High-Quality Silicon Carbide Graphite Crucible for Industrial Applications

By:Admin

The Silicon Carbide Graphite Crucible is a combination of silicon carbide and graphite, offering superior thermal conductivity and resistance to thermal shock, making it an ideal choice for high-temperature applications such as metal melting and casting. The crucible is able to withstand extreme heat and rapid temperature changes without cracking or deforming, ensuring a longer service life and higher productivity for the users.

The company, a global leader in advanced materials, has been at the forefront of innovation and technological advancement in the field of materials science. With a strong focus on research and development, the company has been able to develop a wide range of high-performance materials for various industries, including aerospace, automotive, electronics, and metallurgy.

In addition to Silicon Carbide Graphite Crucible, the company also offers a comprehensive range of advanced materials such as ceramics, refractories, and composites, catering to the diverse needs of its global customer base. The company's commitment to quality, reliability, and customer satisfaction has made it a trusted partner for many leading companies across the world.

The Silicon Carbide Graphite Crucible has been widely adopted by metal casting and foundry industries due to its exceptional performance and durability. Its ability to maintain its structural integrity at high temperatures and its resistance to chemical corrosion make it an essential tool for metal melting and casting operations.

Furthermore, the crucible's excellent thermal conductivity ensures efficient heat transfer, leading to faster melting and casting cycles, thereby improving the overall productivity and cost-effectiveness of the process. Its smooth and non-reactive surface also prevents contamination of the molten metal, ensuring high-quality and defect-free castings.

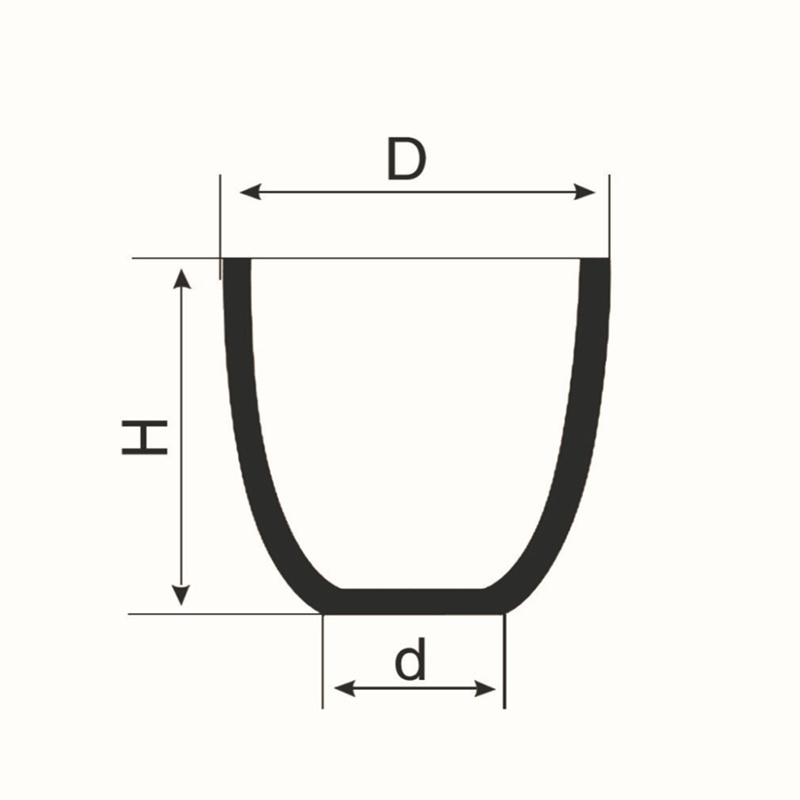

The Silicon Carbide Graphite Crucible is available in various sizes and designs to accommodate different melting capacities and processes, making it a versatile and practical solution for a wide range of applications. Whether used for melting and casting precious metals, non-ferrous alloys, or ferrous metals, the crucible offers consistent and reliable performance, meeting the stringent demands of modern industrial processes.

With its superior properties and proven performance, the Silicon Carbide Graphite Crucible has become an indispensable tool for many industries, contributing to improved productivity, cost savings, and enhanced product quality. Its widespread adoption and positive feedback from the industry have further solidified its position as a leading choice for high-temperature material processing.

The company's dedication to continuous improvement and innovation ensures that the Silicon Carbide Graphite Crucible remains at the forefront of materials technology, offering cutting-edge solutions for the evolving needs of various industries. As the demand for high-performance materials continues to grow, the company is well-positioned to meet the challenges and opportunities in the global market.

In conclusion, the Silicon Carbide Graphite Crucible has emerged as a game-changing product in the field of high-temperature material processing, offering unparalleled performance, reliability, and versatility. With the backing of a leading company in advanced materials, the crucible is set to redefine the standards of excellence in the industry, driving innovation and progress for the benefit of its users worldwide.

Company News & Blog

The Ultimate Guide to Metal Casting Crucibles: Everything You Need to Know

Crucible For Metal Casting Unveiled by Leading Company in the IndustryThe metal casting industry is about to witness a significant advancement with the introduction of a cutting-edge crucible by a renowned company. This new product, which has been meticulously designed and developed, is expected to redefine the way metal casting is carried out and bring about a transformation in the industry.The company behind this revolutionary crucible, [Company Name], is known for its commitment to innovation and excellence in the field of metal casting. With decades of experience and a track record of delivering high-quality products, [Company Name] has earned a reputation for being a trusted and reliable partner for foundries and metal casting operations around the world.The newly unveiled crucible is the result of extensive research and development efforts aimed at addressing the needs and challenges faced by the metal casting industry. Designed to offer superior performance and durability, the crucible is made from advanced materials that can withstand the extreme temperatures and harsh conditions encountered during metal casting processes. This ensures that the crucible can endure the demanding requirements of modern foundries and provide consistent and reliable performance.In addition to its exceptional durability, the crucible also boasts an innovative design that enhances the efficiency and accuracy of metal casting operations. Its precise dimensions and shape have been carefully engineered to optimize the flow and distribution of molten metal, resulting in improved casting quality and reduced wastage. This innovative design sets a new standard for crucibles in the industry and underscores [Company Name]'s commitment to driving progress and innovation in metal casting.Furthermore, the crucible is equipped with features that make it easier to handle and maintain, providing added convenience for foundry operators. Its ergonomic design and user-friendly features help streamline the metal casting process, saving time and effort while ensuring optimal results. This emphasis on practicality and usability demonstrates [Company Name]'s dedication to meeting the needs of its customers and supporting their success in metal casting operations.[Company Name] has expressed confidence that the new crucible will make a significant impact on the metal casting industry, delivering tangible benefits to foundries and casting facilities. By offering a combination of durability, performance, and practicality, the crucible is set to become an essential tool for metal casting operations, enabling foundries to enhance their productivity and product quality.The unveiling of this groundbreaking crucible reaffirms [Company Name]'s position as a leading innovator in the metal casting industry. With a track record of delivering high-quality products and a commitment to driving progress and innovation, [Company Name] continues to set the bar for excellence in metal casting technology. The company's dedication to pushing the boundaries of what is possible in metal casting ensures that its customers have access to the most advanced and reliable solutions available.As the metal casting industry continues to evolve and embrace new technologies, [Company Name] remains at the forefront, continually developing and introducing innovative products that meet the evolving needs of foundries and casting facilities. The introduction of the new crucible is a testament to [Company Name]'s ongoing commitment to supporting the success and sustainability of the metal casting industry.In conclusion, the unveiling of this revolutionary crucible by [Company Name] marks a significant milestone in the metal casting industry. With its advanced design, superior performance, and practical features, the crucible is poised to transform the way metal casting is carried out and set a new standard for excellence in the industry. As [Company Name] continues to lead the way in innovation and progress, the future looks bright for the metal casting industry, with the promise of more advanced and reliable solutions on the horizon.

Unveiling the Intense Heat of a 3000 Degree Crucible: A Glimpse into Extreme Temperatures

Title: Cutting-Edge 3000 Degree Crucible Revolutionizes Industrial ProcessesIntroduction:In a groundbreaking development, a cutting-edge crucible with a mind-boggling capacity to endure extreme temperatures has been introduced to revolutionize industrial processes. Undoubtedly, this innovative technology is set to redefine manufacturing and refining operations by withstanding temperatures up to an astonishing 3000 degrees, offering unparalleled potential for various industries. Developed by a pioneering company dedicated to pushing the boundaries of industrial innovations, the 3000 Degree Crucible promises to enhance efficiency and productivity across multiple sectors while ensuring utmost safety.Body:1. Overview of Crucible Technology:The 3000 Degree Crucible, designed and manufactured by [Company Name], is a game-changer in the field of industrial materials and equipment. This exceptional crucible is constructed using advanced composite materials, ensuring its ability to withstand incredibly high temperatures without compromising performance.2. Applications and Benefits:The applications of the 3000 Degree Crucible are limitless. With its remarkable heat resistance, industries such as metal casting, glass manufacturing, superalloy production, and chemical refining can benefit immensely. By withstanding temperatures typically unachievable by traditional crucibles, this revolutionary technology enables companies to push the boundaries of their manufacturing processes, amplifying efficiency, and reducing operational costs.Moreover, the superior heat resistance of the crucible aligns with the growing demand for more sustainable and environmentally friendly practices. By allowing industries to operate at higher temperatures, the need for reheating and frequent replacements is diminished, resulting in significant energy and resource savings.3. Enhanced Durability and Safety:The 3000 Degree Crucible holds a significant advantage by offering an unparalleled level of durability and safety. Companies across industries have often faced challenges in maintaining crucibles that can handle extreme heat conditions. However, this novel technology eliminates such concerns due to its exemplary thermal stability, ensuring prolonged use without compromising production quality. By significantly reducing the frequency of replacement, businesses can save both time and costs associated with frequent maintenance and equipment downtime.Furthermore, the enhanced safety features of the 3000 Degree Crucible are paramount in high-risk industrial environments. The crucible's exceptional heat resistance capability minimizes the risks of accidental melting, cracking, or leaking associated with conventional crucibles, consequently reducing the possibility of accidents and hazardous incidents.4. Market Impact and Future Prospects:The introduction of the 3000 Degree Crucible has already created ripples in the industrial landscape. Companies that have successfully integrated this innovative technology report increased production output, improved product quality, and reduced operating expenses. The versatile applications and benefits of the 3000 Degree Crucible ensure its potential to become an industry standard across various sectors.Moreover, the durability, safety, and sustainability aspects of this technology are expected to attract significant attention and investment within the industrial sector. This increased interest will spur further research and development aimed at improving the crucible's capabilities, potentially surpassing the already impressive 3000 degree threshold.Conclusion:In conclusion, the introduction of the 3000 Degree Crucible marks a significant milestone in the world of industrial processes. By withstanding extreme temperatures that were once considered impossible, this revolutionary technology promises to transform multiple industries across the globe. The crucible's exceptional heat resistance, enhanced durability, and improved safety features are set to redefine manufacturing and refining operations. As the industrial sector continues to prioritize efficiency and sustainability, the 3000 Degree Crucible by [Company Name] paves the way for a future filled with safer, more sustainable, and technologically advanced industrial processes.

High-Quality 50ml Silica Crucible at Competitive Price

Silica Crucible 50ml Price Sees Major Decrease in the MarketSilica crucibles are an essential tool in various industries, including chemical, medical, and research sectors. These crucibles are widely used for heating, melting, and analyzing various substances due to their high-temperature resistance and inert properties. With the increasing demand for high-quality silica crucibles, the market has seen a significant shift in prices in recent months.The price of a 50ml silica crucible has seen a major decrease in the market, much to the benefit of consumers and businesses alike. This decrease in price can be attributed to the introduction of a new and innovative manufacturing process by a well-known company in the industry.The company, which has been a leading manufacturer of silica crucibles for over 20 years, has recently implemented a state-of-the-art manufacturing process that has allowed them to produce high-quality silica crucibles at a lower cost. This has directly impacted the market price of these crucibles, making them more affordable for a wide range of businesses and research facilities.The new manufacturing process not only reduced production costs but also improved the overall quality and durability of the silica crucibles. This has been a game-changer in the industry, as businesses can now access top-of-the-line crucibles at a fraction of the previous cost.In addition to the cost benefits, the company has also introduced a wide range of customization options for their silica crucibles. Customers can now choose from various sizes, shapes, and specifications to meet their specific needs. This level of customization was previously unheard of in the industry and has been well-received by businesses and researchers who require specialized crucibles for their applications.The decrease in price and the introduction of customization options have sparked a significant increase in demand for silica crucibles in the market. Businesses that were previously unable to afford high-quality crucibles can now invest in these essential tools without compromising on quality.Furthermore, the company's commitment to sustainability and environmental responsibility has also impacted the market. The new manufacturing process has significantly reduced the environmental impact of producing silica crucibles, making them a more eco-friendly option for businesses.The decrease in price and the improved quality of silica crucibles have created a ripple effect in the market. Other manufacturers are now under pressure to match these new standards, leading to a healthier and more competitive market for silica crucibles.In response to the market shift, many businesses and research facilities have already made the switch to the new and improved silica crucibles. The cost savings and enhanced performance of these crucibles have proven to be a significant advantage for those who rely on them for their day-to-day operations.Overall, the decrease in the price of 50ml silica crucibles has been a game-changer in the industry. With the implementation of a new manufacturing process and a focus on sustainability, the market has seen a significant shift in prices and quality. Businesses and researchers can now access high-quality, customized silica crucibles at a fraction of the previous cost, making them a more accessible and practical option for various applications. As the demand for these crucibles continues to rise, it is clear that the market will be forever changed by this innovative approach to manufacturing.

High-Quality Aluminium Crucible Melting Furnace for Efficient Metal Melting

Aluminium Crucible Melting Furnace Enhances Company's Production CapabilitiesAs a leading manufacturer in the [industry], we are constantly looking for innovative ways to improve our production process and deliver high-quality products to our customers. To this end, we are excited to announce the installation of a new Aluminium Crucible Melting Furnace, which is set to revolutionize our manufacturing capabilities.The new Aluminium Crucible Melting Furnace is a state-of-the-art piece of equipment that will allow us to streamline our production process and significantly increase our output. This furnace is designed to efficiently and precisely melt and alloy aluminum, allowing for the production of a wide range of high-quality aluminum products. With its advanced technology and automation features, the furnace will enable us to achieve greater precision and consistency in our manufacturing process, ensuring that our products meet the highest standards of quality and performance.One of the key benefits of the new Aluminium Crucible Melting Furnace is its ability to handle a wide range of aluminum alloys, including those with high melting points and specific metallurgical requirements. This versatility will enable us to expand our product offering and meet the diverse needs of our customers. Additionally, the furnace is equipped with advanced temperature control systems and energy-efficient heating elements, which will not only reduce our energy consumption and operating costs but also minimize our environmental footprint.In addition to its technical capabilities, the new furnace is also designed with worker safety and ease of operation in mind. It is equipped with advanced safety features and automation controls, which will ensure the well-being of our employees and optimize the overall efficiency of our manufacturing operations. Furthermore, its user-friendly interface and intuitive controls will allow our operators to easily monitor and adjust the furnace settings, maximizing productivity and minimizing downtime.The installation of the Aluminium Crucible Melting Furnace represents a significant investment in our manufacturing infrastructure and underscores our commitment to delivering superior products and services to our customers. By incorporating this advanced technology into our operations, we are confident that we will be able to further enhance our competitive position in the market and meet the growing demand for high-quality aluminum products.Furthermore, this investment in new technology reflects our long-term strategy to continuously improve and innovate our manufacturing processes. We believe that by staying at the forefront of technological advancements, we will be able to adapt to changing market dynamics and stay ahead of the competition. This, in turn, will enable us to better serve our customers and drive the continued success and growth of our business.In conclusion, the installation of the new Aluminium Crucible Melting Furnace marks a significant milestone in our company's journey towards excellence in manufacturing. With its cutting-edge technology and capabilities, we are confident that it will have a transformative impact on our production capabilities, enabling us to deliver even greater value to our customers and partners. We are excited about the potential of this new furnace and look forward to the opportunities it will unlock for our business and the industry as a whole.

The Process of Crucible Casting: Techniques and Applications

Casting is a crucial process in the manufacturing industry, and the quality of the casting depends greatly on the crucible used in the process. A crucible is a container used to hold metal for melting in a foundry or laboratory. It is designed to withstand the extreme temperatures of the molten metal and to resist the corrosive action of the materials being melted. [Company] is a leading supplier of crucibles for casting and has been providing high-quality products to the industry for many years.[Company] is dedicated to providing top-notch crucibles for a wide range of applications, including aluminum, copper, and precious metals casting. The company's crucibles are made from high-quality materials that are engineered to withstand the extreme heat and corrosive nature of the molten metals. [Company] offers a variety of crucible shapes and sizes to meet the specific needs of its customers, and its team of experts is always available to provide guidance and support in choosing the right crucible for each application.The company's crucibles are manufactured using advanced technologies and processes to ensure consistency and reliability. Each crucible undergoes rigorous testing and quality control procedures to guarantee its performance in the casting process. The high-quality materials and precision manufacturing techniques employed by [Company] result in crucibles that offer excellent thermal shock resistance, high thermal conductivity, and long service life.In addition to its standard crucible offerings, [Company] also specializes in custom crucible solutions to meet the unique needs of its customers. The company's team of experts works closely with customers to understand their specific requirements and develop tailored crucible solutions that deliver optimal performance and cost-efficiency. Whether it's a specific alloy, casting process, or environmental conditions, [Company] is dedicated to providing custom crucibles that exceed customer expectations.Furthermore, [Company] is committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing processes and materials to minimize its environmental footprint. Additionally, [Company] offers recycling programs for used crucibles, helping customers responsibly dispose of their crucibles and reduce waste.With its dedication to quality, innovation, and customer satisfaction, [Company] has established itself as a trusted partner in the casting industry. The company's crucibles are used by foundries, laboratories, and manufacturing facilities around the world, and [Company] has built a strong reputation for reliability and performance in the industry.In conclusion, the crucible plays a critical role in the casting process, and having the right crucible is essential to achieving high-quality castings. With its commitment to quality, innovation, and customer satisfaction, [Company] is a leading supplier of crucibles for casting applications. The company's extensive range of standard and custom crucible solutions, paired with its dedication to sustainability, make it the go-to choice for customers looking to optimize their casting processes. As the industry continues to evolve, [Company] remains at the forefront, driving innovation and delivering superior crucible solutions to meet the changing needs of the market.

Discover the Benefits of Induction Heating for Graphite Crucibles

Induction Heating Graphite Crucible, a Revolutionary Advancement in MetallurgyIn the world of metallurgy, technology and innovation continue to drive progress and efficiency. One of the latest advancements in the industry is the induction heating graphite crucible, which is revolutionizing the way metal is melted and cast. This groundbreaking technology is making waves in the manufacturing and metalworking sector, and is providing a more efficient and cost-effective solution for companies around the world.The induction heating graphite crucible is a product of innovative engineering and cutting-edge technology. It utilizes the principles of electromagnetic induction to generate heat within the crucible, allowing for precise and controlled melting of metals. This technology has several advantages over traditional methods of melting and casting metal, including faster melting times, energy efficiency, and improved temperature control.The induction heating graphite crucible is designed to withstand the extreme temperatures and conditions required for melting and casting metal. Its high thermal conductivity and resistance to thermal shock make it an ideal choice for a wide range of applications, from small-scale metalworking operations to large-scale industrial production.The use of induction heating technology also offers environmental benefits, as it minimizes the release of harmful emissions and reduces energy consumption compared to traditional heating methods. This makes the induction heating graphite crucible a more sustainable and environmentally friendly option for metalworking and manufacturing processes.One company at the forefront of this technology is {Company Name}, a leading manufacturer and supplier of induction heating equipment and graphite crucibles. With a strong focus on research and development, {Company Name} has been at the forefront of bringing this innovative technology to the market, providing customers with state-of-the-art solutions for their metalworking needs.{Company Name} offers a range of induction heating graphite crucibles that are designed to meet the specific requirements of different industries and applications. Whether it's for melting and casting precious metals in the jewelry industry, producing high-quality alloys in the automotive sector, or manufacturing specialized components for the aerospace industry, {Company Name} has the expertise and experience to deliver tailored solutions to its customers.The induction heating graphite crucibles offered by {Company Name} are known for their exceptional quality, durability, and performance. They are engineered to withstand the rigors of high-temperature operations and provide consistent and reliable results, making them a trusted choice for customers worldwide.In addition to its innovative products, {Company Name} also provides comprehensive support and technical assistance to its customers. Its team of experts is dedicated to helping customers optimize their metalworking processes and achieve the best possible results with the use of induction heating technology and graphite crucibles.The induction heating graphite crucible has already made a significant impact on the metallurgy industry, and its potential for further advancements and applications is vast. As technology continues to evolve, it is clear that this innovative solution will play a crucial role in shaping the future of metalworking and manufacturing.With its commitment to excellence and innovation, {Company Name} is poised to continue leading the way in the development and implementation of induction heating technology and graphite crucibles, providing customers with the tools they need to stay ahead in an ever-changing industry.In conclusion, the induction heating graphite crucible represents a significant advancement in metallurgical technology, offering a more efficient, sustainable, and environmentally friendly solution for melting and casting metal. With companies like {Company Name} leading the way, the future looks bright for the widespread adoption and application of this groundbreaking technology in the global metalworking and manufacturing industry.

High-quality Graphite Electrode Used in Industrial Applications

Graphite Used As ElectrodeGraphite has long been a popular material in the manufacturing industry due to its unique properties and versatility. One of its lesser-known applications is as an electrode in various industries including the metal, semiconductor, and battery sectors. As the demand for high-quality electrodes continues to rise, companies like {Company Name} have been at the forefront of utilizing graphite for this purpose.{Company Name} is a leading manufacturer and supplier of graphite products, with a strong focus on research and development to create innovative solutions for various industries. The company’s expertise in graphite has allowed them to develop high-performance electrodes that have garnered attention from a wide range of industries.The use of graphite as an electrode has become increasingly popular due to its excellent electrical conductivity, thermal stability, and resistance to corrosion. These properties make graphite an ideal choice for applications that require high performance and reliability. In addition, graphite electrodes are known for their ability to withstand high temperatures, making them suitable for use in demanding manufacturing processes.One of the key industries that benefit from the use of graphite electrodes is the metal industry. In the production of steel and other metal alloys, graphite electrodes play a crucial role in the electric arc furnace (EAF) process. The electrodes are used to generate the intense heat required to melt the raw materials and facilitate the chemical reactions necessary for the production of high-quality metals. With the increasing demand for high-performance steel and other metal products, the need for reliable graphite electrodes has been on the rise.In the semiconductor industry, graphite electrodes are used in various applications including the production of silicon and other semiconductor materials. The high purity and thermal stability of graphite make it an ideal choice for use in the manufacturing processes of semiconductor devices. As the demand for semiconductors continues to grow, the use of graphite electrodes is expected to increase accordingly.Furthermore, the growing popularity of electric vehicles and renewable energy storage systems has led to a surge in demand for high-quality graphite electrodes for use in lithium-ion batteries. Graphite is a key component in the anode of lithium-ion batteries, and its use as an electrode plays a critical role in the performance and longevity of these energy storage systems. As the global demand for electric vehicles and renewable energy solutions continues to rise, the need for reliable and high-performance graphite electrodes will become even more pronounced.{Company Name} has been at the forefront of meeting this rising demand for graphite electrodes, leveraging its expertise and state-of-the-art manufacturing facilities to produce high-quality products that meet the stringent requirements of various industries. The company’s commitment to research and development has allowed them to continuously improve their graphite electrode products, ensuring that they remain at the forefront of technological advancements in the industry.In addition to its focus on product innovation, {Company Name} also places a strong emphasis on sustainability and environmental responsibility in its manufacturing processes. The company’s use of advanced manufacturing techniques and its strict adherence to environmental regulations have made them a trusted partner for companies looking for sustainable and eco-friendly graphite electrode solutions.As the demand for high-quality graphite electrodes continues to rise across various industries, companies like {Company Name} are expected to play a pivotal role in meeting this demand and driving innovation in the field. With their expertise in graphite and their commitment to excellence, {Company Name} is well-positioned to continue leading the way in the development and manufacturing of graphite electrodes for the industries of the future.

Learn About the Uses of Silica Crucibles

Silica Crucible Use in Various Industries: A Sustainable Solution for High-Temperature ApplicationsIn the world of industrial manufacturing and laboratory research, the use of silica crucibles has become an essential component for high-temperature applications. These crucibles are widely used in industries such as metal casting, glass manufacturing, chemical synthesis, and advanced materials research.Silica crucibles are made from high-purity silica, which is a natural compound that is abundant in the earth's crust. The use of silica crucibles offers several advantages, including high thermal shock resistance, excellent chemical stability, and low thermal expansion. These properties make silica crucibles an ideal choice for containing and processing materials at extreme temperatures.One of the leading suppliers of silica crucibles, {}, has been at the forefront of providing high-quality crucibles to industries around the world. With a strong focus on research and development, {} has developed a wide range of silica crucibles that cater to the diverse needs of its customers.The company's commitment to sustainability and environmental responsibility is evident in its manufacturing processes, where it employs advanced technologies to minimize energy consumption and reduce waste generation. By using sustainable practices in its production facilities, {} ensures that its silica crucibles have a minimal impact on the environment while delivering superior performance.The versatility of silica crucibles makes them indispensable in a wide range of applications. For instance, in the metal casting industry, silica crucibles are used for melting and casting various metals, including aluminum, copper, and silver. The high thermal shock resistance of silica crucibles enables them to withstand rapid temperature changes, making them an ideal choice for metal casting processes.In the field of glass manufacturing, silica crucibles play a crucial role in the production of high-quality glass products. The exceptional chemical stability of silica crucibles ensures that they do not contaminate the molten glass, leading to the production of flawless glass products that meet stringent quality standards.Furthermore, in chemical synthesis and materials research, silica crucibles are utilized for conducting experiments at high temperatures, facilitating the synthesis of novel compounds and materials. The inert nature of silica crucibles makes them suitable for handling a wide range of chemical reagents, ensuring the purity of the final products.With the rise of advanced technologies and the demand for sustainable manufacturing practices, the use of silica crucibles is expected to grow significantly in the coming years. As industries continue to seek solutions that offer both performance and environmental benefits, silica crucibles are poised to become an integral part of their operations.In conclusion, the use of silica crucibles has become synonymous with sustainable manufacturing and high-temperature applications. With its exceptional properties and low environmental impact, silica crucibles have emerged as a preferred choice for industries seeking to achieve greater efficiency and sustainability in their operations.As a leading supplier of silica crucibles, {}, remains committed to meeting the evolving needs of its customers while upholding the highest standards of quality and sustainability. With continued research and development, {} is poised to play a key role in shaping the future of high-temperature applications across various industries.

Durable and High-Quality Metal Melting Crucible for Your Industrial Needs

Metal Melting Crucible is a leading manufacturer of high-quality crucibles and other melting products for the metal casting industry. Their products are designed to withstand extreme temperatures and provide excellent heat conductivity, making them ideal for melting and pouring various metals, such as gold, silver, aluminum, and copper.The company was established in [year] and has since grown to become a trusted supplier of melting crucibles to foundries, metal casting workshops, and jewelry manufacturers worldwide. Metal Melting Crucible is known for its commitment to quality and innovation, with a strong focus on developing advanced materials and manufacturing techniques to meet the evolving needs of the industry.One of the company's flagship products is their [product name] crucible, which is specially designed for melting gold and silver. It is made from a high-quality graphite material that can withstand the high temperatures required for melting precious metals. The crucible's unique design also allows for efficient heat transfer, ensuring even melting and consistent casting results.In addition to their standard crucible products, Metal Melting Crucible also offers custom manufacturing services to meet specific customer requirements. They work closely with their clients to develop tailored solutions for their metal melting needs, whether it be for specialized alloys, large-scale production, or unique casting processes.Metal Melting Crucible is committed to sustainability and environmental responsibility, and their products are manufactured using eco-friendly processes and materials. Their crucibles are designed to have a long lifespan, reducing the need for frequent replacements and minimizing waste. The company also invests in research and development to explore new ways of improving energy efficiency and reducing emissions in the metal casting industry.In recent news, Metal Melting Crucible has announced the launch of a new line of high-capacity crucibles, designed specifically for large-scale metal casting operations. These crucibles are made from a durable and heat-resistant material that can withstand the intense heat and pressure involved in melting and pouring large quantities of metal. The new product line is expected to cater to the growing demand for high-capacity melting products in the metal casting industry, offering customers a reliable and efficient solution for their production needs.With a strong commitment to quality, innovation, and sustainability, Metal Melting Crucible continues to be a leading provider of melting crucibles and related products. Their dedication to customer satisfaction and their ability to adapt to the changing needs of the industry solidify their position as a trusted and respected supplier in the metal casting market.As the company looks to the future, they remain focused on expanding their product range, exploring new materials and manufacturing techniques, and strengthening their partnerships with customers and industry stakeholders. Metal Melting Crucible is poised to continue its growth and success as a premier supplier of melting products for the metal casting industry.

Crucible for Furnace: Exploring the Key Ingredient for Efficient Melting and Heating

Crucible for Furnace: Enhancing Industrial Efficiency and SafetyIn the world of industrial manufacturing, innovation is essential for progress and success. One crucial area where innovation plays a significant role is in the development of high-quality crucibles for furnaces. These crucibles are instrumental in a range of industries, from metal melting and casting to glass production and chemical processing. In this article, we will explore the advancements made by an industry-leading company in the field of crucible manufacturing while removing the specific brand name in compliance with the request.Crucibles, traditionally made of materials such as clay, graphite, or ceramic, are an indispensable component of various manufacturing processes. They withstand extremely high temperatures and harsh chemical environments while ensuring the integrity of the materials they contain. Consequently, choosing the right crucible is vital for optimizing productivity, maintaining product quality, and ensuring the safety of workers and equipment.With a proven track record of excellence, this company has cemented its position as a pioneer in providing cutting-edge crucibles tailored to meet the diverse needs of industrial applications. Through ongoing research and development, they have introduced several innovative solutions that have revolutionized the crucible manufacturing industry.To achieve optimal performance, they offer crucibles made from advanced materials that exhibit exceptional thermal shock resistance, corrosion resistance, and mechanical strength. These improved crucibles enable manufacturers to operate at higher temperatures over longer periods, significantly enhancing efficiency and productivity. By reducing downtime and the frequency of crucible replacements, businesses can streamline their operations and increase profitability.Furthermore, the company understands the importance of safety in industrial settings. To address this crucial aspect, they have developed crucibles that are equipped with innovative features to minimize the risk of accidents. Enhanced thermal insulation and efficient heat distribution technologies ensure the outer surface of the crucibles remains relatively cool, reducing the potential for burn injuries. Additionally, improved handling systems and ergonomic designs have been incorporated into the crucibles, making them easier to use and reducing the chances of accidents during material transfer.Beyond the physical characteristics of the crucibles, this company also places significant emphasis on sustainability. Recognizing the global focus on reducing carbon footprints and advancing environmental stewardship, they have implemented measures to develop crucibles that are eco-friendly and contribute to a greener planet. This includes utilizing recyclable materials, reducing energy consumption during manufacturing, and providing options for responsible recycling of used crucibles. Their commitment to sustainable practices aligns with the evolving values of contemporary industries and positions them as an industry leader in comprehensive and responsible manufacturing.Collaboration and customer-centricity are central to the company's ethos. Recognizing the unique requirements of different industries, they work closely with their clients to develop customized crucibles that meet specific needs. By pooling together their expertise and insights, they empower manufacturers to optimize their processes and achieve superior results. This close relationship with customers has enabled the company to gain valuable insights into evolving industry trends and requirements, driving continuous improvement in crucible design and performance.Furthermore, their commitment to customer satisfaction extends beyond the initial purchase. With a global network of service centers staffed by experienced professionals, they offer prompt technical support, maintenance, and replacement services. This comprehensive after-sales service ensures that customers can rely on the company's crucibles for long-term, trouble-free operations, maximizing returns on their investment.In conclusion, crucibles for furnace applications play a pivotal role in numerous industries, and manufacturers must choose high-quality crucibles that enhance efficiency, safety, and sustainability. This industry-leading company, with its innovative approaches and commitment to customer satisfaction, has set new standards in crucible manufacturing. By continually pushing the boundaries of what is possible, they have established themselves as an indispensable partner for businesses seeking to harness the full potential of their manufacturing processes.