- Home

- Copper Vs Graphite Electrode

Copper vs Graphite Electrode: A Comprehensive Comparison | Manufacturer

Introducing the finest quality electrodes in the market, Wenzhou Future Import & Export Co., Ltd., a renowned manufacturer based in China. We proudly present our latest innovation - Copper vs Graphite Electrode. Designed to offer superior performance and maximize efficiency, our electrodes are the ultimate solution for a wide range of industries.

The Copper vs Graphite Electrode offers exceptional conductivity and durability, making it suitable for various applications such as electric arc furnaces and electrical discharge machining. With excellent thermal and electrical conductivity, copper electrodes ensure precise and consistent results in your operations. On the other hand, the graphite electrodes provide excellent resistance to high temperatures and chemical reactions, making them ideal for demanding environments.

Our electrodes are meticulously designed and crafted using advanced technology and quality materials, ensuring exceptional performance and longevity. We prioritize customer satisfaction and offer competitive prices, making our products accessible to a wide range of clients.

Choose Wenzhou Future Import & Export Co., Ltd. for the highest quality Copper vs Graphite Electrode. Contact us today to learn more about our products and secure the best deals. Let us exceed your expectations with our commitment to excellence and reliable solutions for all your electrode needs.

Zhejiang Rongda Energy Saving Technology CO.,LTD

Company News

Related News

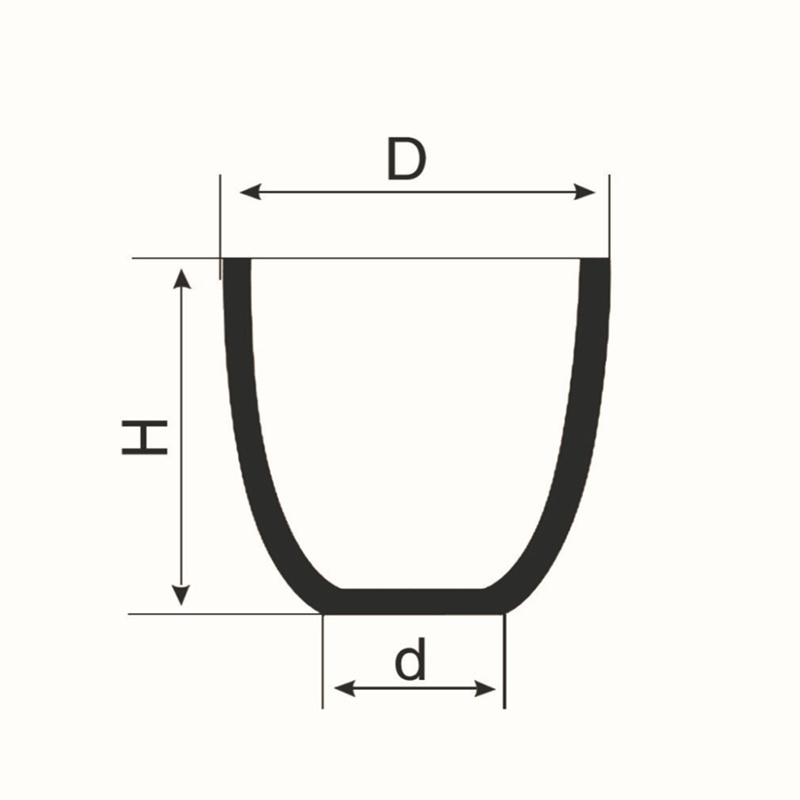

Clay Graphite Crucible

Get high-quality Clay Graphite Crucibles directly from our factory. Perfect for efficient melting and casting processes. Order today for reliable performance.

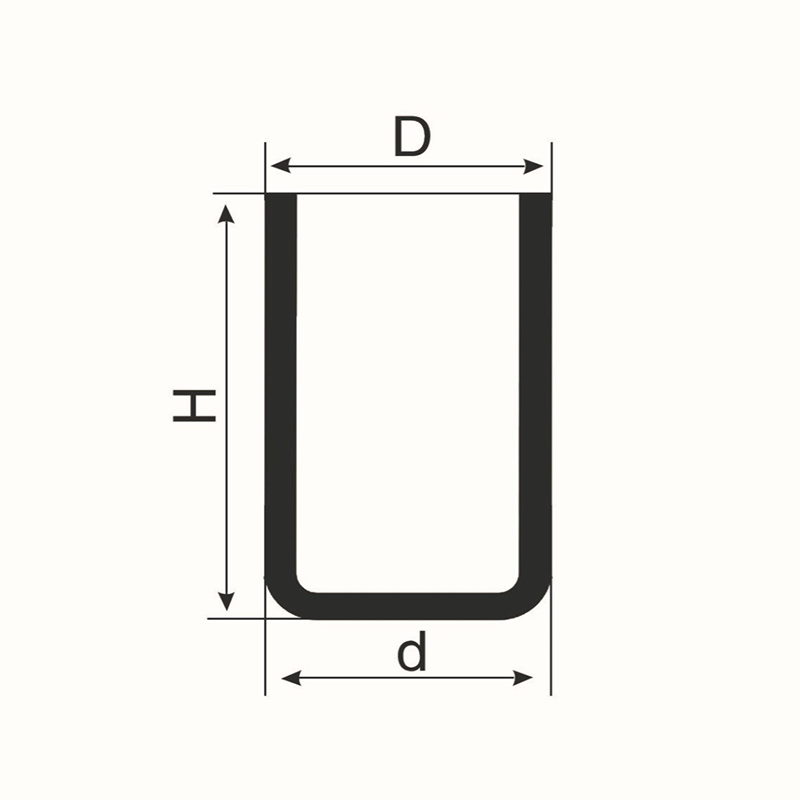

Graphite SiC Crucible

Shop high-quality Graphite SiC Crucibles directly from our factory. Get superior craftsmanship and durability for all your melting and casting needs.

Silicon Carbide Graphite Crucible

Looking for high-quality Silicon Carbide Graphite Crucibles? Look no further! We are a factory specializing in manufacturing and delivering top-notch crucibles.

Graphite Crucible With Spout

Shop our durable graphite crucibles with spout for your melting needs. As a factory-direct supplier, we offer high-quality products at competitive prices.

Graphite Slag Removal Rotor

Choose our Graphite Slag Removal Rotor for efficient and reliable slag removal. As a factory, we offer superior quality and competitive prices.

Custom made Graphite Clay Crucible

Discover our high-quality Custom Made Graphite Clay Crucible at our factory. We offer durable and reliable solutions for your melting needs. Shop Now!

Isostatic Pressure Silicon Carbide Crucible for Melting Metal

Shop high-quality isostatic pressure silicon carbide crucibles for melting metal. We are a leading factory, offering durable and reliable products.

Silicon Graphite Crucible

Get high-quality Silicon Graphite Crucibles directly from our factory. We are manufacturers offering durable and reliable crucibles for various industrial applications. Order now!

Clay Graphite Crucible with Spout

Shop our durable and efficient Clay Graphite Crucible with Spout - perfect for melting and pouring metals. Discover high-quality products from our factory.

Graphite Clay Crucible

Shop our premium Graphite Clay Crucible at unbeatable prices. As a factory, we guarantee superior quality and durability for all your melting needs.

Customized Graphite Composited Degassing Rotor Shaft

Buy high-quality customized graphite composite degassing rotor shafts from our factory. Improve your degassing process with our durable and efficient shafts.

Graphite Sagger

Buy high-quality Graphite Sagger from our factory. Customizable options available. Get superior heat resistance for your industrial processes.

Silicon Carbide Casting Crucible

Get high-quality Silicon Carbide Casting Crucibles direct from the manufacturer. Explore our factory-made crucibles for durable and efficient melting processes.

Clay Graphite Crucible for melting metal

Shop the highest quality Clay Graphite Crucibles for metal melting. We are a trusted factory, offering durable crucibles that ensure efficient and reliable results.

Thermocouple protection sleeve

High-quality Thermocouple Protection Sleeves designed for industrial use. We are a trusted factory offering durable and reliable solutions. Buy now!

- Copper vs Graphite Electrode: A Comparison and Overview - Wholesale Manufacturer

- Reviews

- Related Videos

When it comes to choosing between copper and graphite electrodes, the decision can greatly impact the performance of your electrical system. Copper electrodes offer excellent conductivity, ensuring efficient and reliable electrical connections. They are also durable and resistant to corrosion, guaranteeing a longer lifespan. On the other hand, graphite electrodes have their advantages too. They provide low electrical resistance and are better suited for high-temperature applications. The lightweight nature of graphite electrodes makes them easier to handle. Ultimately, the choice between copper and graphite electrodes will depend on your specific requirements. Consider factors such as electrical conductivity, corrosion resistance, and temperature limitations before making a decision.

When it comes to choosing between copper and graphite electrodes, there's no denying that both have their unique benefits. However, after careful consideration, I have to say that the copper electrodes take the crown for me. Their exceptional conductivity and durability make them the go-to choice for various applications. Whether it's in welding, electrical discharge machining, or electroplating, copper electrodes consistently deliver top-notch results. They provide a stable and efficient electrical connection, ensuring reliable performance. Furthermore, their resistance to extreme temperatures and corrosion guarantees a longer lifespan compared to graphite electrodes. While graphite electrodes have their advantages, the undeniable superiority of copper electrodes makes them the ultimate winner in this comparison.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours