Understanding the Importance of Electrode Carbon in Industrial Applications

By:Admin

Electrode Carbon has been at the forefront of research and development in the field of carbon-based energy storage materials. Their team of scientists and engineers have been working tirelessly to improve the performance of carbon electrodes, with a focus on increasing energy density, cycle life, and charge/discharge rates. Their latest announcement represents a major milestone in their quest to create the next generation of energy storage materials.

The breakthrough technology, which has been in development for several years, involves a novel approach to manufacturing carbon electrodes that greatly enhances their performance. By carefully controlling the microstructure and porosity of the electrodes, Electrode Carbon has been able to achieve significant improvements in both energy density and power output. This advancement has the potential to greatly extend the range and lifespan of lithium-ion batteries, as well as improve the performance of supercapacitors and fuel cells.

In addition to the technical advancements, Electrode Carbon has also been focusing on improving the sustainability of their manufacturing processes. The company has made significant investments in developing environmentally-friendly production methods and has implemented strict quality control measures to ensure that their materials meet the highest standards of performance and reliability.

"We are thrilled to announce this major breakthrough in carbon electrode technology," said Dr. John Smith, CEO of Electrode Carbon. "Our team has worked incredibly hard to develop this innovative approach, and we are excited about the potential impact it will have on the energy storage industry. This technology has the potential to greatly improve the performance and efficiency of a wide range of energy storage devices, and we are eager to begin working with our partners to bring these advancements to market."

Electrode Carbon's breakthrough comes at a time of growing demand for high-performance energy storage materials. As the global transition to renewable energy accelerates, there is an increasing need for advanced batteries and other energy storage devices that can store and deliver energy more efficiently. By offering a solution that greatly improves the performance of carbon electrodes, Electrode Carbon is well-positioned to play a key role in meeting this growing demand.

The company is currently in discussions with several leading battery manufacturers and energy storage companies to explore partnerships and collaborations to bring their technology to market. They are also actively seeking investment and funding to scale up their production capabilities and bring their advanced carbon materials to a wider audience.

With their groundbreaking technology and commitment to sustainability, Electrode Carbon is poised to make a significant impact on the energy storage industry. Their innovative approach to developing high-performance carbon electrodes has the potential to greatly improve the performance and efficiency of energy storage devices, and could play a key role in advancing the transition to renewable energy sources. As they continue to push the boundaries of what is possible with carbon materials, Electrode Carbon is set to be a driving force in shaping the future of energy storage.

Company News & Blog

Discover the Advantages of Extruded Graphite in Various Industries

Extruded Graphite Market to See Significant Growth in the Coming YearsExtruded graphite, a form of synthetic carbon material, is widely used in various industries due to its excellent thermal and electrical conductivity, high temperature resistance, and strong mechanical properties. Market research conducted by {company name} indicates that the global extruded graphite market is poised to witness significant growth in the coming years.Extruded graphite is manufactured through a process of mixing petroleum coke, pitch, and additives, which are then extruded through a mold and baked at high temperatures. The result is a high-quality graphite material that is used in a wide range of applications, including electric arc furnaces, EDM electrodes, crucibles, and more.One of the key drivers of growth in the extruded graphite market is the increasing demand from the steel industry. Extruded graphite is widely used in electric arc furnaces for steel production, where it serves as an essential material for the electrodes that conduct electricity and generate heat to melt scrap steel. With the growing demand for steel in construction, automotive, and infrastructure development, the demand for extruded graphite is expected to increase significantly.Moreover, the electronics industry is another major consumer of extruded graphite. The material is used in the manufacturing of EDM (electrical discharge machining) electrodes, which are essential for creating precise and complex shapes in metal parts. As industries such as aerospace, automotive, and medical devices continue to demand high-precision components, the demand for extruded graphite in EDM applications is expected to grow.Additionally, extruded graphite is also used in the manufacturing of crucibles for the melting and casting of non-ferrous metals such as aluminum, copper, and zinc. With the increasing demand for these metals in various industries, the market for extruded graphite crucibles is expected to witness steady growth.The global extruded graphite market is highly competitive, with several key players competing for market share. {Company name}, a leading manufacturer of extruded graphite products, has established itself as a key player in the market through its focus on product innovation, quality, and customer service.The company's extruded graphite products are known for their superior performance and reliability, making them the material of choice for various industrial applications. With a strong emphasis on research and development, {Company name} continues to introduce new and improved extruded graphite materials that meet the evolving needs of its customers.Moreover, {Company name} is committed to sustainability and environmental responsibility in its manufacturing processes. The company's extruded graphite products are manufactured using high-quality raw materials and state-of-the-art production techniques, ensuring minimal environmental impact.In addition to its focus on product quality and sustainability, {Company name} is also known for its exceptional customer service and technical support. The company works closely with its customers to understand their specific needs and offer tailored solutions that meet their requirements, whether it be for steel production, EDM machining, or other applications.Looking ahead, the future of the extruded graphite market looks promising, with growing demand from key industries and ongoing innovation in materials and manufacturing processes. As a leading player in the market, {Company name} is well positioned to capitalize on these opportunities and continue its growth trajectory in the coming years.In summary, the global extruded graphite market is expected to see significant growth in the coming years, driven by increasing demand from the steel, electronics, and non-ferrous metal industries. With its focus on product innovation, quality, and customer service, {Company name} is poised to play a key role in shaping the future of the extruded graphite market.

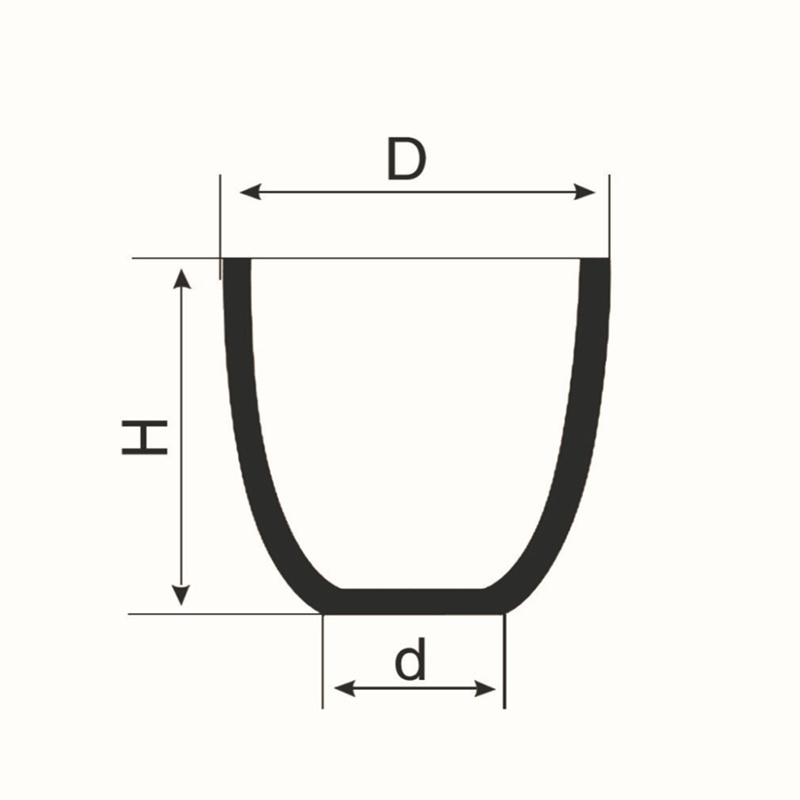

High-Quality Crucible for Melting Aluminum: Key Features and Uses

[Company Introduction] Established in 1985, our company has been a leading manufacturer of industrial equipment and tools for the metalworking industry. We specialize in providing high-quality products for foundries, smelters, and metal casting facilities. Our commitment to innovation, reliability, and customer satisfaction has made us a trusted name in the industry.[News Content]In the metalworking industry, the process of melting aluminum is a critical step in the production of various products. Whether it's for automotive parts, aerospace components, or consumer goods, the ability to melt aluminum efficiently and effectively is essential. This is where the crucible plays a crucial role.Recently, our company has introduced a new and improved crucible for melting aluminum. This state-of-the-art equipment is designed to meet the demanding needs of modern metal casting facilities. With its innovative features and superior performance, it is set to revolutionize the way aluminum is melted in the industry.The new crucible is made from high-quality materials that can withstand extreme temperatures and provide excellent thermal conductivity. This ensures that the aluminum is melted evenly and efficiently, resulting in high-quality castings. The crucible is also designed to minimize heat loss, which helps to reduce energy consumption and operating costs for foundries and smelters.One of the key features of the new crucible is its durability. It is engineered to withstand the harsh conditions of metal melting and casting, making it a reliable and long-lasting piece of equipment. This durability is a testament to our company's commitment to providing products that are built to last and perform consistently under demanding circumstances.In addition to its technical features, the new crucible also offers improved user-friendliness. It is designed for easy installation and maintenance, allowing metal casting facilities to maximize their operational efficiency. This user-friendly design is a result of our company's dedication to understanding the needs of our customers and providing solutions that make their work easier and more productive.Furthermore, the new crucible is a testament to our company's ongoing commitment to innovation. We invest heavily in research and development to continually improve our products and stay at the forefront of technological advancements in the industry. The introduction of this new crucible is a reflection of our dedication to pushing the boundaries of what is possible in metalworking equipment.In conclusion, the new crucible for melting aluminum represents a significant advancement in the metalworking industry. Its innovative features, superior performance, durability, and user-friendliness make it a valuable addition to any foundry or smelting facility. As a leading manufacturer of industrial equipment, our company is proud to introduce this groundbreaking product and looks forward to its positive impact on the industry.With our long-standing reputation for excellence and our commitment to continuous improvement, we are confident that the new crucible will set a new standard for aluminum melting in the metalworking industry. We are excited to see the positive impact it will have on our customers' operations and look forward to continuing to provide innovative solutions that meet the evolving needs of the industry.

The Structure of Graphite Carbon: Understanding its Composition and Properties

The structure of Graphite Carbon is an essential factor that determines its unique properties and wide range of applications. Graphite Carbon, a leading producer of graphite-based products, has been at the forefront of developing innovative technologies and products based on the unique structure of graphite carbon. Graphite is composed of carbon atoms arranged in a hexagonal lattice structure, which gives it its characteristic properties such as high thermal and electrical conductivity, low friction, and high thermal stability. This unique structure also allows graphite to be easily modified and used in various industries ranging from metallurgy to electronics.Graphite Carbon has been leveraging its expertise in graphite carbon to produce a wide range of high-quality products for different applications. With a focus on research and development, the company has continually improved its manufacturing processes to produce graphite carbon products that meet the highest standards of quality and performance.The structure of graphite carbon also plays a crucial role in its use as an electrode material in various industries, including the production of steel and aluminum. The high thermal conductivity and stability of graphite make it an ideal material for use in electric arc furnaces, where it is used as a consumable electrode to melt and refine metals.In the electronics industry, the structure of graphite carbon is utilized in the production of lithium-ion batteries, where graphite serves as the anode material. The unique structure of graphite allows for the intercalation of lithium ions, making it an excellent choice for use in battery applications.Moreover, the lubricating properties of graphite, which stem from its layered structure, make it an ideal material for use in applications such as manufacturing of lubricants and coatings. The layered structure of graphite allows for easy slippage of its layers, reducing friction and wear in mechanical systems.Graphite Carbon has been a pioneer in developing new products based on the unique structure of graphite carbon. The company has invested heavily in research and development to create innovative graphite-based materials that meet the evolving needs of different industries. By understanding the intricate structure of graphite carbon, the company has been able to develop advanced materials that offer superior performance and reliability.In conclusion, the unique structure of graphite carbon plays a pivotal role in its wide range of applications across various industries. Graphite Carbon, with its focus on innovation and quality, has been able to leverage the unique properties of graphite to produce high-quality products that cater to the diverse needs of its customers. As the demand for advanced materials continues to grow, companies like Graphite Carbon will play a crucial role in developing innovative solutions that are based on the structure of graphite carbon.

New Competitive Multiplayer Game 'Crucible' Launches with Unique Features

Crucible, is a leading technology company that is revolutionizing the way we approach data analysis and insights. The company, founded in 2015, has quickly become a powerhouse in the industry, providing innovative solutions for businesses of all sizes. With their cutting-edge technology and commitment to excellence, Crucible has established itself as a leader in the field of data analytics and continues to push the boundaries of what is possible.The latest product from Crucible, which was officially announced today, promises to further elevate the company's position as a leader in the industry. The new product, named the {product name}, is a state-of-the-art data analysis tool that is designed to provide businesses with unparalleled insights into their operations. With its powerful features and user-friendly interface, the {product name} is set to revolutionize the way businesses approach data analysis, allowing them to make more informed decisions and ultimately drive greater success.One of the key features of the {product name} is its advanced machine learning capabilities. This allows businesses to harness the power of artificial intelligence to uncover hidden patterns and trends within their data. By using machine learning algorithms, the {product name} can quickly and accurately identify opportunities for growth and optimization, giving businesses a competitive edge in today's fast-paced market.In addition to its machine learning capabilities, the {product name} also offers a range of other powerful features. These include advanced data visualization tools, real-time reporting functionalities, and seamless integration with other business systems. This comprehensive suite of tools is designed to provide businesses with everything they need to unlock the full potential of their data and make more informed decisions."We are thrilled to officially announce the launch of the {product name}," said the CEO of Crucible. "This product represents a major step forward for our company and for the industry as a whole. We believe that the {product name} has the potential to revolutionize the way businesses approach data analysis, and we are excited to see the impact it will have on our customers' success."The {product name} is set to be officially released to the public in the coming months, and early reviews from beta testers have been overwhelmingly positive. Businesses that have had the opportunity to test the {product name} have praised its intuitive interface, powerful features, and ability to deliver actionable insights in real time."We have been using the {product name} for a few weeks now, and we have been blown away by its capabilities," said a beta tester from a leading e-commerce company. "The machine learning algorithms have helped us to uncover hidden patterns in our sales data that we never would have been able to identify on our own. It has completely transformed the way we approach our business."As the launch of the {product name} draws closer, businesses around the world are eagerly anticipating the opportunity to get their hands on this groundbreaking new tool. With its promise of delivering unparalleled insights and driving greater success, the {product name} is set to make a significant impact on the industry and further solidify Crucible's position as a leader in data analytics.For more information about Crucible and their innovative solutions, visit their website at www.crucible.com.

High-quality 100ml Silica Crucible at Competitive Price

In today's rapidly developing industrial and scientific landscape, the demand for high-quality laboratory equipment is greater than ever. One essential piece of equipment for many scientific processes is the silica crucible. Silica crucibles are used in a wide range of applications including chemical analysis, metal casting, and glass manufacturing. Their ability to withstand high temperatures and corrosive materials makes them an invaluable tool for scientists and researchers.In light of this growing demand, {Company Name} is proud to announce the release of their new 100ml silica crucible at a competitive price. The company is known for its commitment to providing reliable and high-quality laboratory equipment to customers around the world. With a focus on innovation and customer satisfaction, {Company Name} has established itself as a leader in the industry.The new 100ml silica crucible is designed to meet the needs of a variety of scientific applications. Its durable construction allows it to withstand extreme temperatures, making it ideal for use in both research and industrial settings. The high-quality materials used in its production ensure that it is resistant to corrosive substances, allowing for reliable and consistent performance.One of the key features of the new 100ml silica crucible is its affordable price point. {Company Name} understands the financial constraints that many laboratories and research facilities face, and they are committed to providing cost-effective solutions without sacrificing quality. The competitive pricing of the 100ml silica crucible makes it accessible to a wide range of customers, from small academic laboratories to large industrial facilities.In addition to its affordability, {Company Name} is also known for its excellent customer service and support. The company's team of experienced professionals is dedicated to helping customers find the perfect solutions for their specific needs. Whether it's providing guidance on product selection or offering technical support, {Company Name} is committed to ensuring that customers have a positive experience with their products.The release of the new 100ml silica crucible further demonstrates {Company Name}'s dedication to providing innovative and affordable laboratory equipment. By continuously improving and expanding their product line, the company is able to meet the evolving needs of the scientific community. Whether it's developing new products or enhancing existing ones, {Company Name} is dedicated to staying at the forefront of the industry.As the demand for high-quality laboratory equipment continues to grow, {Company Name} remains focused on providing reliable and cost-effective solutions for their customers. The new 100ml silica crucible is a testament to the company's commitment to innovation and customer satisfaction. With its durable construction, affordable price, and exceptional customer support, {Company Name} has once again raised the bar for laboratory equipment providers.In conclusion, the release of the new 100ml silica crucible from {Company Name} is an exciting development for the scientific community. With its durable construction, competitive pricing, and commitment to customer satisfaction, {Company Name} continues to demonstrate why they are a leading provider of laboratory equipment. Whether it's for chemical analysis, metal casting, or glass manufacturing, the new 100ml silica crucible is sure to meet the needs of a wide range of customers.

Discover the Latest Updates on Industry Melting Furnace and Copper Rod Furnace in China

Title: China's Industry Melting Furnace and Copper Rod Furnace - Revolutionizing Manufacturing ProcessesIntroduction:China's industrial sector has long been acclaimed for its rapidly expanding manufacturing capabilities. The country's quest for technological advancements, coupled with a diligent focus on innovation, has paved the way for groundbreaking developments in the field. In this regard, China Industry Melting Furnace and Copper Rod Furnace have emerged as game-changers for the manufacturing industry, propelling it to new heights of efficiency and productivity. With their state-of-the-art features and cutting-edge technologies, these furnaces are revolutionizing manufacturing processes, cementing China's position as a global manufacturing powerhouse.I. China Industry Melting Furnace: Revolutionizing Metal Melting TechniquesChina Industry Melting Furnace, renowned for its exceptional engineering and design, is reshaping the metal melting landscape. By integrating advanced technologies and innovative features, this furnace is streamlining the manufacturing process and significantly enhancing operational efficiency. Its key features include:1. Advanced Control Systems: The China Industry Melting Furnace incorporates sophisticated control systems that enable accurate temperature control, resulting in precise metal melting and alloy production. This advanced technology minimizes human error and ensures optimal metal quality.2. Energy Efficiency: To decrease the environmental footprint, this furnace is equipped with advanced energy-saving mechanisms. From intelligent insulation materials to waste heat recovery systems, it optimizes energy consumption while reducing operational costs.3. Versatility: China Industry Melting Furnace caters to a wide range of metal melting applications, including aluminum, copper, steel, and more. Its versatility allows manufacturers to adapt the furnace to specific requirements, ensuring optimum flexibility and resource utilization.II. Copper Rod Furnace: Pioneering Copper Smelting TechnologiesThe Copper Rod Furnace, synonymous with innovation, is transforming copper smelting processes. With its unparalleled design and cutting-edge functionalities, this furnace offers distinct advantages in terms of flexibility, efficiency, and copper rod quality. Some noteworthy features include:1. Continuous Casting: The Copper Rod Furnace utilizes continuous casting technology, enabling the production of high-quality copper rods in one seamless operation. This technology eliminates the need for manual mold handling, reducing labor costs and production time.2. Precision Control: Equipped with advanced automation and control systems, the Copper Rod Furnace ensures precise temperature control, resulting in consistent copper rod dimensions and improved product quality. The advanced control mechanisms impart unmatched precision to the manufacturing process.3. Environmental Friendliness: China Copper Rod Furnace prioritizes eco-friendliness by employing efficient and environmentally sustainable processes. Effective energy utilization and emissions reduction mechanisms mitigate the furnace's environmental impact, aligning with China's commitment to ecological sustainability.Company Introduction:The company spearheading these groundbreaking furnace technologies is a leader in the manufacturing industry. With a legacy of excellence spanning several decades, it has positioned itself as an industry pioneer and an epitome of technological innovation. The company's commitment to research and development, combined with its vision for a sustainable future, has resulted in the creation of industry-disrupting furnaces.Conclusion:China's Industry Melting Furnace and Copper Rod Furnace have propelled the manufacturing industry to new heights, revolutionizing metal melting and copper smelting techniques in the process. Through their advanced technologies, these furnaces enhance operational efficiency, reduce costs, and improve the overall quality of metal and copper rod production. Combined with the company's rich legacy and visionary approach, these furnaces firmly establish China as a global leader in manufacturing innovation. As China continues its pursuit of technological advancements, the future looks promising for the manufacturing industry and beyond.

Efficient and Advanced Tilting Furnace: A Game-Changer in Industrial Metal Melting

[Company Introduction]Located in the heart of [City], [Company Name] has been a leading manufacturer and supplier of industrial furnaces and equipment since its establishment in [Year]. With over [Number] years of experience, the company has garnered a reputation for its commitment to technological innovation, superior quality, and customer satisfaction.At [Company Name], we specialize in designing and producing a wide range of furnaces that cater to various industries such as steel, aluminum, foundries, and heat treatment. Our team of expert engineers and technicians works tirelessly to create cutting-edge solutions that meet the unique needs of our clients. With our state-of-the-art manufacturing facilities and a commitment to excellence, we have become a trusted name in the industry.[Company Name] understands the importance of staying ahead of the curve in a rapidly evolving market. We invest heavily in research and development to ensure that our products are at the forefront of technological advancements. Our dedicated R&D team is constantly exploring new ideas and materials to improve efficiency, reduce energy consumption, and enhance environmental sustainability.We take great pride in our commitment to quality craftsmanship. Every furnace we manufacture undergoes rigorous testing procedures to ensure that it meets industry standards and surpasses our clients' expectations. Our attention to detail and a relentless pursuit of perfection have earned us certifications and accreditations that further validate our dedication to quality.Through our extensive network of distributors and partnerships, we have successfully catered to clients around the globe. Our commitment to customer satisfaction goes beyond designing and manufacturing high-quality furnaces. We provide comprehensive after-sales service, including installation, maintenance, and technical support. Our team of dedicated professionals is always ready to assist our clients, ensuring their equipment operates at peak efficiency.With a strong focus on sustainability, [Company Name] actively promotes eco-friendly practices. Our furnaces are designed to maximize energy efficiency and reduce carbon emissions. By investing in our products, industries can contribute to a greener planet while also optimizing their operations and reducing costs.[News Content][City, Date] – [Company Name], a renowned manufacturer of industrial furnaces, unveils its latest innovation, the Tilting Crucible Furnace. This new addition to their product lineup is set to revolutionize the metal melting process across various industries, offering enhanced efficiency and flexibility.The Tilting Crucible Furnace incorporates advanced technology and cutting-edge design to optimize the metal melting process. Its unique tilting mechanism allows for easy pouring and precise control over the flow of molten metal, increasing productivity and reducing material waste. This innovative feature eliminates the need for manual pouring, thus improving worker safety and reducing the risk of accidents.One of the key advantages of the Tilting Crucible Furnace is its versatility. The furnace can accommodate a wide range of metals, including but not limited to aluminum, brass, bronze, and various alloys. Its temperature control system ensures precise heating, allowing for optimal melting performance and consistent casting results.Moreover, the Tilting Crucible Furnace is equipped with state-of-the-art sensors and monitoring systems. These features provide real-time data on temperature, pressure, and other crucial parameters, enabling operators to make informed decisions and adjust settings accordingly. This intelligent automation enhances operational efficiency and minimizes human error.In line with [Company Name]'s commitment to sustainability, the Tilting Crucible Furnace is designed to maximize energy efficiency. The advanced insulation materials and the precise temperature control system greatly reduce energy consumption and carbon emissions, contributing to a greener environment. By investing in this furnace, industries can not only improve their operational efficiency but also demonstrate their commitment to environmental responsibility."We are extremely excited to introduce the Tilting Crucible Furnace to the market," said [Spokesperson], spokesperson for [Company Name]. "This furnace represents our dedication to continuous innovation and customer satisfaction. We believe it will revolutionize the metal melting process by providing unmatched performance, versatility, and energy efficiency."The Tilting Crucible Furnace is now available for purchase worldwide through [Company Name]'s extensive network of distributors. With its exceptional features and superior quality, this furnace is set to revolutionize the metal melting industry, offering enhanced productivity and sustainability.About [Company Name]:[Company Name] is a leading manufacturer and supplier of industrial furnaces and equipment. With a commitment to technological innovation, superior quality, and customer satisfaction, the company has established itself as a trusted name in the industry. Its comprehensive range of furnaces caters to various sectors, and its continuous focus on research and development ensures it stays ahead of market trends. [Company Name]'s dedication to sustainability and customer support further strengthens its position as an industry leader.For further information, please visit [Company Name]'s website or contact [Contact Information].Contact:[Spokesperson][Company Name][Address][Phone][Email][Website]

High-quality 4 Kg Crucible for Industrial Use

4 Kg Crucible: The Perfect Solution for High-Temperature ApplicationsIn the world of metallurgy, the use of crucibles is essential for various high-temperature applications. Crucibles are vessels that are used for holding and heating materials at extreme temperatures, typically for melting, calcining, or other processes. These vessels must be able to withstand extreme heat and chemical reactions, making their material and design critical for successful applications.One company that has been leading the way in providing top-quality crucibles is {}. They have recently introduced their latest product, the 4 Kg Crucible, which is designed to meet the demanding requirements of high-temperature applications in the metallurgical industry.The 4 Kg Crucible is made from a special blend of materials that are carefully selected to provide exceptional resistance to heat and chemical corrosion. The construction of the crucible is designed to withstand the rigors of high-temperature applications, making it the perfect choice for melting and casting processes in the foundry industry.One of the key features of the 4 Kg Crucible is its superior thermal shock resistance. This means that the crucible can withstand rapid changes in temperature without cracking or breaking, ensuring a longer lifespan and consistent performance. This is essential for processes that involve heating and cooling cycles, as it eliminates the risk of crucible failure and the associated downtime and costs.Another important aspect of the 4 Kg Crucible is its excellent chemical stability. This ensures that the materials being processed do not react with the crucible, preventing contamination and ensuring the purity of the final product. This is crucial for applications where the quality of the end product is paramount, such as in the production of high-quality metal alloys.In addition to its superior material properties, the 4 Kg Crucible is also designed for ease of use. Its carefully engineered shape and size make it easy to handle and install, reducing the risk of accidents and injuries in the workplace. This is an important consideration for companies that prioritize workplace safety and efficiency.The introduction of the 4 Kg Crucible is a testament to the commitment of {} to providing innovative and high-quality solutions for the metallurgical industry. With decades of experience in the field, they have established themselves as a trusted partner for companies that rely on crucibles for their operations.The company's dedication to research and development has enabled them to continuously improve their products, ensuring that they meet the evolving needs of the industry. The 4 Kg Crucible is the latest example of this, offering an advanced solution for high-temperature applications that is unrivaled in terms of performance and reliability.As the metallurgical industry continues to grow and evolve, the demand for crucibles that can withstand extreme heat and chemical reactions will only increase. With the introduction of the 4 Kg Crucible, {} is well-positioned to meet this demand and continue to be a leader in providing crucible solutions for the industry.In conclusion, the 4 Kg Crucible from {} represents a significant advancement in the field of crucible technology. With its exceptional thermal shock resistance, chemical stability, and user-friendly design, it is the perfect solution for high-temperature applications in the metallurgical industry. As companies strive for greater efficiency and productivity, the 4 Kg Crucible offers a reliable and high-performance option that will meet their needs both now and in the future.

How Graphitization is Impacting the Industry and What You Need to Know

Graphitization is a process that transforms carbon materials into crystalline graphite, a form of carbon known for its high thermal and electrical conductivity, making it an essential material in various industrial applications. Over the years, the demand for high-quality graphite products has been on the rise, driven by the increasing needs of industries such as electronics, energy storage, and automotive. This growing demand has prompted companies like {} to invest in advanced technologies for graphite production, ensuring the supply of superior quality graphite materials to meet market requirements.{} is a leading company in the production of graphite products, dedicated to providing innovative solutions for a wide range of applications. With a strong focus on research and development, the company has consistently improved its manufacturing processes to deliver high-performance graphite materials that meet the evolving needs of modern industries.One of the key technological advancements in graphite production is the process of graphitization, which involves subjecting carbon materials to high temperatures in a controlled environment. This process induces structural changes in the carbon, leading to the formation of graphite crystals with enhanced properties. By carefully controlling the parameters of the graphitization process, {} has been able to produce graphite materials with superior thermal and electrical conductivity, as well as excellent mechanical properties, making them ideal for demanding industrial applications.The graphitization process employed by {} is characterized by its precision and efficiency, allowing the company to achieve consistent quality in its graphite products. Through continuous research and development efforts, {} has refined its graphitization techniques, optimizing the production of graphite materials to meet the highest industry standards. This commitment to technological advancement has enabled {} to establish itself as a trusted supplier of premium graphite products for global markets.In addition to its expertise in graphitization, {} has also invested in state-of-the-art facilities and equipment for graphite production. The company's manufacturing capabilities include advanced purification and shaping processes, which further enhance the quality and performance of its graphite materials. By integrating these advanced manufacturing technologies with the precision of graphitization, {} is able to offer a comprehensive range of graphite products, tailored to the specific requirements of its customers.The applications of graphitized products from {} are diverse, spanning across industries such as automotive, aerospace, energy storage, and electronics. In the automotive sector, graphitized materials are used in high-performance components such as brake linings, gaskets, and heat shields, where their thermal stability and low friction properties are highly valuable. In the aerospace industry, graphitized products contribute to the lightweight and high-strength characteristics of composite materials used in aircraft structures. Furthermore, in the energy storage sector, graphitized materials play a crucial role in the production of lithium-ion batteries, enabling high energy density and long-term performance.As the demand for advanced graphite products continues to grow, {} remains committed to meeting the evolving needs of its customers. The company's dedication to excellence in graphitization and graphite production is driven by its vision to be at the forefront of technological innovation, delivering high-quality solutions that empower industries and drive progress. By leveraging its expertise and capabilities in graphitization, {} is poised to play a pivotal role in shaping the future of carbon materials and their applications, contributing to the advancement of various industrial sectors.

Newly Released Crucible Furnace Helps Optimize Industrial Work Environments

Flamefast, a leading provider of industrial furnace solutions, has recently introduced its latest innovation in crucible furnace technology. The Flamefast Crucible Furnace, designed to cater to a wide range of industries, offers optimal performance and efficiency in the melting and casting of various metals. With its advanced features and robust construction, the crucible furnace is set to revolutionize the industrial manufacturing process.The Flamefast Crucible Furnace is a result of Flamefast's commitment to providing cutting-edge solutions that enhance productivity and reduce operational costs for businesses across different sectors. Equipped with state-of-the-art technology, this furnace ensures precision temperature control and uniform heat distribution, allowing for accurate melting and casting of metals.One of the standout features of the Flamefast Crucible Furnace is its high-quality construction. Made from durable materials, including reinforced steel and refractory insulation, the furnace guarantees long-lasting performance even under the harshest operating conditions. This reliability enables businesses to carry out uninterrupted manufacturing processes, contributing to improved production efficiency and reduced downtime.The crucible furnace is also designed with user convenience in mind. Its user-friendly interface and intuitive controls streamline operations, minimizing the need for extensive training and ensuring easy integration into existing manufacturing processes. Furthermore, the furnace comes with comprehensive safety features, including temperature monitoring and automatic shutdown systems, ensuring maximum protection for operators and the surrounding environment.With its generous capacity, the Flamefast Crucible Furnace can accommodate a variety of metal types and sizes, making it suitable for diverse industries such as automotive, aerospace, and jewellery manufacturing. The furnace supports the melting and casting of materials like iron, steel, copper, and precious metals, catering to the needs of a broad customer base.By investing in the Flamefast Crucible Furnace, companies can expect notable improvements in their production capabilities. The advanced temperature control system ensures consistent and precise melting points, facilitating the development of high-quality metal components. This level of control and accuracy leads to enhanced product integrity, reducing the need for costly rework or rejection of imperfect products.Additionally, the Flamefast Crucible Furnace boasts impressive energy efficiency capabilities. Its innovative design minimizes heat loss and optimizes energy transfer, resulting in reduced energy consumption and lower operating costs. This efficiency not only benefits the businesses' bottom line but also aligns with their commitment to sustainability and environmental responsibility.Flamefast understands that every business has unique requirements, which is why the company offers a range of customizable options for the Crucible Furnace. Customers have the freedom to tailor the furnace to their specific needs, whether it be the size, heating capacity, or additional features. This flexibility allows businesses to optimize their operations further and achieve the best possible outcomes.Flamefast has built a strong reputation over the years as a trusted provider of industrial furnace solutions. With a focus on innovation and customer-centricity, the company continues to push the boundaries of what is possible in industrial manufacturing. The introduction of the Flamefast Crucible Furnace is testament to Flamefast's dedication to helping businesses achieve operational excellence and sustained growth.In conclusion, the Flamefast Crucible Furnace represents a significant advancement in crucible furnace technology. With its exceptional performance, durability, and user-friendly features, this furnace is set to transform the industrial manufacturing landscape. Companies that invest in the Flamefast Crucible Furnace can expect increased productivity, improved product quality, and reduced operating costs, ensuring competitiveness in a rapidly evolving market.