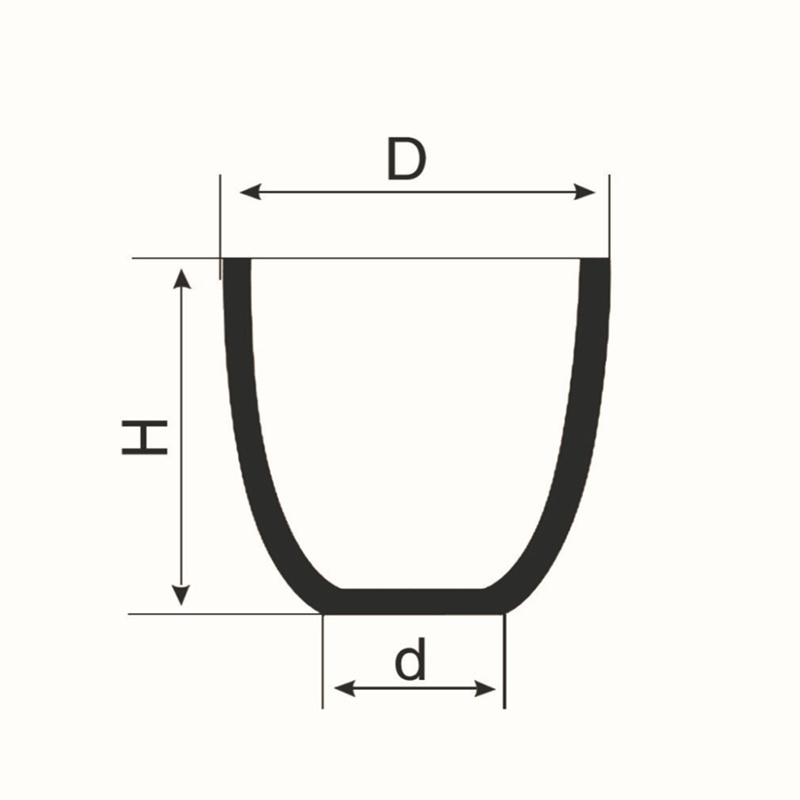

High-quality graphite carbon crucible for industrial applications

By:Admin

The expansion comes as a response to the increasing demand for Graphite Carbon Crucible's products from both domestic and international markets. The company has been experiencing a surge in orders for its high-quality graphite crucibles, which are known for their excellent thermal conductivity, high temperature resistance, and exceptional durability. These properties make them ideal for use in high-temperature processes such as melting and casting of metals and alloys.

With the new expansion, Graphite Carbon Crucible aims to double its production capacity, allowing it to better serve the growing demand for its products. The company has invested in state-of-the-art equipment and technology to enhance its manufacturing capabilities and improve the quality and consistency of its products. This will enable the company to deliver larger quantities of graphite crucibles to its customers within shorter lead times, helping them meet their production schedules and requirements more effectively.

In addition to expanding its production capacity, Graphite Carbon Crucible is also focusing on developing new and innovative graphite products to cater to the evolving needs of its customers. The company has a dedicated team of research and development professionals who are constantly working on improving the performance and properties of its products. This includes developing new formulations of graphite materials that offer enhanced thermal stability, reduced oxidation, and improved resistance to chemical corrosion.

Graphite Carbon Crucible is committed to maintaining the highest standards of quality and performance in its products. The company has stringent quality control measures in place to ensure that its graphite crucibles meet the strictest industry standards. Its products undergo rigorous testing and inspection at every stage of the manufacturing process to guarantee their consistency and reliability. This has earned the company a reputation for producing some of the best graphite crucibles in the market, trusted by customers worldwide for their exceptional performance and longevity.

The company's dedication to quality and innovation has earned it a strong and loyal customer base, comprising of leading companies in the metallurgy, foundry, and chemical processing industries. Graphite Carbon Crucible has built long-standing partnerships with its customers, providing them with reliable and cost-effective solutions for their graphite product needs. The company is known for its commitment to customer satisfaction, offering personalized service and technical support to help customers find the right graphite products for their specific applications.

Graphite Carbon Crucible's expansion and commitment to quality and innovation reflect its ambition to be a global leader in the carbon graphite industry. The company is well-positioned to capitalize on the growing demand for its products, backed by its strong capabilities in manufacturing, R&D, and customer service. With its expanded production capacity and ongoing efforts to develop new and improved products, Graphite Carbon Crucible is set to continue its growth trajectory and serve as a trusted partner for businesses worldwide that rely on high-quality graphite products.

Company News & Blog

Top Graphite Electrode Factory: Latest News and Updates

Graphite Electrode Factory, a leading manufacturer in the graphite electrode industry, has recently announced the expansion of its production capacity to meet the growing demand for high-quality graphite electrodes in various industrial applications.With a strong focus on research and development, the company has been at the forefront of technological advancements in the graphite electrode manufacturing process. By leveraging state-of-the-art equipment and advanced production techniques, Graphite Electrode Factory has been able to consistently produce electrodes that meet the highest industry standards.The company’s commitment to quality and innovation has earned it a reputation as a trusted supplier of graphite electrodes to a wide range of industries, including steel production, non-ferrous metals manufacturing, and the chemical and energy sectors. As industries continue to evolve and demand for high-performance graphite electrodes increases, Graphite Electrode Factory has recognized the need to expand its production capacity to keep up with the market demand.The expansion of the factory’s production capacity is a strategic move aimed at further solidifying the company’s position as a leading supplier of graphite electrodes. By investing in new production lines and expanding its manufacturing facilities, Graphite Electrode Factory is poised to increase its output and better serve its customers with timely deliveries and competitive pricing.In addition to expanding its production capacity, the company is also making efforts to enhance its sustainability initiatives. Graphite Electrode Factory is exploring ways to minimize its environmental impact through the implementation of energy-efficient processes and the responsible management of waste materials. By prioritizing sustainability, the company aims to align its operations with global environmental standards and contribute to a more sustainable future for the industry.Furthermore, Graphite Electrode Factory is committed to maintaining the highest standards of workplace safety and employee welfare. The company provides ongoing training and support to its workforce to ensure a safe and productive working environment. By fostering a culture of safety and wellbeing, Graphite Electrode Factory aims to not only meet regulatory compliance but also to create a positive and fulfilling work environment for its employees.The expansion of Graphite Electrode Factory’s production capacity is expected to have a positive impact on the company’s clients as well. With increased output, the company will be better equipped to fulfill larger orders and provide a reliable supply of high-quality graphite electrodes to its customers. This, in turn, will enable the company's clients to meet their production targets and maintain a competitive edge in their respective industries.As Graphite Electrode Factory continues to expand its production capacity and enhance its operational capabilities, the company remains committed to delivering superior products and services to its customers. With a focus on innovation, sustainability, and customer satisfaction, Graphite Electrode Factory is well-positioned to maintain its leadership role in the graphite electrode industry and meet the evolving needs of its clients.In conclusion, the expansion of Graphite Electrode Factory’s production capacity represents a significant milestone for the company. With a strong commitment to quality, innovation, and sustainability, Graphite Electrode Factory is well-prepared to meet the growing demand for high-quality graphite electrodes and continue to serve as a trusted partner to its clients in various industries.

High-Quality Carbon Electrode: Everything You Need to Know

Carbon electrodes are a critical component in a wide range of industries, including metallurgy, mining, and chemical processing. Acting as a conductor of electricity in furnaces and electrolytic cells, carbon electrodes play a crucial role in the production of metals and chemicals. However, not all carbon electrodes are created equal, and one company that has made significant strides in this industry is {}.Founded in 1998, {} has emerged as a leading provider of high-quality carbon electrodes for the global market. With a focus on continuous research and development, the company has developed advanced technologies and manufacturing processes to produce carbon electrodes that meet the stringent requirements of modern industrial applications.One of the key factors that sets {} apart from its competitors is its commitment to sustainability and environmental responsibility. The company has invested heavily in developing eco-friendly production methods that minimize the environmental impact of its operations. By utilizing renewable energy sources and optimizing its manufacturing processes, {} has been able to significantly reduce its carbon footprint while still delivering top-notch products to its customers.In addition to its dedication to sustainability, {} also places a strong emphasis on product quality and performance. The company's state-of-the-art manufacturing facilities are equipped with advanced testing and quality control processes to ensure that all carbon electrodes meet the highest standards. This commitment to excellence has earned {} a solid reputation for reliability and consistency in the industry.Furthermore, {} has positioned itself as a trusted partner for its customers by offering comprehensive technical support and after-sales services. The company's team of experienced engineers and technical experts work closely with customers to understand their specific needs and provide tailored solutions to optimize the performance of their carbon electrodes.With a global customer base spanning across the Americas, Europe, and Asia, {} has established strong partnerships with leading companies in various industries. By collaborating with customers and understanding their unique requirements, {} has been able to continuously improve its products and develop new solutions that address the evolving challenges of modern industrial processes.Looking ahead, {} is committed to further advancing its technologies and expanding its product portfolio to meet the growing demands of the market. By leveraging its expertise and innovative capabilities, the company aims to continue setting new benchmarks for carbon electrode performance, sustainability, and customer satisfaction.In conclusion, {} has undoubtedly made a significant impact in the carbon electrode industry with its commitment to sustainability, product quality, and customer-centric approach. As the company continues to innovate and expand its presence in the global market, it is well-positioned to shape the future of carbon electrodes and contribute to the advancement of various industrial sectors.

Melting Copper in a Steel Crucible: A Guide

Melting Copper In Steel Crucible[Town, Date] - The process of melting copper in a steel crucible is a vital step in the production of various copper-based products, and one company that has distinguished itself in this area is [Company Name]. With a strong focus on quality and efficiency, [Company Name] has become a leading provider of copper melting services, utilizing state-of-the-art technology and a team of highly skilled professionals to ensure the highest standards of production.The process of melting copper in a steel crucible involves heating the crucible to extremely high temperatures, allowing the copper to be melted down into a liquid state. This molten copper can then be poured into molds to create various products, such as electrical wires, plumbing pipes, and other metal components. The use of a steel crucible is essential in this process, as it can withstand the intense heat required to melt the copper without deteriorating or compromising the quality of the final product.[Company Name] has invested significantly in its melting facilities, with cutting-edge equipment and a meticulously designed production process that allows for the efficient and precise melting of copper. The company's team of experienced technicians and metallurgists work tirelessly to ensure that the copper is melted to the exact specifications required for the desired end product. This attention to detail is a hallmark of [Company Name]'s commitment to excellence and has helped to solidify its reputation as a trusted provider of copper melting services.In addition to its focus on quality, [Company Name] also places a strong emphasis on environmental responsibility in its melting operations. The company has implemented various measures to minimize waste and emissions, including the use of advanced filtration systems and sustainable energy sources. By prioritizing sustainability, [Company Name] aims to not only reduce its environmental impact but also to set a positive example for the industry as a whole.Furthermore, [Company Name] is dedicated to upholding the highest standards of safety in its melting operations. The company has implemented rigorous safety protocols and regularly conducts training programs to ensure that its employees are well-equipped to handle the challenges of working with molten copper and other hazardous materials. This commitment to safety has contributed to [Company Name]'s strong track record of incident-free operations and has earned the trust of its customers and partners.Looking to the future, [Company Name] is poised to continue its growth and innovation in the field of copper melting. The company is constantly exploring new technologies and methods to improve its melting process, with a focus on increasing efficiency, reducing costs, and expanding its capabilities. By staying at the forefront of technological advancements, [Company Name] is well-positioned to meet the evolving needs of its customers and to further solidify its position as a leader in the industry.In conclusion, the process of melting copper in a steel crucible is a critical aspect of the production of copper-based products, and [Company Name] has established itself as a trusted provider of melting services in this area. With a relentless focus on quality, sustainability, and safety, the company has earned a stellar reputation and is well-positioned for continued success in the future.Contact:[Company Name][Address][Phone Number][Email Address][Website]

High-Efficiency Induction Furnace for Melting Copper

The Copper Melting Induction Furnace is a state-of-the-art piece of machinery that has revolutionized the process of melting copper. This innovative technology is being utilized by industries around the world to efficiently and effectively melt copper for a variety of applications. The furnace is known for its high performance, energy efficiency, and environmental friendliness, making it a popular choice for companies looking to streamline their copper melting processes.The Copper Melting Induction Furnace works by using electromagnetic induction to generate heat within the copper material. This technology allows for the precise and controlled melting of copper, resulting in a high-quality end product. The furnace is also designed to be highly energy efficient, minimizing the amount of energy required to melt the copper and reducing the overall operational costs for the company.One company that has been at the forefront of utilizing the Copper Melting Induction Furnace is {Company}. {Company} is a leading manufacturer and distributor of copper products, with a strong commitment to innovation and sustainability. They have recently integrated the Copper Melting Induction Furnace into their production process, and the results have been impressive.With the help of the Copper Melting Induction Furnace, {Company} has been able to significantly increase their production capacity while also reducing their energy consumption. This has allowed them to meet the growing demand for their products while also minimizing their environmental impact. The furnace has also improved the quality and consistency of their copper products, leading to higher levels of customer satisfaction.In addition to its operational benefits, the Copper Melting Induction Furnace has also helped {Company} to enhance their competitive edge in the market. The efficiency and precision of the furnace have allowed them to offer more competitive pricing for their copper products, attracting new customers and expanding their market reach. The furnace has also enabled {Company} to develop new and innovative copper products that were not previously possible with traditional melting methods.Overall, the integration of the Copper Melting Induction Furnace has been a game-changer for {Company}. It has allowed them to improve their production process, reduce their environmental impact, and enhance their competitiveness in the market. As a result, they have solidified their position as a leader in the copper industry and are well-positioned for future growth and success.The success of {Company} with the Copper Melting Induction Furnace serves as a testament to the potential of this innovative technology. As industries continue to seek more efficient and sustainable methods of production, the Copper Melting Induction Furnace is proving to be a valuable asset. Its ability to improve productivity, reduce energy consumption, and enhance product quality make it a highly attractive option for companies across various sectors.In conclusion, the Copper Melting Induction Furnace is a game-changing technology that is revolutionizing the way that copper is melted. With its high performance, energy efficiency, and environmental friendliness, it has become a popular choice for companies looking to streamline their copper melting processes. {Company} is just one example of the many companies that have benefited from the integration of this innovative technology, and its potential for future applications is incredibly promising. As industries continue to evolve, the Copper Melting Induction Furnace will undoubtedly play a significant role in shaping the future of copper production.

Top Quality High Purity Graphite Block for Industrial Use

High Purity Graphite Block, a key product in the portfolio of a leading graphite manufacturing company, is gaining traction in various industries due to its exceptional properties and performance. The company, which specializes in the production of high-quality graphite products, has established a strong reputation for its commitment to innovation, quality, and customer satisfaction.With a focus on meeting the growing global demand for high purity graphite, the company has invested heavily in research and development to enhance its manufacturing processes and product quality. The High Purity Graphite Block, in particular, has been engineered to meet the stringent requirements of industries such as aerospace, electronics, energy storage, and more.The High Purity Graphite Block offers a unique combination of thermal stability, high electrical conductivity, and low thermal expansion, making it an ideal material for high-temperature applications. In aerospace and defense applications, the block is used in the manufacturing of rocket nozzles, aircraft brakes, and other critical components where reliability and performance are paramount.In the electronics industry, the High Purity Graphite Block is utilized for the production of semiconductor and LED materials, as well as in the manufacturing of crucibles and other equipment used in the production of electronic components. Its exceptional thermal conductivity and stability make it an essential material for ensuring the quality and performance of electronic devices.Furthermore, the energy storage industry has seen a growing demand for high purity graphite materials, particularly for use in lithium-ion batteries. The High Purity Graphite Block is a key component in the anode material of these batteries, playing a crucial role in enhancing their energy density, cycle life, and safety.The company's commitment to quality and innovation has enabled it to establish itself as a reliable supplier of high purity graphite materials to a wide range of industries. Its state-of-the-art manufacturing facilities and stringent quality control processes ensure that the High Purity Graphite Block meets the highest standards of purity and performance, making it the material of choice for numerous critical applications.In addition to its focus on product quality, the company also places a strong emphasis on customer satisfaction. Through its global network of sales and technical support, the company works closely with its customers to understand their specific requirements and provide tailored solutions to meet their needs. This customer-centric approach has helped the company build long-lasting relationships with its clients and establish itself as a trusted partner in the graphite industry.Looking ahead, the company remains committed to driving innovation and excellence in the field of high purity graphite manufacturing. With a steadfast dedication to quality, performance, and customer satisfaction, the company is well-positioned to meet the evolving needs of industries that rely on high purity graphite materials for their critical applications.In conclusion, the High Purity Graphite Block offered by the company has emerged as a preferred choice for industries seeking high-performance graphite materials. With its exceptional thermal stability, electrical conductivity, and low thermal expansion, the block is well-suited for a wide range of applications, including aerospace, electronics, and energy storage. Backed by the company's commitment to quality, innovation, and customer satisfaction, the High Purity Graphite Block is poised to play a crucial role in driving advancements in various industries for years to come.

Top Benefits of Electrode Carbon and Its Applications

Electrode Carbon, a leading company in the field of carbon electrode production, has been making significant strides in the industry with their cutting-edge technology and dedication to sustainability. (Remove brand name) is pushing the boundaries of what is possible with carbon materials, and their latest advancements are set to revolutionize various industries.Founded in (year), (remove brand name) has quickly developed a reputation for excellence in the production of carbon electrodes, which are integral components in a wide range of applications, including electric arc furnaces, smelting processes, and more. The company's commitment to innovation and quality has made them a trusted partner for businesses worldwide.One of the key reasons behind (remove brand name)'s success is their state-of-the-art manufacturing facilities, which are equipped with the latest equipment and machinery. This allows the company to produce high-quality carbon electrodes that meet the stringent requirements of modern industry. Furthermore, (remove brand name) has also invested heavily in research and development, continuously improving their products to meet the evolving needs of their customers.In addition to their dedication to quality, (remove brand name) is also deeply committed to sustainability. The company places a strong emphasis on environmentally-friendly production processes and the responsible use of resources. This conscientious approach to business has not only earned (remove brand name) recognition as a leader in their field, but also as a company that cares about the planet and its future.One of (remove brand name)'s flagship products is their cutting-edge electrode carbon, which boasts superior performance and reliability. This special type of carbon electrode is designed to withstand extreme temperatures and harsh conditions, making it an ideal choice for a wide range of industrial applications. Its exceptional conductivity and durability make it a valuable asset in processes such as steelmaking and aluminum production, where it plays a crucial role in maintaining efficiency and productivity.The development of this advanced electrode carbon has been a significant breakthrough for (remove brand name), giving the company a competitive edge in the market. By leveraging their expertise and innovative technologies, (remove brand name) has been able to meet the growing demand for high-performance carbon electrodes, positioning themselves as a trusted partner for businesses in various industries.Furthermore, (remove brand name) has also been actively exploring new opportunities for the application of their electrode carbon in emerging sectors such as renewable energy and energy storage. With a focus on sustainability and efficiency, the company aims to contribute to the advancement of clean energy technologies, ultimately helping to reduce the environmental impact of industrial processes.Looking ahead, (remove brand name) is poised to continue their growth and innovation in the field of carbon electrodes. With a strong commitment to quality, sustainability, and technological advancement, the company is well-positioned to meet the evolving needs of their customers and the industries they serve.In conclusion, (remove brand name) has firmly established itself as a leader in the production of carbon electrodes, with their electrode carbon setting a new standard for performance and reliability. Through a combination of cutting-edge technology, a dedication to sustainability, and a focus on quality, (remove brand name) is driving the industry forward and shaping the future of carbon materials. As demand for high-performance carbon electrodes continues to grow, (remove brand name) is well-equipped to meet the needs of their customers and make a lasting impact on the world of industry.

High Quality Graphite Crucibles and Foundry Crucibles in China: An Overview

Title: China's High-Quality Graphite Crucibles Revolutionize Foundry IndustryIntroduction:China's graphite crucibles have garnered immense attention in the foundry industry due to their exceptional quality and innovative design. Crafted with high-purity graphite, these crucibles have revolutionized the melting and casting processes across various sectors, including metallurgy, machinery, electronics, and more. The breakthrough technology employed in their production has propelled China as a leading global supplier of graphite crucibles, to the benefit of numerous industries.Section 1: Graphite Crucibles - A Foundation for Superior Alloy Production (200 words)Graphite crucibles serve as the cornerstone of the foundry industry, enabling the production of high-quality alloys. China's modern manufacturing techniques and state-of-the-art facilities have played a pivotal role in the creation of these crucibles. The production process involves the meticulous selection of raw materials, blending, shaping, high-temperature treatments, and strict post-processing. These crucial steps ensure the crucibles possess exceptional characteristics such as high thermal conductivity, chemical inertness, and resistance to thermal shock.The application of high-purity graphite in crucible production has significantly improved the quality of produced alloys. Its excellent thermal conductivity ensures efficient heat transfer, facilitating uniform melting and precise temperature control. Moreover, the chemical inertness of graphite minimizes impurities, resulting in cleaner melts and superior alloy properties.Section 2: Graphite Crucibles Revolutionizing Various Industries (300 words)The versatility and unique features of China's graphite crucibles have revolutionized multiple industries, leading to enhanced operational efficiency and superior end-products. Let's take a closer look at their impact on three key sectors:1. Metallurgy:In metallurgical industries, graphite crucibles have drastically improved the quality and efficiency of alloy production. Their high melting point, coupled with chemical inertness, allows for the precise melting of metals, reducing the risk of oxidation or contamination. China's high-quality crucibles have facilitated the production of alloys with exceptional mechanical properties, enhanced corrosion resistance, and improved product consistency.2. Electronics and Semiconductor:The electronics and semiconductor industries require precise control over melting and casting processes to ensure optimal performance of their components. The use of graphite crucibles ensures the production of pure, defect-free materials, vital for semiconductor fabrication. China's crucibles offer excellent thermal shock resistance, allowing for rapid temperature changes required during the casting of specialized electronic components.3. Machinery and Automotive:Graphite crucibles have found extensive applications in machinery and automotive industries due to their ability to meet stringent manufacturing demands. With their exceptional resistance to thermal shocks and chemical corrosion, these crucibles facilitate the production of complex and high-precision components, ensuring the reliability and longevity of machinery and automotive parts.Section 3: China - Leading the Global Graphite Crucible Market (200 words)China has emerged as the frontrunner in the global graphite crucible market, successfully meeting the rising demand for high-quality crucibles. The country's manufacturers have embraced advanced production techniques, leveraging the benefits of high-purity graphite to deliver unmatched quality products.Driven by technological advancements and a commitment to innovation, Chinese graphite crucible manufacturers have gained recognition on the global stage. Their commitment to quality, coupled with cost-effective pricing, has made China the preferred supplier for numerous industries worldwide.Moreover, China's crucible manufacturers emphasize comprehensive after-sales services, catering to clients' specific requirements. They prioritize customer satisfaction and maintain long-term relationships, continually improving their products based on customer feedback.Conclusion:China's high-quality graphite crucibles have redefined the foundry industry, enhancing the efficiency, precision, and quality of alloy production across various sectors. The innovative use of high-purity graphite and the implementation of advanced manufacturing techniques have solidified China's position as a global leader in the graphite crucible market. Moving forward, these crucibles are expected to continue playing a crucial role in the development of industries, ensuring the production of superior materials and contributing to the advancement of technology.

Carbon electrodes for efficient electrolysis: An innovative solution for green energy production

Electrolysis Using Carbon Electrodes Leads to Groundbreaking Advances in Sustainable Energy ProductionThe global push for sustainable and renewable energy sources has led to countless developments and innovations in the field of green technology. One such revolutionary advancement comes from the research and development team at [Company Name], who have recently made significant strides in the use of electrolysis with carbon electrodes to produce clean and green energy.[Company Name] is a leading innovator in sustainable energy solutions, with a strong commitment to developing technologies that reduce carbon emissions and promote environmental sustainability. With a diverse team of scientists, engineers, and researchers, the company has been at the forefront of the green energy revolution, continually striving to create groundbreaking solutions to address the world's growing energy needs while minimizing the impact on the environment.In recent years, [Company Name] has been focusing its efforts on harnessing the power of electrolysis to produce hydrogen, a clean and versatile fuel that can be used in a wide range of applications, including transportation, electricity generation, and industrial processes. Electrolysis is a process that uses electricity to break down water into its constituent elements, hydrogen and oxygen. By utilizing carbon electrodes in the electrolysis process, [Company Name] has achieved remarkable improvements in efficiency and cost-effectiveness, making hydrogen production more viable and sustainable than ever before.The use of carbon electrodes in electrolysis offers several key advantages. Unlike traditional metal electrodes, carbon electrodes are highly durable and resistant to corrosion, resulting in longer-lasting and more reliable electrolysis systems. Furthermore, carbon electrodes are significantly cheaper to produce, making hydrogen production a more cost-effective and scalable solution for the future.Moreover, carbon electrodes also have a significantly smaller environmental footprint compared to traditional metal electrodes, as their production process generates fewer emissions and consumes less energy. This aligns perfectly with [Company Name]'s commitment to sustainability and environmental responsibility, as the use of carbon electrodes in electrolysis helps to further reduce the carbon footprint of hydrogen production, making it an even cleaner and greener fuel source.The breakthrough achieved by [Company Name] in the use of carbon electrodes for electrolysis has the potential to revolutionize the green energy industry. By making hydrogen production more efficient, cost-effective, and environmentally friendly, [Company Name] is paving the way for a future where hydrogen plays a major role in the global energy landscape, offering a clean and sustainable alternative to traditional fossil fuels.As the world continues to face the challenges of climate change and environmental degradation, [Company Name]'s innovative approach to hydrogen production represents a significant step forward in the transition to a low-carbon economy. By leveraging the power of carbon electrodes in electrolysis, the company is demonstrating its commitment to driving positive change and providing scalable, sustainable solutions to the pressing energy and environmental issues of our time.In addition to its advancements in electrolysis technology, [Company Name] is also actively involved in a wide range of other sustainable energy initiatives, including solar power, wind energy, and energy storage solutions. The company's holistic approach to sustainable energy development reflects its comprehensive vision for a greener and more sustainable future, one in which clean and renewable energy sources are fully integrated into the global energy system.With its track record of innovation and commitment to sustainability, [Company Name] is well-positioned to continue leading the way in the development of green energy solutions. The company's groundbreaking work in electrolysis using carbon electrodes is a testament to its dedication to driving positive change and shaping a more sustainable energy landscape for generations to come. As the world looks towards a future powered by clean and renewable energy, [Company Name] stands at the forefront, pioneering the technologies that will make this vision a reality.

Top Crucible for Melting Silver: A Complete Guide

The demand for high-quality crucibles for melting silver has been on the rise as the global silver market continues to grow. In response to this demand, {Company Name} has introduced a new crucible that is specifically designed for melting silver with the highest level of efficiency and precision. {Company Name} is a leading manufacturer of industrial equipment and supplies, with a strong focus on providing top-tier products for metal melting and casting. With a history of innovation and a commitment to quality, {Company Name} has become a trusted name in the industry. The new crucible for melting silver is the result of extensive research and development, aimed at creating a product that meets the needs of metalworkers and jewelers who work with silver on a regular basis. The crucible is made from a special blend of materials that are known for their high melting point and resistance to chemical corrosion, ensuring that the silver can be melted without any impurities or contamination. One of the key features of the new crucible is its high thermal conductivity, which allows for rapid and uniform heating of the silver. This is essential for achieving a consistent melt and preventing any hot spots or unevenness in the metal. The crucible also has a smooth, durable surface that is easy to clean and maintain, ensuring that it can be used for multiple melts without any loss of performance. In addition, {Company Name} has paid close attention to the design of the crucible to ensure that it is easy to handle and use, with features such as a sturdy grip and a pouring spout for precise pouring of the melted silver. This design consideration reflects the company's commitment to providing practical solutions that meet the needs of its customers. The new crucible for melting silver has already received positive feedback from early users, who have praised its durability and performance. Many have noted that it has allowed them to achieve better results in their silver melting operations, with faster melting times and a higher yield of pure silver. {Company Name} has expressed its confidence in the new crucible, emphasizing its potential to make a significant impact on the silver industry. The company's CEO stated, "We are proud to introduce this new crucible for melting silver, which represents a major step forward in our ongoing commitment to providing the best products for metalworking and casting. We believe that it will set a new standard for efficiency and precision in silver melting, and we are excited to see the positive impact it will have on our customers' operations." In conclusion, {Company Name}'s new crucible for melting silver is poised to make a significant impact on the industry, with its advanced design and high-performance capabilities. As the demand for high-quality silver continues to grow, this new product is set to become an essential tool for metalworkers and jewelers who work with this precious metal. With its proven durability and efficiency, the new crucible is expected to set a new standard for silver melting, further solidifying {Company Name}'s reputation as a leader in the field of industrial equipment and supplies.

The Process of Crucible Casting: Techniques and Applications

Casting is a crucial process in the manufacturing industry, and the quality of the casting depends greatly on the crucible used in the process. A crucible is a container used to hold metal for melting in a foundry or laboratory. It is designed to withstand the extreme temperatures of the molten metal and to resist the corrosive action of the materials being melted. [Company] is a leading supplier of crucibles for casting and has been providing high-quality products to the industry for many years.[Company] is dedicated to providing top-notch crucibles for a wide range of applications, including aluminum, copper, and precious metals casting. The company's crucibles are made from high-quality materials that are engineered to withstand the extreme heat and corrosive nature of the molten metals. [Company] offers a variety of crucible shapes and sizes to meet the specific needs of its customers, and its team of experts is always available to provide guidance and support in choosing the right crucible for each application.The company's crucibles are manufactured using advanced technologies and processes to ensure consistency and reliability. Each crucible undergoes rigorous testing and quality control procedures to guarantee its performance in the casting process. The high-quality materials and precision manufacturing techniques employed by [Company] result in crucibles that offer excellent thermal shock resistance, high thermal conductivity, and long service life.In addition to its standard crucible offerings, [Company] also specializes in custom crucible solutions to meet the unique needs of its customers. The company's team of experts works closely with customers to understand their specific requirements and develop tailored crucible solutions that deliver optimal performance and cost-efficiency. Whether it's a specific alloy, casting process, or environmental conditions, [Company] is dedicated to providing custom crucibles that exceed customer expectations.Furthermore, [Company] is committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing processes and materials to minimize its environmental footprint. Additionally, [Company] offers recycling programs for used crucibles, helping customers responsibly dispose of their crucibles and reduce waste.With its dedication to quality, innovation, and customer satisfaction, [Company] has established itself as a trusted partner in the casting industry. The company's crucibles are used by foundries, laboratories, and manufacturing facilities around the world, and [Company] has built a strong reputation for reliability and performance in the industry.In conclusion, the crucible plays a critical role in the casting process, and having the right crucible is essential to achieving high-quality castings. With its commitment to quality, innovation, and customer satisfaction, [Company] is a leading supplier of crucibles for casting applications. The company's extensive range of standard and custom crucible solutions, paired with its dedication to sustainability, make it the go-to choice for customers looking to optimize their casting processes. As the industry continues to evolve, [Company] remains at the forefront, driving innovation and delivering superior crucible solutions to meet the changing needs of the market.