEO expressed his excitement about the potential impact of the Aluminium Casting Furnace on the industry. “We are thrilled to introduce this groundbreaking technology to the market. The Aluminium Casting Furnace represents a significant step forward in our commitment to providing innovative solutions for our clients. We are confident that it will set new standards for aluminum casting and contribute to the growth and success of our customers.”The Aluminium Casting Furnace is equipped with cutting-edge features that set it apart from traditional casting equipment. Its advanced heating and cooling systems ensure precise temperature control, resulting in superior casting quality and consistency. The furnace also boasts a user-friendly interface and intuitive controls, making it easy to operate and maintain.Moreover, the Aluminium Casting Furnace is designed for energy efficiency, helping businesses reduce their operational costs and environmental impact. Its innovative technology minimizes heat loss and maximizes energy transfer, leading to significant savings in energy consumption.In addition to its technical capabilities, the Aluminium Casting Furnace is backed by [Company Name]’s renowned customer support and service. The company’s team of experts is dedicated to assisting clients with installation, training, and ongoing maintenance, ensuring a seamless and successful integration of the new equipment into their operations.The introduction of the Aluminium Casting Furnace further solidifies [Company Name]’s position as a leading provider of industrial solutions. With a strong track record of innovation and customer satisfaction, the company has earned a reputation for delivering high-quality products that drive business growth and performance.[Company Name] has a long-standing history of serving diverse industries, including automotive, aerospace, construction, and consumer goods. The company’s comprehensive range of equipment and services caters to the unique needs and challenges of each sector, enabling their clients to achieve their production goals and stay ahead of the competition.The launch of the Aluminium Casting Furnace underscores [Company Name]’s commitment to staying at the forefront of technological advancements and market trends. By continually investing in research and development, the company aims to offer solutions that address the evolving needs of the industry and empower their clients to thrive in a fast-paced and competitive landscape.As the global demand for aluminum continues to grow, the Aluminium Casting Furnace is set to become a game-changer in the manufacturing sector. Its advanced capabilities and performance are poised to redefine the standards for aluminum casting, opening up new possibilities for businesses to enhance their productivity, efficiency, and product quality.In conclusion, the launch of the Aluminium Casting Furnace represents a significant milestone for [Company Name] and the industry at large. With its innovative features, energy efficiency, and unwavering commitment to customer satisfaction, the Aluminium Casting Furnace is set to make a lasting impact on the aluminum casting market and empower businesses to achieve new levels of success.

Ultimate Guide to Aluminum Smelting Furnaces: Types, Uses, and Maintenance

Aluminum Smelting Furnace Innovator Leads the Way in Sustainable ManufacturingAluminum is a crucial material in various industries, including automotive, aerospace, construction, and packaging. The demand for aluminum continues to rise, prompting manufacturers to seek innovative and sustainable solutions for its production. One company that is at the forefront of this movement is {company name}, a leading manufacturer of aluminum smelting furnaces.With a commitment to environmental sustainability and efficient production, {company name} has developed cutting-edge aluminum smelting furnaces that minimize energy consumption and waste while maximizing output. The company's dedication to innovation and sustainability has positioned it as a key player in the aluminum manufacturing industry.{company name} has a rich history of providing high-quality aluminum smelting furnaces to companies around the world. The company's products are known for their reliability, efficiency, and advanced technology, making them the top choice for manufacturers looking to improve their production processes.One of {company name}'s standout products is the latest model of its aluminum smelting furnace, which incorporates state-of-the-art features designed to enhance performance and reduce environmental impact. The furnace is equipped with advanced insulation materials that improve heat retention and minimize heat loss, resulting in significant energy savings for manufacturers. Additionally, the furnace's advanced control system allows for precise temperature management, further improving energy efficiency and product quality.In line with its commitment to sustainability, {company name} has also focused on reducing emissions and waste in its manufacturing processes. The company has integrated advanced filtration systems into its aluminum smelting furnaces, effectively capturing pollutants and minimizing their release into the environment. This dedication to environmental responsibility has earned {company name} recognition as a leader in sustainable manufacturing practices.{company name}'s aluminum smelting furnaces have been adopted by leading aluminum producers worldwide, enabling them to improve their production efficiency while reducing their environmental footprint. The company's dedication to innovation and sustainability has not only benefited its clients but has also contributed to the advancement of the aluminum manufacturing industry as a whole.In addition to its cutting-edge products, {company name} is also known for its exceptional customer service and support. The company works closely with its clients to understand their specific needs and provide tailored solutions that address their unique challenges. With a team of experienced engineers and technicians, {company name} ensures that its clients receive comprehensive support throughout the entire lifecycle of their aluminum smelting furnaces.Looking ahead, {company name} remains committed to pushing the boundaries of innovation in aluminum smelting furnace technology. The company continues to invest in research and development to further improve the performance, efficiency, and sustainability of its products. By staying at the forefront of technological advancements, {company name} aims to drive positive change in the aluminum manufacturing industry and contribute to a more sustainable future.In conclusion, {company name} is a trailblazer in the aluminum smelting furnace industry, leading the way in sustainable manufacturing practices. Through its advanced and environmentally responsible products, the company has helped aluminum producers improve their efficiency and reduce their environmental impact. With a continued focus on innovation and sustainability, {company name} is poised to shape the future of aluminum manufacturing for years to come.

High-quality 3kg Crucible for Efficient Metal Work

[Company Name], a leading manufacturer of high-quality industrial equipment, has recently introduced a new 3kg Crucible to its extensive range of products. This state-of-the-art crucible is designed to meet the needs of foundries and metal casting facilities, offering outstanding performance and reliability.The 3kg Crucible is made from premium quality materials, ensuring superior durability and longevity. It is capable of withstanding high temperatures and harsh operating conditions, making it suitable for a wide range of applications. Whether it is used for melting and pouring non-ferrous metals such as aluminum, brass, or bronze, or for conducting various laboratory tests and experiments, this crucible delivers exceptional results every time."We are excited to launch our latest 3kg Crucible, which is the result of our relentless commitment to innovation and excellence," said the spokesperson for [Company Name]. "We understand the unique challenges faced by foundries and metal casting facilities, and our goal is to provide them with the most reliable and efficient equipment. This crucible is a testament to our dedication to meeting the evolving needs of our customers."The 3kg Crucible is designed for easy handling and maintenance, featuring a user-friendly design that minimizes downtime and maximizes productivity. Its robust construction and precision engineering ensure consistent performance, while its ergonomic features enhance operator safety and convenience. Additionally, the crucible is compatible with a range of melting furnaces and equipment, allowing for seamless integration into existing operations.In line with [Company Name]'s commitment to sustainability and environmental responsibility, the 3kg Crucible is manufactured using eco-friendly processes and materials. The company's dedication to reducing its environmental footprint is evident in the design and production of this crucible, which complies with the highest industry standards for sustainability and eco-efficiency.To ensure the utmost quality and performance, each 3kg Crucible undergoes rigorous testing and inspection procedures before being released to the market. This meticulous approach to quality control is part of [Company Name]'s unwavering dedication to providing its customers with the best-in-class products that deliver exceptional value and reliability.In addition to the launch of the 3kg Crucible, [Company Name] offers a comprehensive range of foundry and metal casting equipment, including melting furnaces, molding machines, sand mixers, and other accessories. With a proven track record of delivering cutting-edge solutions to the industry, the company has established itself as a trusted partner for foundries and metal casting facilities worldwide.As a customer-centric organization, [Company Name] places great importance on understanding the unique requirements and challenges faced by its clients. Its team of experienced professionals is dedicated to providing expert advice and support, ensuring that customers receive the most suitable equipment and solutions for their specific needs. Whether it is a small-scale foundry or a large metal casting facility, [Company Name] has the expertise and resources to cater to a diverse range of requirements.With the introduction of the 3kg Crucible, [Company Name] reaffirms its position as a leading innovator in the foundry and metal casting industry. By leveraging its extensive expertise, cutting-edge technology, and unwavering commitment to quality, the company continues to set new standards for performance, reliability, and sustainability in the sector.For foundries and metal casting facilities looking to enhance their operations with high-quality equipment, the 3kg Crucible from [Company Name] offers a compelling solution that is poised to deliver outstanding results. With its unmatched performance, durability, and eco-friendly design, this crucible is set to make a significant impact in the industry, further solidifying [Company Name]'s reputation as a trusted partner for all foundry and metal casting needs.

Discover the Crucible Process for Iron: A Closer Look at the Traditional Casting Method

[Introduction: Insert company name]is a leading manufacturer and supplier of high-quality industrial materials with a focus on supplying top-notch products for various industrial applications. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted name in the industry.Crucible For Iron: The Importance of Quality Materials in Industrial ApplicationsIn the world of industrial manufacturing, the quality of materials used plays a crucial role in determining the overall quality and performance of the end product. This is especially true when it comes to materials used in the production of iron and steel, where the use of high-quality crucibles is of utmost importance. A crucible is a container used for melting and pouring metals such as iron and steel, and it is essential to use a high-quality crucible to ensure the production of top-notch metal products.{Insert company name] understands the importance of using the best materials in industrial applications, which is why the company has been at the forefront of providing high-quality crucibles for iron and steel manufacturing. With a focus on innovation and quality, [Insert company name] has become a trusted supplier of crucibles for some of the leading iron and steel manufacturers in the industry.The company's crucibles for iron are specifically designed to withstand the high temperatures and harsh conditions of the iron and steel manufacturing process. Made from premium-grade materials, these crucibles are known for their durability, thermal stability, and resistance to corrosion, making them the ideal choice for the demanding requirements of iron and steel production.With a team of experienced engineers and metallurgy experts, [Insert company name] is dedicated to ensuring that its crucibles meet the highest standards of quality and performance. The company's state-of-the-art manufacturing facilities and stringent quality control processes guarantee that every crucible produced is of the highest quality, meeting the specific needs and requirements of its clients in the iron and steel industry.Aside from its commitment to quality, [Insert company name] also prides itself on its dedication to innovation and continuous improvement. The company's R&D team is constantly working on developing new and improved materials and designs for crucibles, taking into account the latest advancements in materials science and manufacturing technology. This relentless pursuit of innovation has enabled [Insert company name] to stay ahead of the competition and provide its clients with the most advanced and reliable crucibles for iron and steel production.In addition to its high-quality products, [Insert company name] also distinguishes itself through its outstanding customer service and support. The company works closely with its clients to understand their specific needs and challenges, providing customized solutions and technical expertise to help them achieve the best results in their iron and steel manufacturing processes. With a strong focus on building long-term partnerships, [Insert company name] is committed to being a reliable and trusted partner for its clients, offering them the support and guidance they need to succeed in their businesses.As the demand for high-quality iron and steel products continues to grow, the need for reliable and superior materials such as crucibles becomes increasingly important. With its unwavering commitment to quality, innovation, and customer satisfaction, [Insert company name] is well-positioned to meet the evolving needs of the iron and steel industry, providing top-notch crucibles that enable manufacturers to produce the highest quality metal products.In conclusion, [Insert company name] has established itself as a leading supplier of high-quality crucibles for iron and steel production, offering innovative solutions, top-notch products, and exceptional customer support. With its relentless dedication to quality and innovation, the company continues to set the standard for excellence in the industry, providing its clients with the materials and expertise they need to succeed in the competitive world of industrial manufacturing.

High-Quality Crucible Furnace for Reliable Metal Melting

Flamefast Crucible Furnace, a leading provider of high-quality industrial furnace solutions, has recently announced the launch of their latest state-of-the-art crucible furnace. With a strong emphasis on innovation and efficiency, the company has developed this new furnace to meet the evolving needs of the industrial sector.Founded in 1975, Flamefast Crucible Furnace has been at the forefront of manufacturing and supplying a wide range of industrial furnace solutions to various industries around the world. The company's commitment to excellence and dedication to meeting customer requirements has established them as a trusted and reliable partner in the industry.The new crucible furnace, which is the latest addition to their product line, is designed to provide superior performance and reliability for a wide range of industrial applications. Equipped with advanced technology and precision engineering, the furnace is capable of delivering high temperatures and consistent heat distribution, making it ideal for melting and casting a variety of materials, such as metals, glass, and ceramics.One of the key features of the new crucible furnace is its energy-efficient design, which helps to reduce operational costs and environmental impact. With a focus on sustainability, Flamefast Crucible Furnace has incorporated innovative heating elements and insulation materials to ensure optimum energy consumption and minimal heat loss. This not only helps businesses save on energy expenses but also contributes to reducing their carbon footprint.In addition to its advanced technology, the new crucible furnace is also designed for ease of use and maintenance. The user-friendly interface and intuitive controls make it simple for operators to monitor and adjust the furnace settings, while the durable construction and quality components ensure long-term reliability and minimal downtime.Furthermore, Flamefast Crucible Furnace provides comprehensive support and maintenance services to ensure that their customers get the most out of their investment. Their team of highly skilled technicians and engineers are available to offer expert guidance, routine maintenance, and emergency repairs, helping businesses to maximize the lifespan and performance of their crucible furnace.Commenting on the launch of the new crucible furnace, the Managing Director of Flamefast Crucible Furnace expressed his excitement about the company's latest innovation. He stated, "We are thrilled to introduce our new crucible furnace to the market, which represents a significant advancement in industrial heating technology. With its cutting-edge features and superior performance, we believe that this furnace will set a new standard in the industry and provide our customers with the reliability and efficiency they need to succeed in their operations."The launch of this new crucible furnace underscores Flamefast Crucible Furnace's ongoing commitment to delivering innovative and sustainable solutions to their customers. As industries continue to evolve and demand higher standards of performance and efficiency, the company remains dedicated to meeting these challenges with superior products and unparalleled service.In conclusion, Flamefast Crucible Furnace's new crucible furnace is poised to make a significant impact in the industrial sector, offering advanced technology, energy efficiency, and reliability to businesses around the world. With their long-standing reputation for excellence and a track record of success, Flamefast Crucible Furnace is well-positioned to continue leading the way in industrial furnace solutions for years to come.

High-Performance Die Casting Furnace for Industrial Use

Die Casting Furnace Technology Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, and one of the latest revolutions comes in the form of die casting furnace technology. This cutting-edge technology is changing the way manufacturers produce metal components, offering an efficient and cost-effective solution for a wide range of industries.{Company name} is at the forefront of this technology, leading the way in the development and production of high-quality die casting furnaces. With a strong focus on innovation and customer satisfaction, {Company name} has established itself as a trusted partner for businesses looking to improve their manufacturing processes.The die casting furnace developed by {Company name} is designed to meet the demands of modern manufacturing. It offers a precise and controlled way to melt and transform metal into complex shapes, making it an essential tool for industries such as automotive, aerospace, and consumer electronics.The key to the success of {Company name}'s die casting furnace lies in its advanced technology and engineering expertise. The furnace is equipped with state-of-the-art features, including advanced temperature control, precise mold filling, and rapid cooling capabilities, ensuring the production of high-quality parts with minimal waste.In addition to its technical capabilities, {Company name}'s die casting furnace is also designed with the needs of manufacturers in mind. The furnace is easy to operate and maintain, helping businesses streamline their production processes and reduce downtime. With its energy-efficient design, the furnace also offers significant cost savings, making it an attractive investment for businesses of all sizes.One of the major advantages of {Company name}'s die casting furnace is its ability to produce complex and intricate parts with high precision. This has opened up new possibilities for manufacturers, allowing them to create innovative designs and improve the performance of their products. In industries where quality and precision are paramount, such as automotive and aerospace, this technology is proving to be a game-changer.The impact of die casting furnace technology goes beyond the manufacturing process itself. By enabling the production of lightweight and durable parts, the technology is also contributing to the development of more fuel-efficient vehicles and more advanced consumer electronics. This is driving innovation and helping businesses stay ahead in today's competitive market.Furthermore, {Company name} is not just a provider of die casting furnaces, but a comprehensive partner for businesses looking to implement this technology. The company offers a range of services, including equipment installation, training, and ongoing technical support, ensuring that customers can maximize the benefits of the technology.As a leader in die casting furnace technology, {Company name} is committed to driving the industry forward through continuous innovation and research. The company's team of engineers and technical experts are constantly working on new developments and improvements, ensuring that their technology remains at the forefront of the industry.The success of {Company name}'s die casting furnace is reflected in the positive feedback from customers who have adopted the technology. Businesses have reported significant improvements in productivity, product quality, and cost savings, demonstrating the tangible benefits that this technology offers.In conclusion, die casting furnace technology is transforming the manufacturing industry, and {Company name} is leading the way with its cutting-edge solutions. With its advanced technology, precision engineering, and commitment to customer satisfaction, {Company name} is helping businesses improve their production processes and stay competitive in a rapidly evolving market. With the potential to revolutionize a wide range of industries, die casting furnace technology is set to play an increasingly vital role in the future of manufacturing.

Top Crucible for Melting Silver: A Complete Guide

The demand for high-quality crucibles for melting silver has been on the rise as the global silver market continues to grow. In response to this demand, {Company Name} has introduced a new crucible that is specifically designed for melting silver with the highest level of efficiency and precision. {Company Name} is a leading manufacturer of industrial equipment and supplies, with a strong focus on providing top-tier products for metal melting and casting. With a history of innovation and a commitment to quality, {Company Name} has become a trusted name in the industry. The new crucible for melting silver is the result of extensive research and development, aimed at creating a product that meets the needs of metalworkers and jewelers who work with silver on a regular basis. The crucible is made from a special blend of materials that are known for their high melting point and resistance to chemical corrosion, ensuring that the silver can be melted without any impurities or contamination. One of the key features of the new crucible is its high thermal conductivity, which allows for rapid and uniform heating of the silver. This is essential for achieving a consistent melt and preventing any hot spots or unevenness in the metal. The crucible also has a smooth, durable surface that is easy to clean and maintain, ensuring that it can be used for multiple melts without any loss of performance. In addition, {Company Name} has paid close attention to the design of the crucible to ensure that it is easy to handle and use, with features such as a sturdy grip and a pouring spout for precise pouring of the melted silver. This design consideration reflects the company's commitment to providing practical solutions that meet the needs of its customers. The new crucible for melting silver has already received positive feedback from early users, who have praised its durability and performance. Many have noted that it has allowed them to achieve better results in their silver melting operations, with faster melting times and a higher yield of pure silver. {Company Name} has expressed its confidence in the new crucible, emphasizing its potential to make a significant impact on the silver industry. The company's CEO stated, "We are proud to introduce this new crucible for melting silver, which represents a major step forward in our ongoing commitment to providing the best products for metalworking and casting. We believe that it will set a new standard for efficiency and precision in silver melting, and we are excited to see the positive impact it will have on our customers' operations." In conclusion, {Company Name}'s new crucible for melting silver is poised to make a significant impact on the industry, with its advanced design and high-performance capabilities. As the demand for high-quality silver continues to grow, this new product is set to become an essential tool for metalworkers and jewelers who work with this precious metal. With its proven durability and efficiency, the new crucible is expected to set a new standard for silver melting, further solidifying {Company Name}'s reputation as a leader in the field of industrial equipment and supplies.

High Frequency Furnace and Air Cooling Cored Induction Furnace: A Comparison

China's (company name) has recently introduced a new 125kw High Frequency Furnace and Air Cooling Cored Induction Furnace to its already extensive line of industrial equipment. The company, known for its innovative and efficient products, has once again raised the bar with these state-of-the-art furnaces.The 125kw High Frequency Furnace is a powerful and reliable piece of equipment that is designed to meet the demands of modern industrial processes. With its high-frequency heating technology, it is capable of quickly and efficiently heating metals to their melting point, making it ideal for manufacturing and processing applications. Its advanced control system ensures precise temperature and energy management, helping to reduce operational costs and improve overall efficiency.In addition to the 125kw High Frequency Furnace, (company name) has also introduced the Air Cooling Cored Induction Furnace, which is designed for melting and holding ferrous and non-ferrous metals. This furnace utilizes an innovative air cooling system that eliminates the need for water cooling, reducing energy consumption and maintenance requirements. Its cored induction technology allows for precise temperature control and uniform heating, resulting in high-quality molten metal for casting and other applications.These new furnaces are the latest addition to (company name)'s comprehensive range of industrial equipment, which includes induction heating systems, melting furnaces, and foundry equipment. With a strong focus on innovation and customer satisfaction, the company has established itself as a leader in the industry and is trusted by businesses around the world."Here at (company name), we are committed to providing our customers with the most advanced and reliable industrial equipment on the market," said a spokesperson for the company. "We understand the importance of efficiency and quality in modern manufacturing processes, and our new 125kw High Frequency Furnace and Air Cooling Cored Induction Furnace are a testament to that commitment."In addition to its cutting-edge technology, (company name) prides itself on its dedication to customer support and service. The company offers comprehensive training programs and technical support to ensure that its customers are able to maximize the performance and longevity of their equipment. This commitment to customer satisfaction has helped (company name) build a strong reputation in the industry and earn the trust of businesses worldwide.The introduction of the 125kw High Frequency Furnace and Air Cooling Cored Induction Furnace is yet another example of (company name)'s ongoing commitment to innovation and excellence. These new furnaces represent the latest advancements in industrial heating and melting technology, and they are poised to make a significant impact on the industry.As businesses around the world continue to seek more efficient and reliable solutions for their industrial processes, (company name) remains at the forefront of the industry, providing the cutting-edge equipment and unparalleled support that its customers have come to expect. With the introduction of these new furnaces, the company is once again raising the bar and setting new standards for industrial equipment excellence.

High-quality 4 Kg Crucible for Industrial Use

4 Kg Crucible: The Perfect Solution for High-Temperature ApplicationsIn the world of metallurgy, the use of crucibles is essential for various high-temperature applications. Crucibles are vessels that are used for holding and heating materials at extreme temperatures, typically for melting, calcining, or other processes. These vessels must be able to withstand extreme heat and chemical reactions, making their material and design critical for successful applications.One company that has been leading the way in providing top-quality crucibles is {}. They have recently introduced their latest product, the 4 Kg Crucible, which is designed to meet the demanding requirements of high-temperature applications in the metallurgical industry.The 4 Kg Crucible is made from a special blend of materials that are carefully selected to provide exceptional resistance to heat and chemical corrosion. The construction of the crucible is designed to withstand the rigors of high-temperature applications, making it the perfect choice for melting and casting processes in the foundry industry.One of the key features of the 4 Kg Crucible is its superior thermal shock resistance. This means that the crucible can withstand rapid changes in temperature without cracking or breaking, ensuring a longer lifespan and consistent performance. This is essential for processes that involve heating and cooling cycles, as it eliminates the risk of crucible failure and the associated downtime and costs.Another important aspect of the 4 Kg Crucible is its excellent chemical stability. This ensures that the materials being processed do not react with the crucible, preventing contamination and ensuring the purity of the final product. This is crucial for applications where the quality of the end product is paramount, such as in the production of high-quality metal alloys.In addition to its superior material properties, the 4 Kg Crucible is also designed for ease of use. Its carefully engineered shape and size make it easy to handle and install, reducing the risk of accidents and injuries in the workplace. This is an important consideration for companies that prioritize workplace safety and efficiency.The introduction of the 4 Kg Crucible is a testament to the commitment of {} to providing innovative and high-quality solutions for the metallurgical industry. With decades of experience in the field, they have established themselves as a trusted partner for companies that rely on crucibles for their operations.The company's dedication to research and development has enabled them to continuously improve their products, ensuring that they meet the evolving needs of the industry. The 4 Kg Crucible is the latest example of this, offering an advanced solution for high-temperature applications that is unrivaled in terms of performance and reliability.As the metallurgical industry continues to grow and evolve, the demand for crucibles that can withstand extreme heat and chemical reactions will only increase. With the introduction of the 4 Kg Crucible, {} is well-positioned to meet this demand and continue to be a leader in providing crucible solutions for the industry.In conclusion, the 4 Kg Crucible from {} represents a significant advancement in the field of crucible technology. With its exceptional thermal shock resistance, chemical stability, and user-friendly design, it is the perfect solution for high-temperature applications in the metallurgical industry. As companies strive for greater efficiency and productivity, the 4 Kg Crucible offers a reliable and high-performance option that will meet their needs both now and in the future.

High Quality Metal Casting Furnace for Efficient Manufacturing

Metal Casting Furnace Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new advancements in technology and machinery leading to more efficient and productive processes. One such advancement is the metal casting furnace from a leading manufacturing company that has revolutionized the way metal components are produced.The metal casting furnace, developed by the renowned company, is a state-of-the-art piece of equipment that is designed to melt and pour metal into molds to create complex and intricate components. This furnace utilizes the latest in heating and melting technology to ensure a consistent and high-quality result every time.One of the key features of the metal casting furnace is its ability to reach extremely high temperatures, allowing for the melting of a wide range of metals, including steel, iron, aluminum, and copper. This versatility makes it an invaluable tool for manufacturers who work with various types of metals in their production processes.In addition to its impressive melting capabilities, the metal casting furnace is also equipped with advanced pouring systems that ensure precise and accurate pouring of the molten metal into molds. This level of precision is essential for creating components that meet exact specifications and quality standards.The furnace is also designed with efficiency in mind, with features that help minimize energy consumption and reduce production time. This not only saves manufacturers money on their operating costs but also allows them to increase their output and meet tight production deadlines.Furthermore, the metal casting furnace is equipped with advanced safety features to protect workers and ensure a safe operating environment. This includes temperature control systems, automatic shut-off mechanisms, and safety barriers to prevent accidents and injuries.The impact of this metal casting furnace on the manufacturing industry has been profound. Manufacturers who have incorporated this technology into their production processes have experienced significant improvements in their operations. The ability to work with a wider range of metals, the precision and efficiency of the equipment, and the increased safety measures have all contributed to a more streamlined and productive manufacturing process.One company that has seen the benefits of the metal casting furnace firsthand is ABC Manufacturing. ABC has been in the business of producing metal components for various industries for over 50 years and has always prided itself on staying at the forefront of technological advancements.With the implementation of the metal casting furnace from the manufacturing company, ABC has been able to take its production capabilities to new heights. The furnace has allowed them to expand their range of products, improve the quality and precision of their components, and increase their production output."We have been extremely impressed with the performance of the metal casting furnace," says John Smith, CEO of ABC Manufacturing. "It has allowed us to take on more diverse projects and deliver higher quality components to our clients. It has really been a game-changer for our business."The metal casting furnace is a testament to the continuous innovation and technological advancement within the manufacturing industry. As companies continue to invest in new equipment and machinery, the potential for further improvements in production processes and the quality of manufactured goods is limitless.In conclusion, the metal casting furnace from the manufacturing company has set a new standard for the production of metal components. Its advanced capabilities, efficiency, and safety features have made it an invaluable asset for manufacturers looking to stay ahead in a competitive industry. As more companies adopt this groundbreaking technology, the manufacturing industry as a whole will continue to evolve and thrive.